Spark Plug, Emmissions, Exhaust and Carburetor

Spark Plug, Emmissions, Exhaust and Carburetor

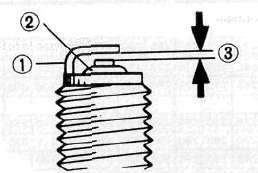

SPARK PLUG

1. Remove:

• Spark plug(s)

2. Inspect:

• Electrode (1) Wear/Damage — Replace.

• Insulator color (2)

3. Measure:

• Plug gap (3)

Use a Wire Gauge or Feeler Gauge. Out of specification — Regap.

0.7 ~ 0.8 mm (0.028 - 0.31 in)

Clean the plug with a spark plug cleaner if necessary-

Standard Spark Plug: BP8 ES (NGK) W24EP-U (NIPPONDENSO)

Before installing a spark plug, clean the gasket surface and plug surface.

4. Tighten:

• Spark plug(s)

20 Nm (2.0 mkg, 14ftlb)

NOTE:

Finger-tighten the spark plug(s) before torquing to specification.

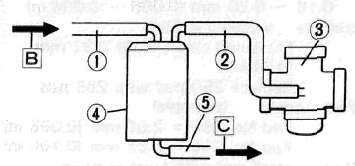

CANISTER (For California Only)

This model is equipped with a canister to prevent the discharging of fuel vapor into the atmosphere.

1. Inspect:

• Hoses (1) (2) (5) Cracks/Damage — Replace. Clog - Clean.

• Canister (4) Cracks/Damage — Replace.

3 Carburetor [B] From fuel tank [C] To atmosphere

A EMISSION HOSE ROUTING

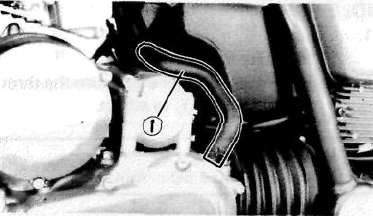

CRANKCASE VENTILATION SYSTEM

1. Inspect:

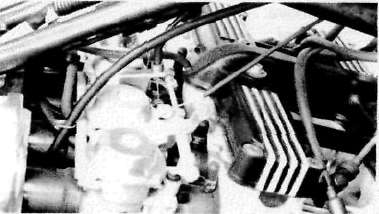

• Crankcase ventilation hose ® Cracks/Damage — Replace.

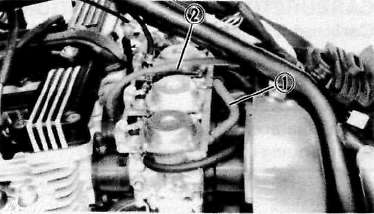

FUEL LINE

1. Inspect:

• Fuel hose (1)

• Vacuum hose (2) Cracks/Damage — Replace.

INTAKE MANIFOLD

1. Tighten:

• Carburetor clamps

• Carburetor joint bolts

2. Inspect:

• Carburetor joint

• Gaskets Cracks/Damage — Replace.

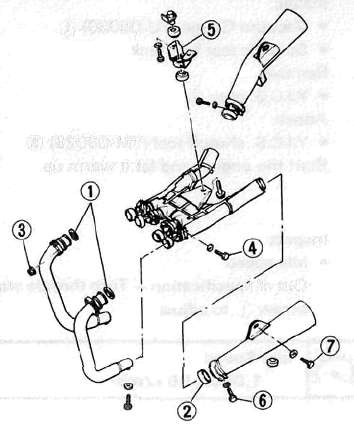

EXHAUST SYSTEM

1. Inspect:

• Exhaust pipe gasket(s) (1)

• Muffler clamp gasket(s) (2) Damage — Replace. Exhaust gas leakage — Repair.

2. Tighten:

• Exhaust pipe bolts

• Muffler bolts

Exhaust Pipe Flange (3) :

10 Nm (1.0 m-kg, 7.2ft-lb)

Exhaust Pipe Clamp (4) :

20 Nm (2.0 m-kg, 14ftlb)

Muffler Bracket (5) :

25 Nm (2.5 m-kg, 18 ft-lb)

Exhaust Chamber Mount (7) :

20 Nm (2.0 m-kg, 14 ft-lb)

Muffler Clamp (6) :

20 Nm (2.0 m-kg, 1 4 ft-lb)

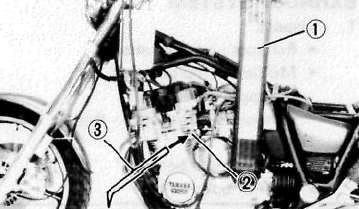

IDLE SPEED/CARBURETOR SYNCHRONIZATION

IDLE SPEED

1. Adjust

• Idle speed

Warm up the engine and turn the throttle stop screw (1) to adjust.

Idle Speed

1,050 + 50 r/min

Carburetor Adjustment.

Carburetors must be adjusted to open and close simultaneously.

NOTE:

Valve clearance must be set properly before synchronizing the carburetors.

1. Remove:

• Seat

• Fuel tank

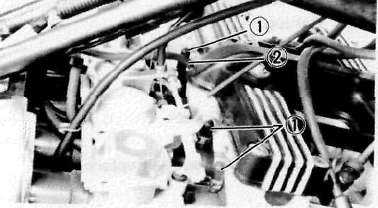

2. Disconnect:

• Vacuum plugs (1)

• Vacuum hose (2)

3. Install:

• Vacuum Gauge (YU-08030) (1)

• Suitable test fuel tank

4. Remove:

• Y.I.C.S. plug (2)

5. Attach:

• Y.I.C.S. shutoff tool (YM-08025) (3)

6. Start the engine and let it warm up.

7. Inspect:

• Idle speed

Out of specification — Turn throttle stop screw (1) to adjust.

Idle Speed

1,050 ±50 r/min

8. Adjust:

• Carburetor synchronization

Carburetor synchronization adjustment steps:

• Synchronize the carburetor No. 1 to the carburetor No. 2 by turning the synchronizing screw (1) until the both gauge readings are the same.

• Rev. the engine for a fraction of a second, two or three times, and check the synchronization again.

Vacuum Pressure at Idle Speed:

23.99 kPa (180 mm Hg, 7.09 in Hg)

Vacuum Synchronous Difference:

0.67 kPa (5 mm Hg, 0.2 in Hg)

• Repeat the above steps to synchronize the carburetor No. 4 to the carburetor No. 3 by turning the synchronizing screw (3) until the both gauge readings are the same.

• Repeat the same steps to synchronize No. 3 carburetor to No. 1 carburetor, then turn synchronizing screw (2) until both gauge readings are the same.