Clutch, Timing and Compression

Clutch, Timing and CompressionCLUTCH ADJUSTMENT

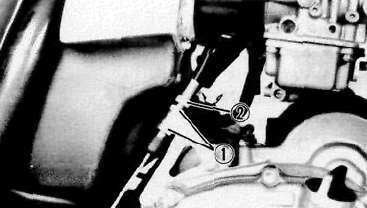

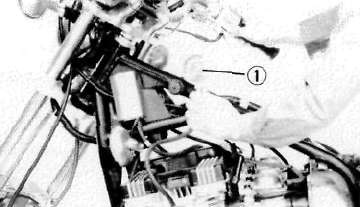

1. Loosen:

• Adjuster locknut (1)

2. Adjust:

• Clutch lever free play (3)

(by turning adjuster (2) in or out)

Free play:

2-3 mm (0.08 - 0.12 in)

If free play can not be adjusted, adjust by clutch cable length adjuster.

3. Loosen:

• Adjuster locknut (1)

4. Adjust:

• Clutch lever free play

(by turning clutch cable length adjuster (2) )

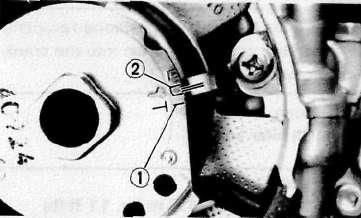

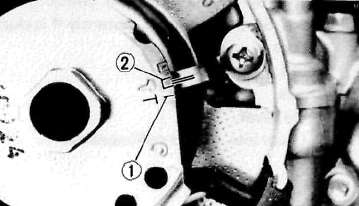

IGNITION TIMING CHECK

Flywheel is marked as follows:

(1) TDC for No. 1 cylinder

(2) Firing range for the No. 1 cylinder

1. Check:

• Ignition timing

Ignition timing check steps:

• Remove the cover.

• Connect the Timing Light (YM-33277) i to No. 1 cylinder spark plug lead.

• Warm up the engine and let it idle at the specified idle speed of 1,050 ± 50 r/min.

• Visually check the stationary pointer in the timing window to verify it is within the required firing range indicated on the flywheel.

Incorrect firing — Check timing plate and/or pickup assembly (tightness damage)

Refer to CHAPTER 6, "ELECTRICAL" for further information.

(1) TDC for No. 1 cylinder

(2) Firing range for the No. 1 cylinder

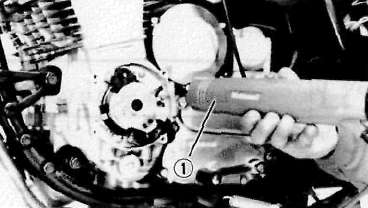

COMPRESSION PRESSURE MEASUREMENT

NOTE:

Insufficient compression pressure will result in performance loss.

1. Measure:

• Valve clearance

Out of specification — Adjust.

2. Warm up the engine.

3. Remove:

• Spark plugs

Compression pressure measurement steps:

• Install the Compression Gauge (YU-33223) (1) using an adapter.

• Crank over the engine with the electric starter (be sure the battery is fully charged) with the throttle wide-open until the compression reading on the gauge stabilizes.

• Check readings with specified levels (See chart).

Compression Pressure (at sea level):

Standard: 1,078 kPa (11 kg/cm2, 156 psi)

Minimum: 882 kPa (9 kg/cm2, 128 psi)

Maximum: 1,176 kPa (12 kg/cm2, 171 psi)

When cranking the engine, ground all of the spark plug leads to prevent sparking.

• Repeat the previous steps for the other cylinders.

• If pressure falls below the minimum level:

1. Squirt a few drops of oil into the affected cylinder.

2. Measure the compression again.

|

Compression Pressure (with oil introduced into cylinder) |

|

|

Higher than without oil |

Worn or damaged pistons |

|

Same as without oil |

Defective ring(s). valves, cylinder head gasket or piston is possible. |

|

Above maximum level |

Inspect cylinder head, valve surfaces, or piston crown for carbon deposits. |

NOTE:

The difference between the highest and lowest cylinder compression readings must not vary more than the specified value.

Difference Between Each Cylinder:

Less than 98 kPa (1 kg/cm2,14 psi)