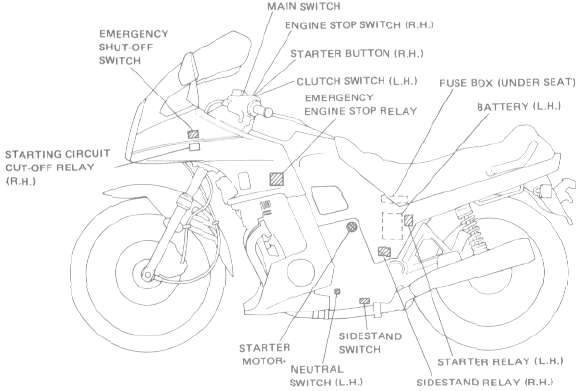

Electric Starting System

Electric Starting System

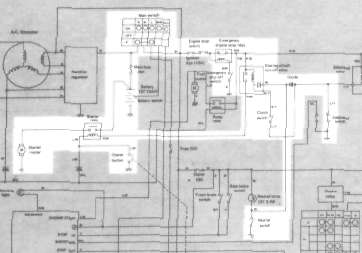

Above circuit diagram shows starter circuit in wiring diagram.

B. Starter Motor

1. Removal (see CHAPTER 3. "ENGINE DISASSEMBLY")

2. Inspection and repair

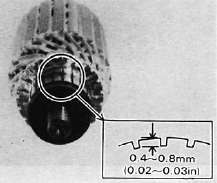

a. Check the outer surface of the commutator. If its surface is dirty, clean with # 600 grit sand paper.

b. The mica insulation between commutator segments should be 0.4 ~ 0.8 mm (0.02 ~ 0.03 in) below the segment level. If not, scrape to proper limits with appropriately shaped tool. (A hack saw blade can be ground to fit.)

NOTE:

Mica insulation of commutator must be undercut to ensure proper operation of commutator.

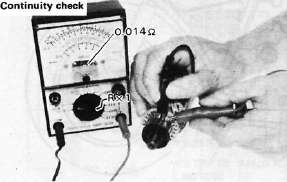

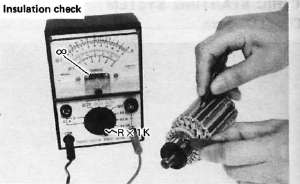

c. The starter's armature coil should be checked with an ohm meter for insulation breakdown (shorting to each other or to ground) and for continuity. Reference figure is given below.

Coil resistance: Armature coil: 0.014Ω at 20°C (68°F)

d. Check the front and rear cover bearings for damage. If damaged, the starter assembly must be replaced.

e. Check brush length. Replace brush if at, or near, limits.

Minimum brush length: 8.5 mm (0.33 in)

f. Check brush spring pressure. Compare it with a new spring. Replace the old spring if it is weak.

C. Starter Relay Switch

1. Inspection

a. Disconnect starter cable at the relay.

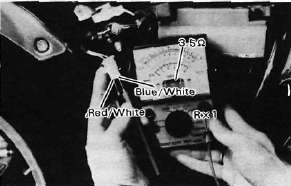

b. Connect pocket tester leads to the relay terminals (ohms x 1 scale).

c. Turn ignition to "ON" position, engine stop switch to "RUN" and change lever to "NEUTRAL".

d. Push the starter button. The relay should click once and the scale should read zero if it does not read zero, the relay must be replaced.

1. Battery lead wire (+)

2. Starter motor lead wire

e. If the relay does not click, check the wires from the starter button and from the battery (red/white, blue/white). Turn the ignition off. Use (ohms x 1) scale on tester. The resistance between these wires should be no more than 3.5Ω. If there is more resistance, the relay should be replaced.