D. Valve Spring and Lifters

1. Checking the valve springs

a.

This engine uses two springs of different sizes to prevent valve float

or surging. The valve spring specifications show the basic value

characteristics.

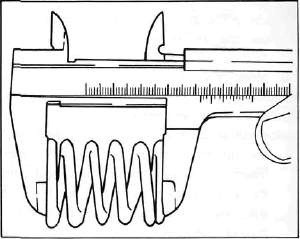

b. Even though

the spring is constructed of durable spring steel, it gradually loses

some of it's tension. This is evidenced by a gradual shortening of free

length. Use a vernier caliper to measure spring free length. If the

free length of any spring has decreased more than 2 mm (0.080 in) from

its specification replace it.

c.

Another symptom of a fatigued spring is insufficient spring pressure

when compressed. This can be checked using a valve spring compression

rate gauge. Test each spring individually. Place it in the gauge and

compress the spring first to the specified compressed length with the

valve closed (all spring specifications can be found in the previous

section, Valve Spring), then to the length with the valve open. Note

the poundage indicated on the scale at each setting. Use this procedure

with the outer springs, then the inner springs.

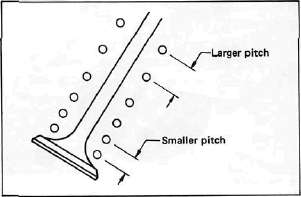

NOTE:

All valve springs must be installed with larger pitch upward as shown.

|

Valve Spring Specifications |

||

|

|

OUTER |

INNER |

|

Free length |

39.5 mm (1.55 in) |

35.9 mm (1.413 in) |

|

Installed length (valve closed) |

34.0 mm (1.339 in) |

31.0 mm (1.220 in) |

|

Installed pressure |

19.1 kg (42.1 lb) |

9.0 kg (19.8 1b) |

|

Allowable tilt from vertical |

1.6° |

|

2. Valve lifter

a.

Check each valve lifter for scratches or other damage. If the lifter is

damaged in any way, the cylinder head surface in which it rides is

probably also damaged. If the damage is severe, it may be necessary to

replace both the lifter and the cylinder head.

NOTE:

For proper valve lifter-to-head clearance, always install lifters on their original valves.

E. Camshafts, Cam chain and Cam Sprockets

1. Camshaft

a.

The cam lobe metal surface may have a blue discoloration due to

excessive friction. The metal surface could also start to flake off or

become pitted.

b. If any of the above wear conditions are readily visible, the camshaft should be replaced.

c.

Even though the cam lobe surface appears to be in satisfactory

condition, the lobes should be measured with a micrometer. Cam lobe

wear can occur without scarring the surface. If this wear exceeds a

pre-determined amount, valve timing and lift are affected. Replace the

camshaft if wear exceeds the limits.

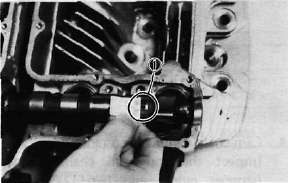

d.

Install the camshaft on the cylinder head. Place a strip of Plastigage

between camshaft and camshaft cap as illustrated (lengthwise along

camshaft). Tighten the nuts with specified torque. Remove the camshaft

cap and determine the clearance by measuring the width of the flattened

Plastigage.

Cap nut tightening torque: 1.0m-kg(7.2ft-lb)

1. Plastigage

NOTE

Do not turn camshaft when measuring clearance with Plastigage.

Camshaft-to-cap clearance:

|

Standard: |

0.020-0.054 mm |

|

|

(0.0008- 0.0021 in) |

|

Maximum: |

0.160 mm (0.006 in) |

If the camshaft-to-cap clearance exceeds specification, measure camshaft bearing surface diameter.

Bearing surface diameter:

|

Standard: |

24.967-24.980 mm |

|

|

(0.9830-0.9835 in) |

1) If camshaft diameter is less than specification, causing excessive clearance, replace camshaft.

2) If camshaft is within specification and camshaft-to-cap clearance is excessive, replace cylinder head.

2. Cam chain

Except

in cases of oil starvation, the cam chain wears very little. If the cam

chain has stretched excessively and it is difficult to keep the proper

cam chain tension, the chain should be replaced.

3. Cam sprockets

Check cam sprockets for obvious wear.

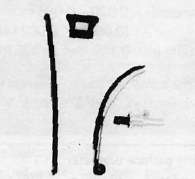

4, Cam chain dampers and tensioner

Inspect

the top cam chain damper (stopper guide) and two (2) vertical

(slipper-type) dampers for excessive wear. Any that shows excessive

wear should be replaced. Worn dampers may indicate an improperly

adjusted or worn-out cam chain.

- Printer-friendly version

- Log in to post comments