Generator, Starter and Pick-up Coil Reassembly

8. A.C. Generator

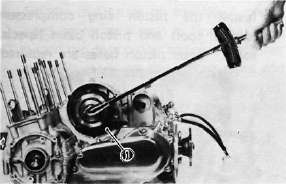

a. Install the rotor onto the shaft and tighten the bolt using the rotor holding tool (special tool) as shown.

1. Rotor holding tool

Tightening torque: 5.5 m-kg (39.8 ft-lb)

b. Install the stator coil assembly onto the crankcase and align the grooves on the stator core with the bolt holes on the crankcase.

- Read more about Generator, Starter and Pick-up Coil Reassembly

- Log in to post comments