Turbo Lubrication System

LUBRICATION SYSTEM

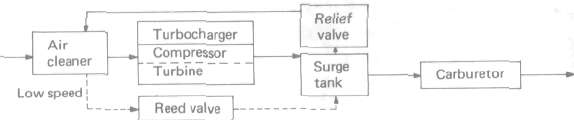

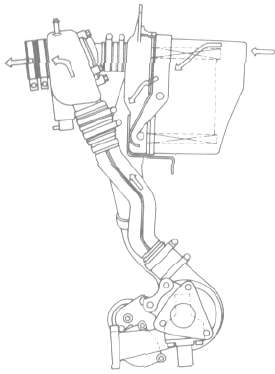

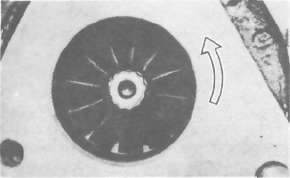

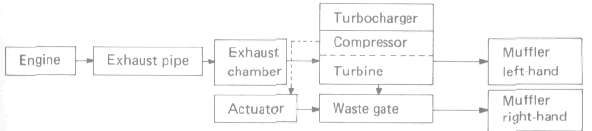

The turbo unit is pressure-lubricated from the main engine oil gallery. A check valve is installed on the outlet o' the engine main oil gallery to stop oil flow to the turbo unit when the engine is not running. A scavenging pump rotor is equipped behind the original oil pump rotor to retrieve the oil from the turbo unit, ensuring a constant flow of oil.

Check valve opening pressure: 24.5 kPa (0.25 kg/cm , 3.56 psi)

- Read more about Turbo Lubrication System

- Log in to post comments