Middle Gear

Middle GearMIDDLE GEAR/DAMPER

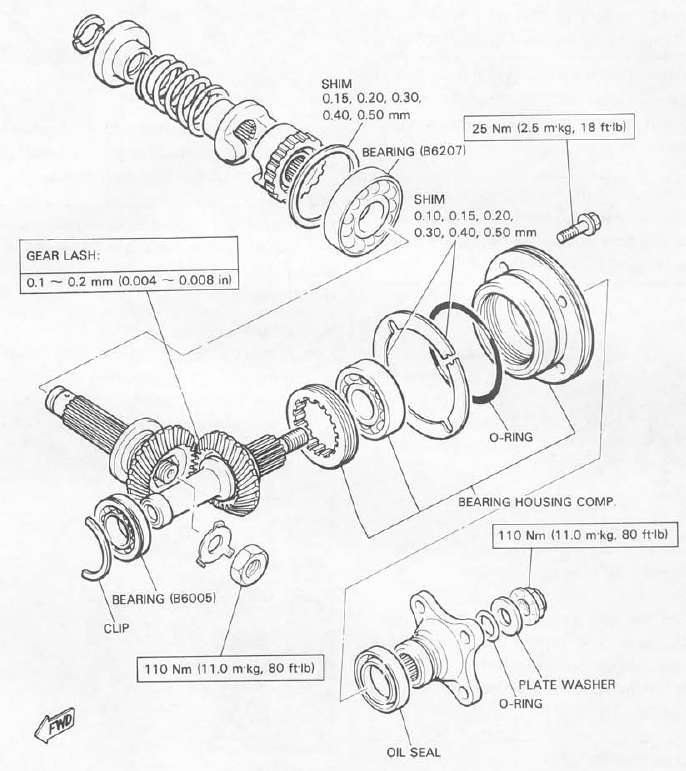

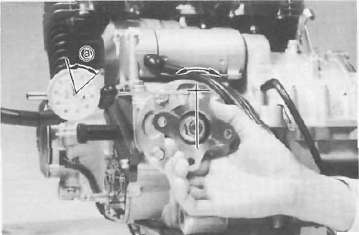

a. Middle gear lash 0 2 mm (0.008 in)

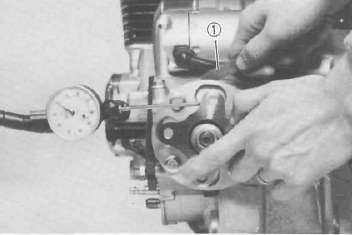

d. Measure the gap between the driven gear bearing housing flange and the crankcase with a feeler gauge. This is the shim size required.

1 Feeler gauge

e. Install the proper sized shims as shown and tighten the driven gear housing to the specified torque. Recheck the gear lash, it should be within the specification, if not readjust the shims.

Gear lash: 0.1 — 0.2 mm

(0.004 — 0.008 in)

1. Shims

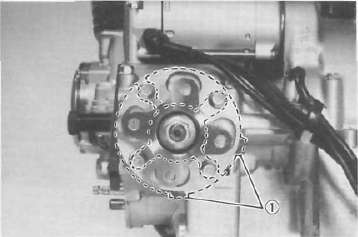

5. Drive gear positioning NOTE:

When the following part(s) is replaced with new one(s), drive gear positioning is necessary:

a. Crankcase

b. Middle gears

c. Middle gear bearing housing

a. The shim thickness necessary for the drive gear positioning can be calculated from the infomations found on the upper crankcase and on the drive gear end.

b. To fined shim thickness "A" use the formula:

A = c - a - b

Where:

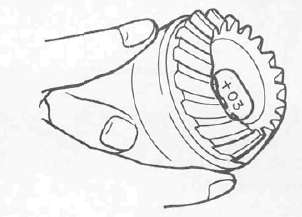

a = a numeral (usually a decimal number) printed on the shaft end as shown above and either added to or detracted from the nominal size "43".

b = a bearing thickness (considered constant)

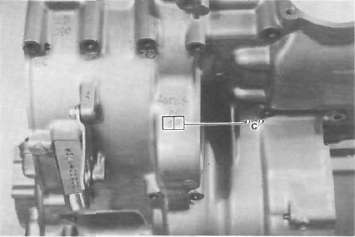

c = a numeral (usually a decimal number) found on the upper crankcase half near the main bearing selection numbers and added to the nominal size "60".

Distance "b" = 16.94 mm

Example:

1) If the shaft is marked +03....."a"

is 43.03 mm.

2) "b" is 16.94 mm.

3) If the crankcase is stamped "45" ....."c" is 60.45 mm.

A = c - a - b

A = 60.45 - 16.94 - 43.03

A = 0.48

Then the necessary shim thickness

is 0.48 mm. c. Shim size are supplied in the following thicknesses:

0.15 mm, 0.20 mm, 0.30 mm, 0.40 mm, and 0.50 mm.

Because the shims can only be selected in 0.05 mm increments the following chaft should be used when encountering last digits that are not 5 or zero(0):

|

Last digits |

Rounding |

|

0, 1,2 |

0 |

|

3, 4, 5, 6, 7 |

5 |

|

8,9 |

10 |

Shim 0.30 mm + 0.15 mm