XJ650LJ & LK (Turbo) Service Manual

XJ650LJ & LK (Turbo) Service ManualTABLE OF CONTENTS:

Chapter 1, Introduction

Chapter 1, Introduction

YAMAHA

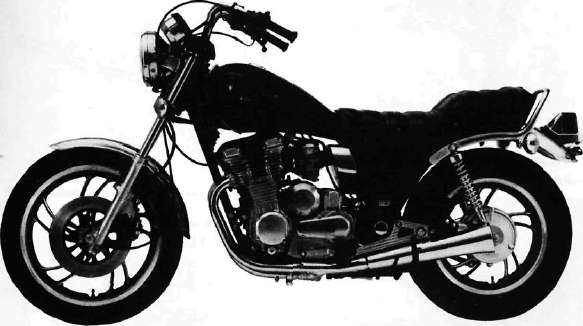

XJ650LJ and XJ650LK (Turbo)

NOTICE

This manual was written by the XJ Owners Group to replace the composite set of manuals and suppliments offered by Yamaha Motor Company primarily for use by Yamaha dealers and their qualified mechanics.

It is not possible to put an entire mechanic's education into one manual, so it is assumed that persons using this book to perform maintenance and repairs have a basic understanding of the mechanical concepts and procedures inherent to motorcycle repair technology. Without such knowledge, attempted repairs or service to this model may render it unfit to use and/or unsafe.

Particularly important information is distinguished in this manual by the following notations:

NOTE:

A NOTE provides key information to make procedures easier or clearer.

CAUTION:

A CAUTION indicates special procedures that must be followed to avoid damage to the motorcycle.

WARNING:

A WARNING indicates special procedures that must be followed to avoid injury to a motorcycle operator or person inspecting or repairing the motorcycle.

CHAPTER 1. GENERAL INFORMATION

MOTORCYCLE IDENTIFICATION

A. Frame Serial Number

The frame serial number is stamped into the right side of the steering head pipe.

B. Engine Serial Number

The engine serial number is stamped into the elevated part of the right rear section of the engine.

NOTE:

The first three digits of these numbers are for model identifications; the remaining digits are the unit production number.

SPECIAL TOOLS

The proper special tools are necessary for complete and accurate tune-up and assembly. Using the correct special tool will help to prevent damage from improper tools or improvised techniques.

A. For Tune-up

1. Compression gauge

2. Timing light

3. Tachometer

4. Tappet adjusting tool P/N. 90890-01245-00

This tool is necessary to replace valve adjusting pads. This can also be used for the XS750, XS850 and XS1100.

5. Vacuum gauge

P/N. TLU-11080-30-02

This gauge is needed for carburetor synchronization.

B. For Engine Service

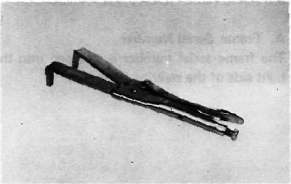

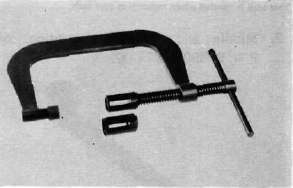

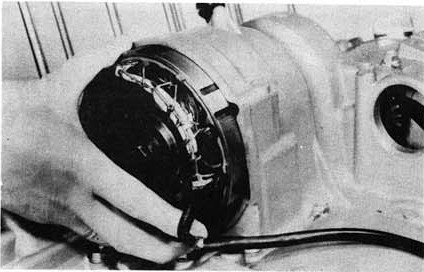

1. Clutch hub holder P/N. TLM-90910-42-00

This tool is used to hold the clutch when removing or installing the clutch boss lock nut.

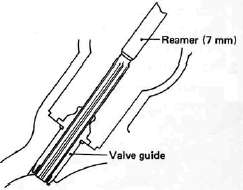

Valve guide reamer P/N. 90890-01227-00

This must be used when replacing the valve

guide

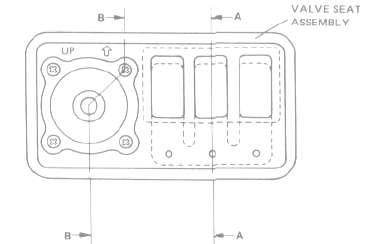

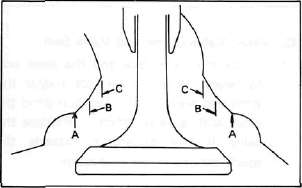

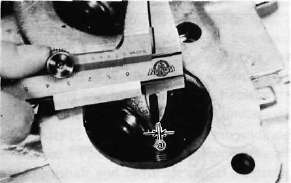

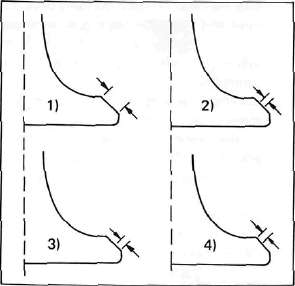

3. Valve seat cutter

P/N.TLM-90910-43-20

This tool is needed to re-surface the valve seat.

4. Valve guide remover P/N. 90890-01225-00

This must be used to remove the valve guides,

5. Valve guide installer P/N. 90890-04017-00

This tool is needed for proper installation of the valve guides.

6. Valve spring compressor P/N. 90890-01253-00

This tool must be used for removing and installing the valve assemblies.

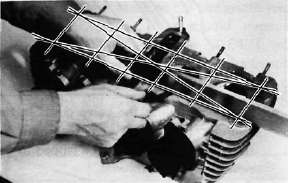

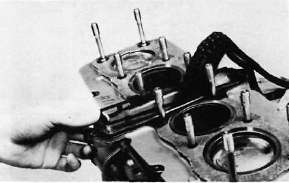

7. Piston ring compressor P/N. 90890-04044-00

This is used to compress piston rings when installing the cylinder.

8. Piston base

P/N. 90890-01067-00

Use 4 of these to hold the pistons during cylinder installation.

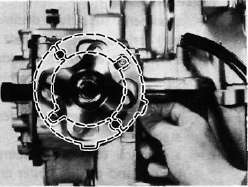

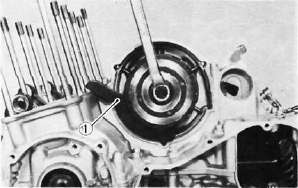

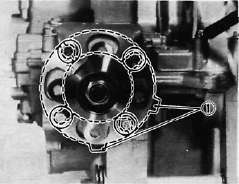

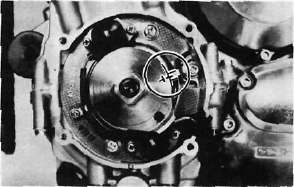

9. Rotor puller

P/N. 90890-01080-00

This tool is needed to remove the A.C. Generator rotor.

10. Rotor puller attachment P/N. 90890-04052-00

This tool is needed when removing the A.C. Generator rotor together with the rotor puller.

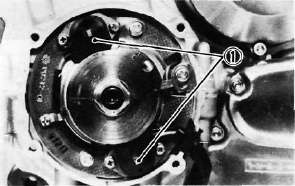

11. Rotor holding tool P/N. 90890-04043-00

This tool is used to hold the A.C. Generator rotor during removal and installation.

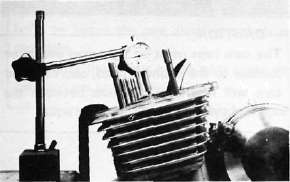

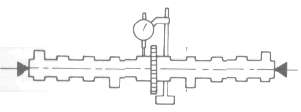

12. Dial gauge stand

P/N. 90890-01258-00

This tool is needed to hold the dial gauge.

13. Dial gauge

P/N. 90890-03097-00

This dial gauge is used to determine piston position for correct timing.

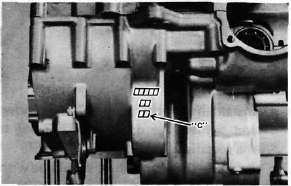

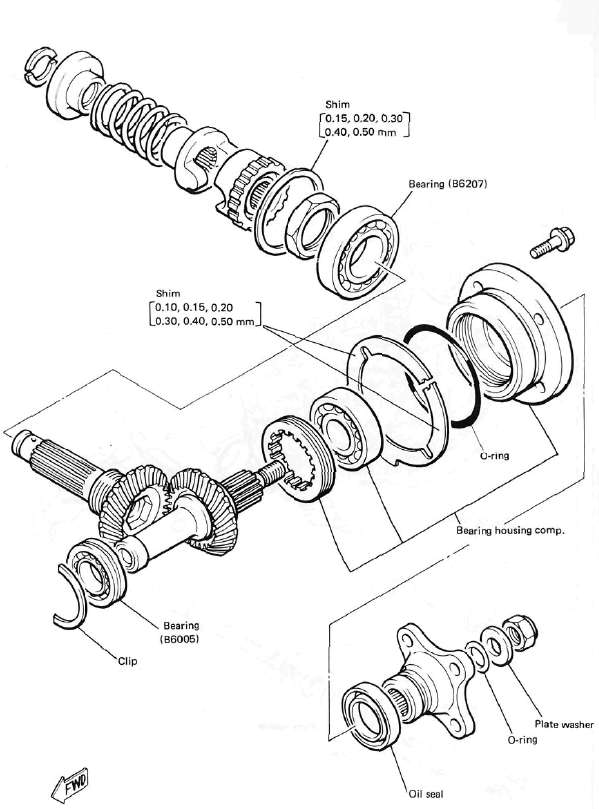

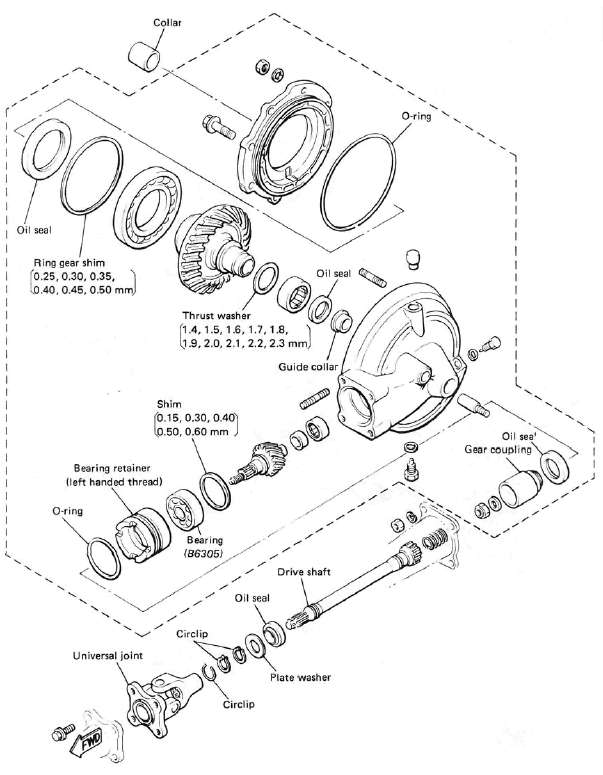

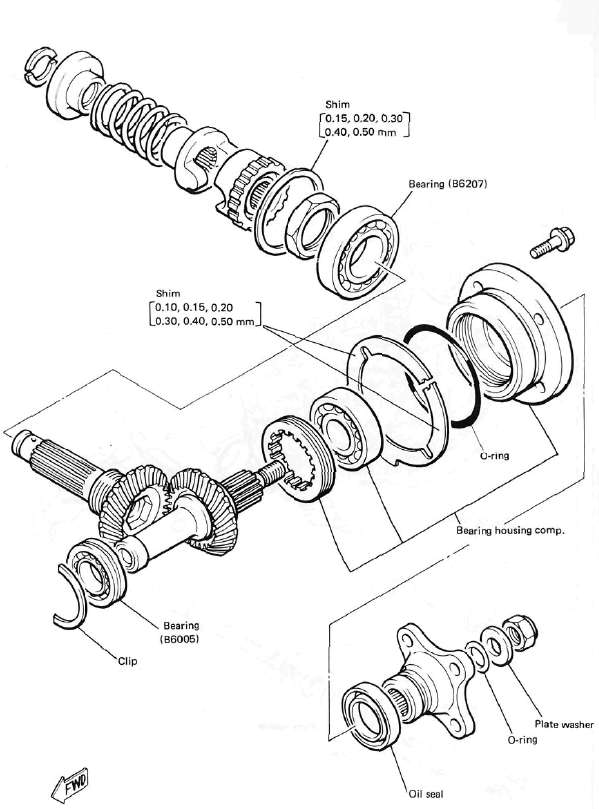

C. For Shaft Drive Service

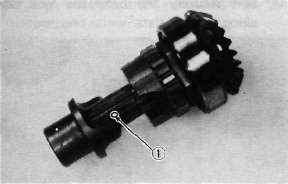

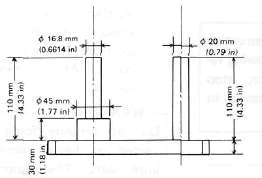

1. Middle drive pinion holder P/N. 90890-04051-00

This tool is needed when measuring gear lash.

2. Middle and final gear holding tool P/N. 90890-01229-00

This tool is needed when measuring gear lash.

3. Gear lash measurement tool (Final gear) P/N. 90890-01230-00

This tool is needed when measuring gear lash for final gear.

4. Final gear holding tool P/N. 90890-01254-00

This tool is needed when measuring gear lash.

5. Damper compressor P/N. 90890-04011-00

This tool is needed to disassemble and reassemble the middle gear damper.

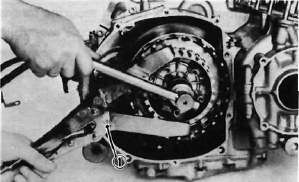

6. Middle drive shaft nut wrench P/N. 90890-04045-00

This tool is used to loosen and tighten the drive shaft nut,

7. Middle drive shaft holder P/N. 90890-04046-00

This tool is needed when loosening and tightening the drive shaft nut.

8. Drive pinion bearing retainer remover P/N. 90890-04050-00

This tool is used to loosen and tighten the final gear drive pinion bearing retainer.

9. Armature shock puller (M10 x 1.25) P/N. 90890-01290-00, 90890-01291-00

These tools are used to remove the final gear drive pinion.

10. Crank installer adapter (M10x1.25/M14x1.5) P/N. 90890-01277-00

This adapter is needed when using the armature shock puller.

11. Drive shaft puller P/N. 90890-04012-00

This tool is used to remove the drive shaft.

12. Slide hammer

P/N. 90890-01083-00, 90890-01084-00

These tools are used to remove the drive shaft.

13. Front fork cylinder comp. holder P/N. 90890-01300-00

This tool is used to loosen and tighten the front fork cylinder comp. holding bolt.

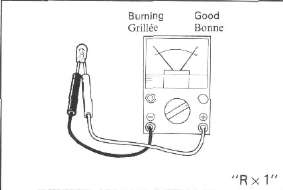

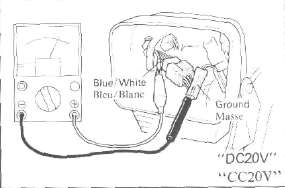

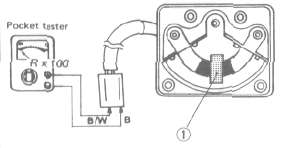

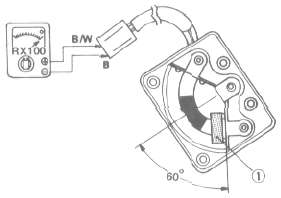

D. For Electrical Components

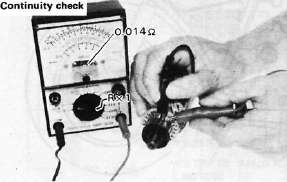

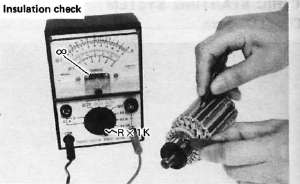

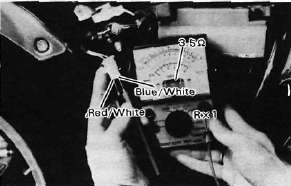

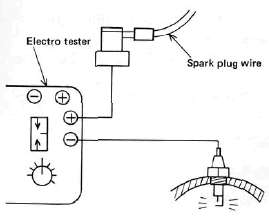

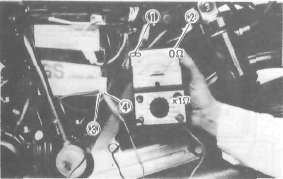

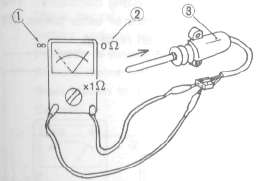

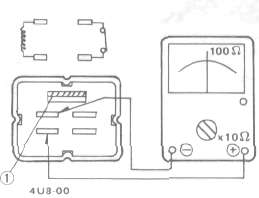

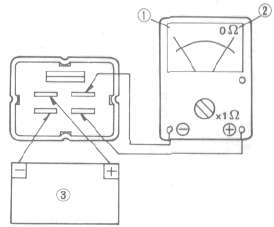

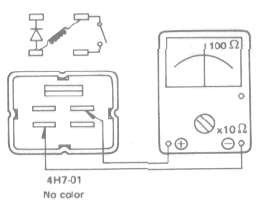

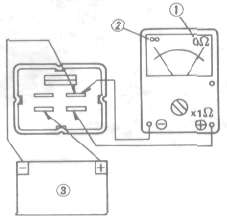

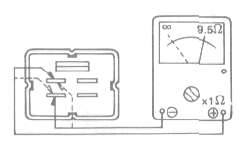

The uses of these tools are described in CHAPTER 6. 1. Pocket tester

P/N. 90890-03104-00

2. Electro tester

P/N. 90890-03021-00

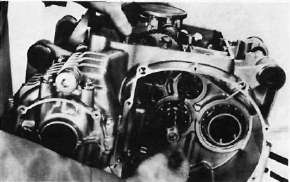

Special Features of the Turbo Models

Special Features of the Turbo ModelsMAJOR FEATURES

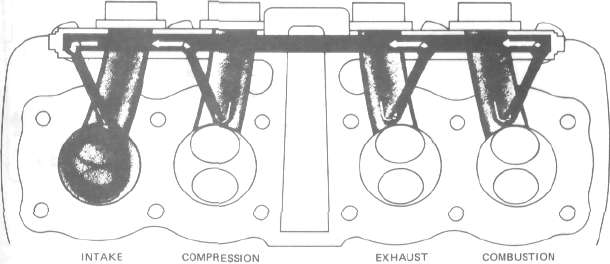

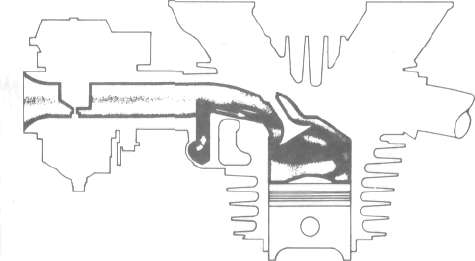

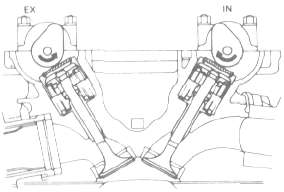

YAMAHA INDUCTION CONTROL SYSTEM

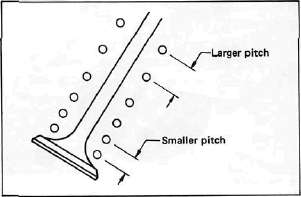

This system has subintake ports. The cross-section area of these subintake port is smaller than that of main intake ports. The smaller ports enter the main ports just above the intake valve seat and at such an angle that their charge is directed around the walls of the cylinder; this results in a swirling effect as the mixture is compressed into the combustion chamber.

The subintake ports for all four cylinders are interconnected. Since only one cylinder is on the intake stroke at a time, the subintake port for that cylinder draws mixture from the other three carburetors and subintake ports. When the piston is moving down and the intake valve opens, a vacuum is created in the main and subintake ports. But since the area of the subintake port is so much smaller, the mixture moves faster through it than through the main intake port. The charge from the subintake port, therefore, blasts around the wall of the cylinder, swirling the entire intake charge. This results in more complete burning of the air-fuel mixture.

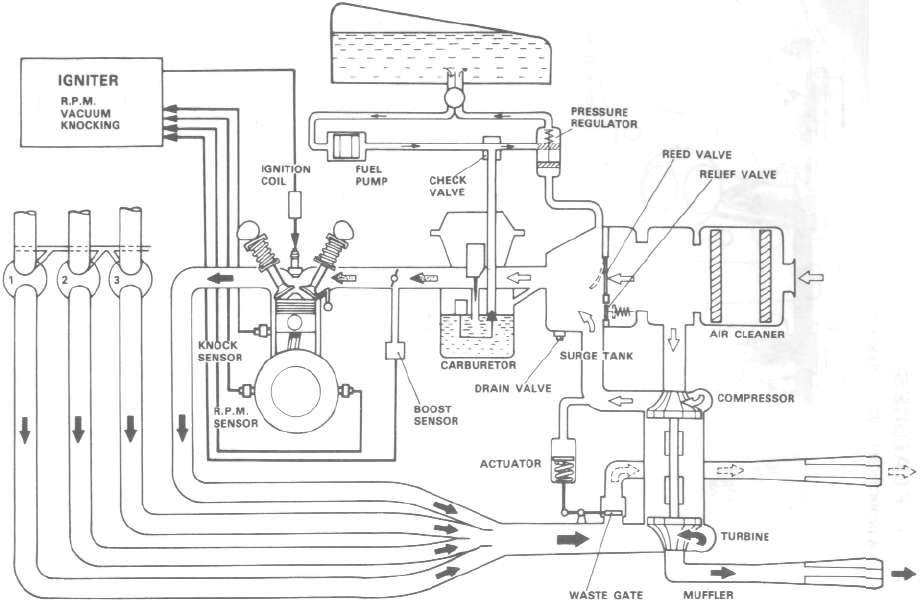

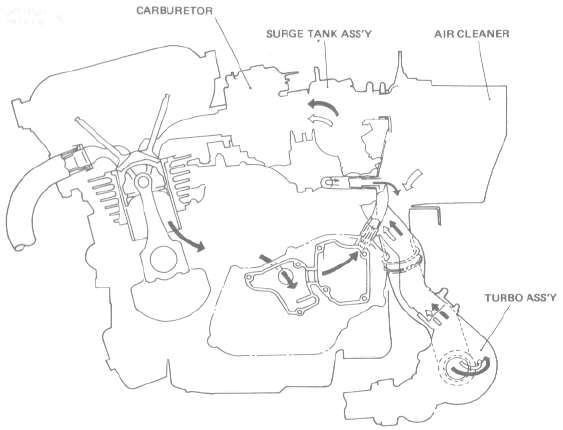

YAMAHA TURBO SYSTEM

GENERAL DESCRIPTION OF THE TURBOCHARGER

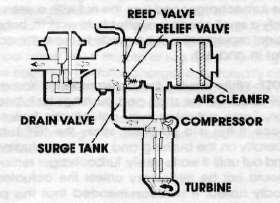

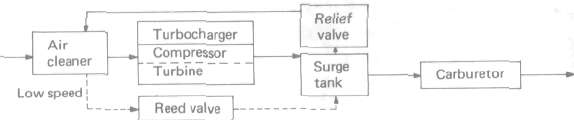

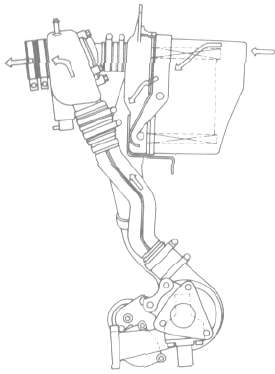

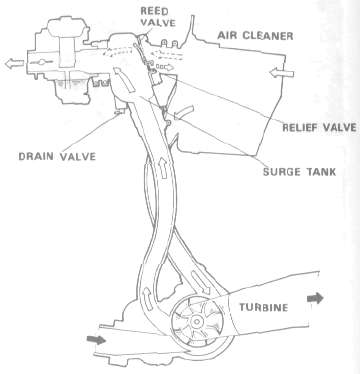

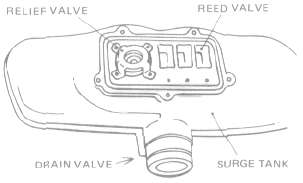

Yamaha has largely eliminated "turbo lag", a phenomenon which afflicts conventional turbo systems when the throttle is snapped open at low engine speeds. Since the turbo unit is spinning too slowly to provide an adequate air supply, a conventional turbo suffers a vacuum in the intake tract and hesitates before building speed. Yamaha's system, however, provides fresh air directly from the air cleaner to the surge tank through a reed-valve-controlled passage; the engine can build speed freely until the turbo unit resumes its pressurizing effect and closes the reed valve. Another notable feature in the surge tank is a poppet-type relief valve that backs up the wastegate in preventing excess boost in the intake side.

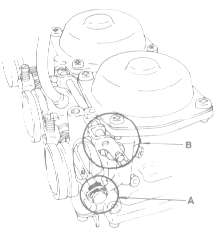

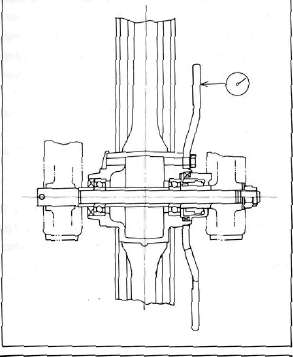

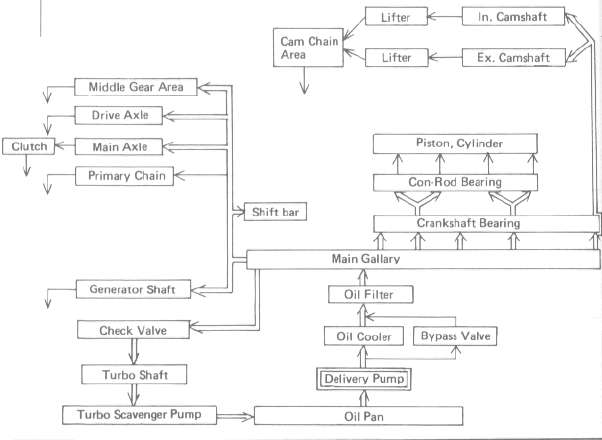

The turbocharger unit is subjected to exhaust temperatures of around 1500°F; it is therefore positioned behind the crankcase and below the swingarm pivot, well away from the rider and the fuel system. The turbo unit itself, a Mitsubishi TC03-O6A, is the world's smallest: the turbine diameter is only 39 mm, and it can spin safely up to 210,000 rpm. The shaft linking the turbine to the intake compressor is pressure-lubricated from the crankshaft's main oil gallery; an additional scavenging pump retrieves the oil from the turbo unit, ensuring a constant, adequate flow.

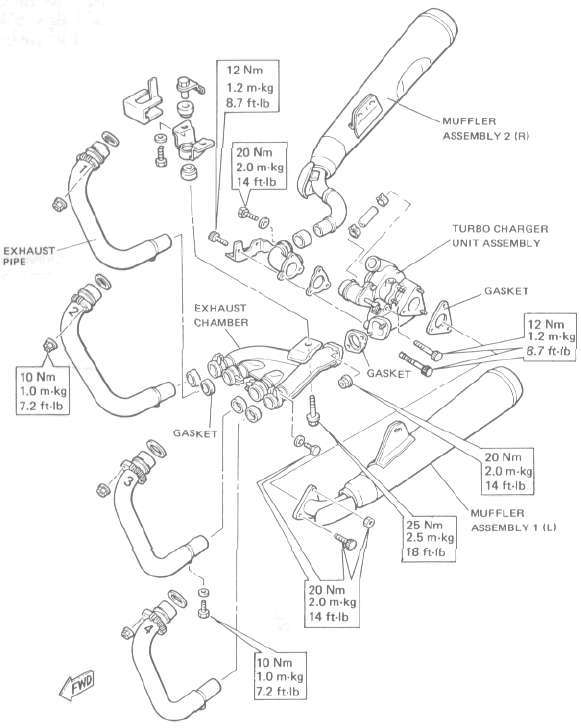

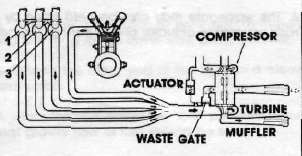

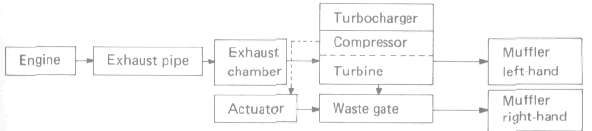

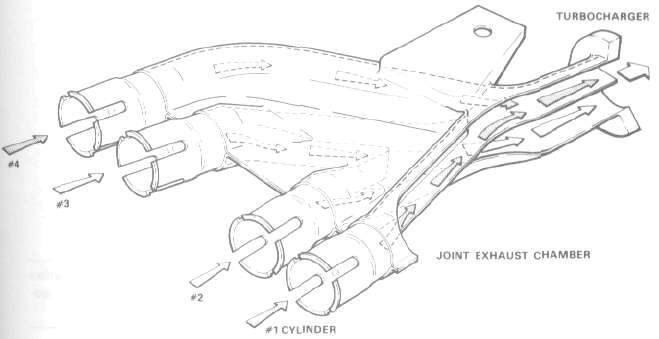

The exhaust system has an inner wall of stainless steel from the header pipes to the turbocharger. A patented exhaust manifold links the #1 and #4 exhaust pipes together and the #2 and #3 pipes together before they enter the turbocharger; this design provides even exhaust pulsing to drive the turbine and results in greater midrange torque. A wastegate in the manifold bleeds off excess exhaust pressure to prevent too much boost in the intake. The left-side muffler receives the exhaust gas from the turbo unit, and the right-side muffler handles excess from the wastegate.

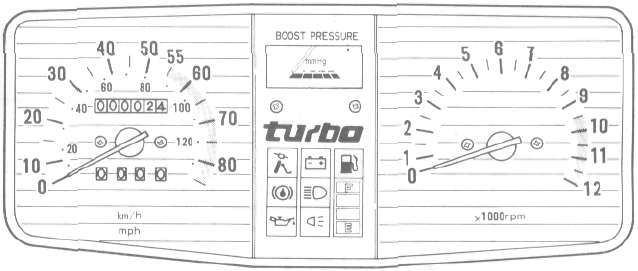

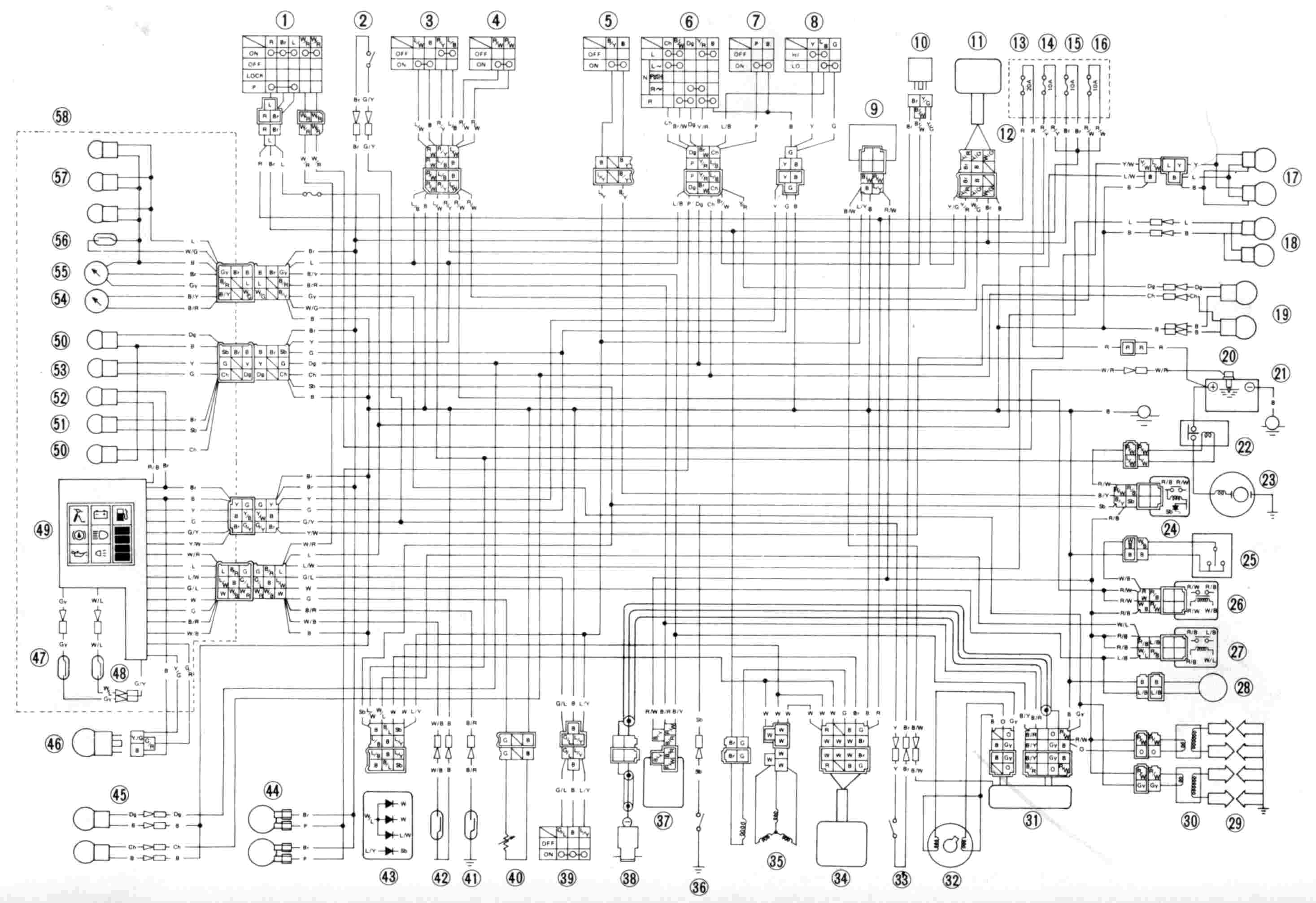

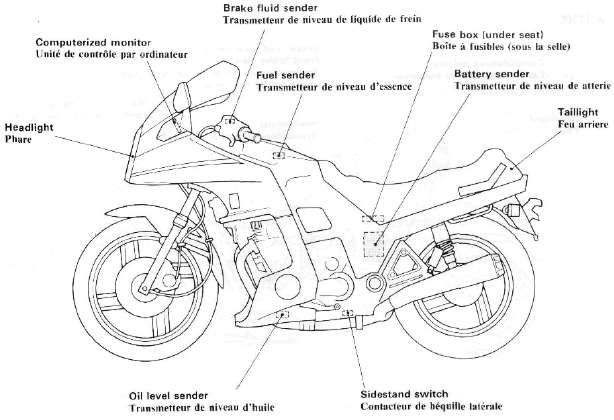

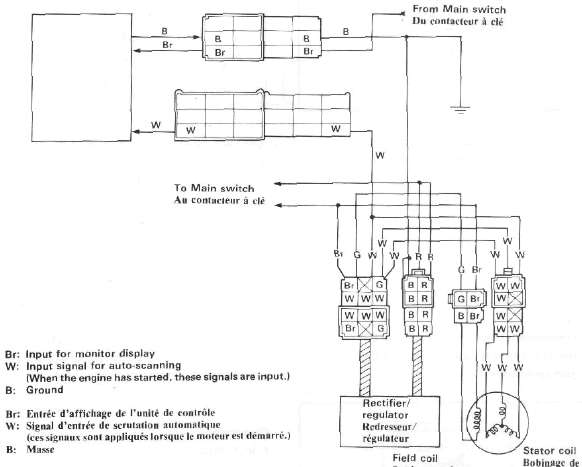

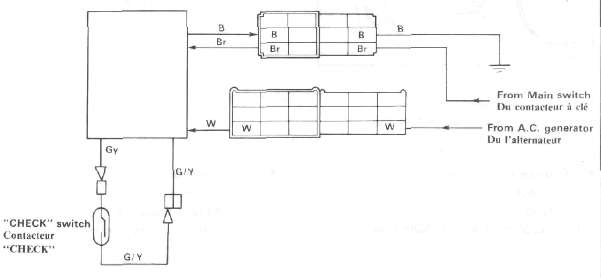

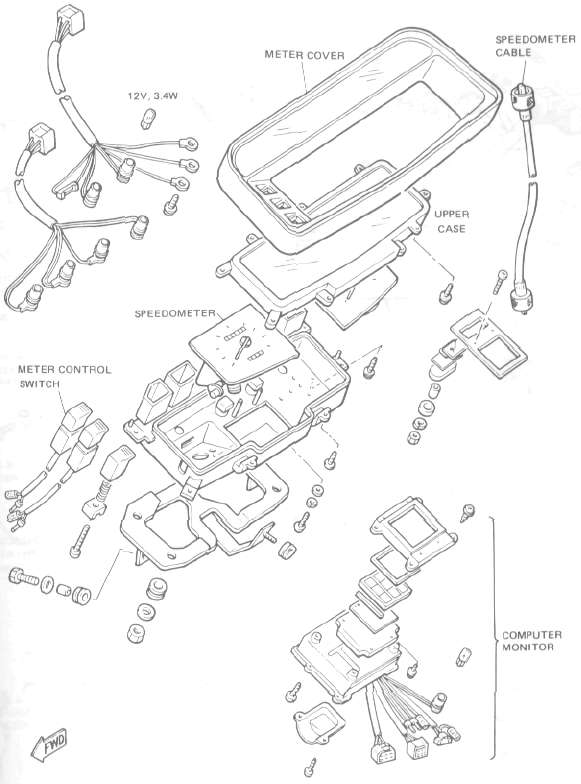

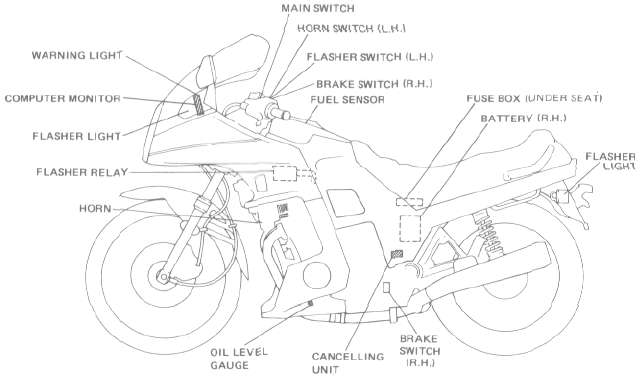

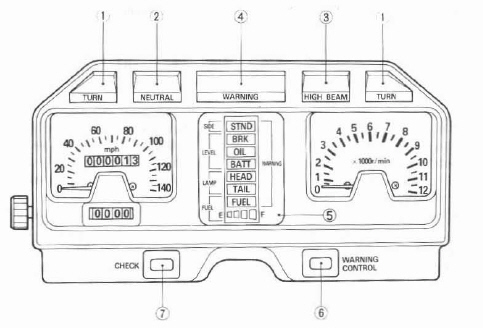

INSTRUMENT PANEL & PICTOGRAPHIC COMPUTER MONITOR SYSTEM

The XJ650 turbo computer monitor system features:

1. Easy-to-see pictographic displays; a further improvement upon the XJ750 computer monitor.

2. Highly reliable liquid crystal displays in three colors, specifically designed for motorcycle application.

1} Red display for safety

• Sidestand retraction

• Disc brake fluid amount

• Engine oil amount

• Fuel amount

2) Blue display for electrics

• Battery liquid amount

• Headlight

• Tail/brake light

3) Green display for remaining fuel amount

• Four-stage display for remaining fuel amount

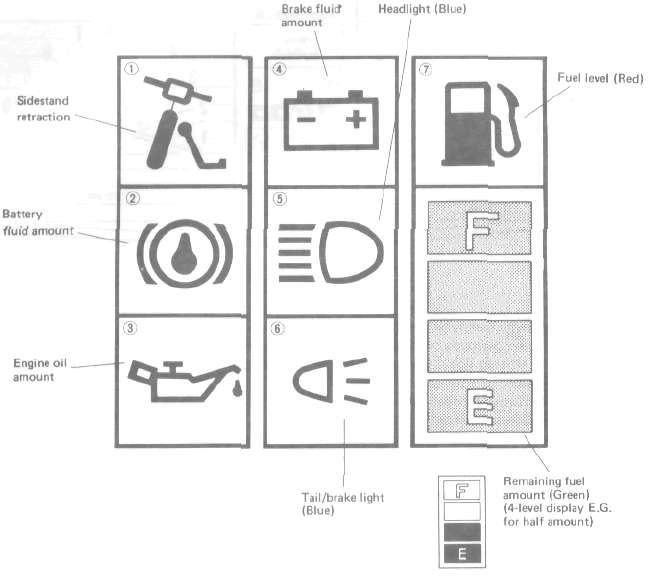

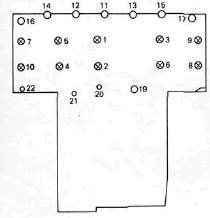

DISPLAY PANEL

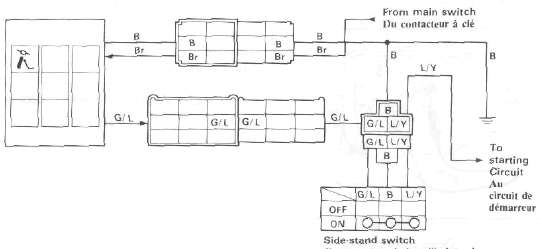

1 This indicator is displayed when the sidestand is not retracted.

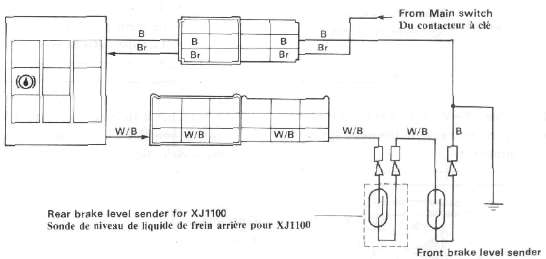

2 This indicator is displayed when the brake fluid level is below specification in the front brake master cylinder.

3 This indicator is displayed when the engine oil level is low.

4 This indicator is displayed when the battery fluid level is low.

5 This indicator is displayed when the headlight bulb is burned out.

6 This indicator is displayed when the taillight and/or brake light bulbs are burned out.

7 This indicator is displayed when the fuel level is low.

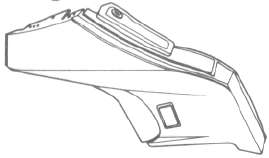

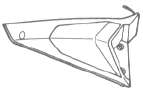

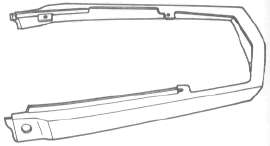

TURBO 650 FAIRING

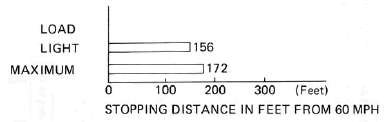

The fairings on Yamaha's innovative new models represent more than just handsome cosmetics. Indeed, from their inception to their final rendering, form was designated secondary to function. In designing a fairing; two of the most important aerodynamic factors are wind resistance and front wheel lift force. Through extensive wind-tunnel testing, Yamaha engineers crafted a fairing for the Seca Turbo which significantly reduces these effects. Every component down to the rear-view mirrors was designed with aerodynamic efficiency in mind. The coefficient of drag, a measurement of wind resistance, is among the lowest in the world for a road machine. A reduction of about 10% was achieved in front wheel lift force over a similar machine not equipped with a fairing.

Yamaha maintains its lead in advanced high-performance technology with the introduction of the XJ650LJ, featuring the Yamaha Turbo System. This system uses the power of the exhaust gases, normally wasted, to spin a turbine which supercharges the intake of the air fuel mixture. The system goes far beyond the unrefined, bolt-on turbochargers offered by accessory companies. The Yamaha Turbo System is a fully integrated combination of sophisticated engineering features which virtually eliminates the problems of conventional turbocharging while enhancing its advantages. The result is a lightweight, nimble-handling machine which performs like a superbike with an engine twice as large. Yamaha is proud to rewrite the books on high-performance motorcycling!

Chapter 2, PERIODIC MAINTENANCE

Chapter 2, PERIODIC MAINTENANCECHAPTER 2. PERIODIC INSPECTIONS AND ADJUSTMENTS

INTRODUCTION

This chapter includes all information necessary to perform recommend inspection

and adjustments. These preventative maintenance procedures, if followed, will

insure more reliable vehicle operation and a longer service life. The need for costly

overhaul work will be greatly reduced. This information applies not only to vehicles

already in service, but also to new vehicles that are being prepared for sale. Any

service technician performing preparation work should be familiar with this entire chapter.

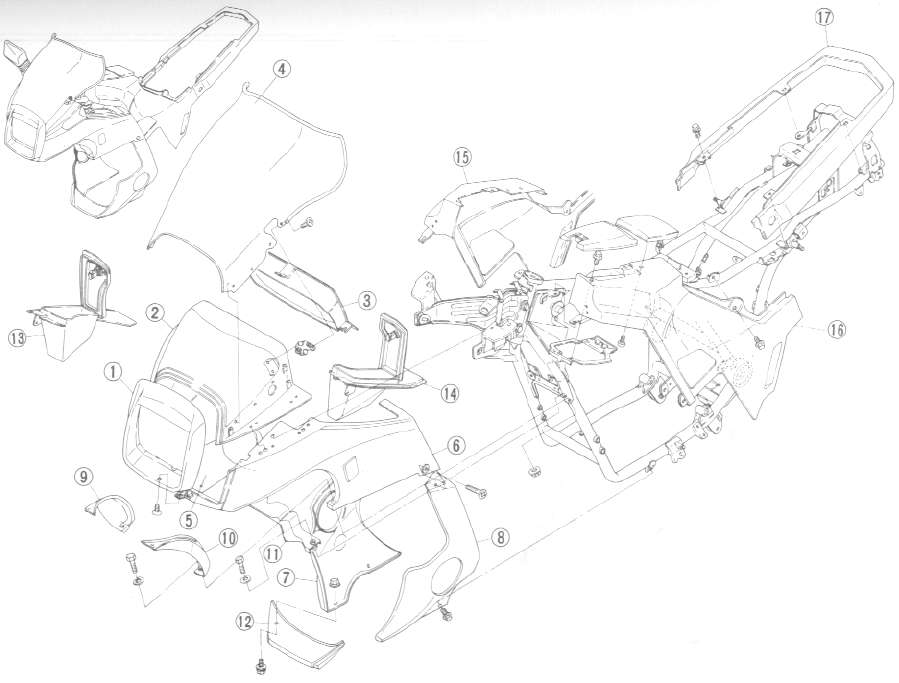

Fairing, Fuel Tank and Oil Cooler Removal

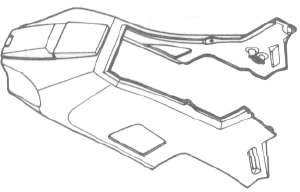

Fairing, Fuel Tank and Oil Cooler RemovalFAIRING REMOVAL

The fairing assembly must be removed to perform maintenance as well as major overhauling procedures. Some maintenance procedures require that only part of the fairing assembly be removed. Yamaha recommends, however, that the entire fairing assembly be removed whenever the motorcycle is serviced. This will ensure that the fairing is not damaged or unnecessarily marred.

The following table lists those fairing components that must be removed to gain access to a particular area or component:

|

|

Sections to be removed |

|

||||||||||

|

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

NOTE |

|

|

ENGINE |

A. Turbo Charger Unit |

|

|

|

o |

|

|

|

|

|

|

need not be removed, but servicing procedures will be much easier |

|

B. Valve Clearance Adjustment |

o |

o |

o |

|

o |

o |

o |

o |

o |

|

|

|

|

C. Ignition Timing |

|

|

|

o |

|

|

|

|

|

|

|

|

|

D. Air Cleaner |

o |

|

|

|

|

|

|

|

|

|

|

|

|

E. Carburetor |

o |

o |

o |

o |

|

|

|

|

|

|

|

|

|

F. Engine Oil |

o |

|

|

|

|

|

|

|

|

|

|

|

|

Q. Final Gear Oil |

|

|

|

|

|

|

|

|

|

|

|

|

|

H. Compression Pressure Measurement |

|

|

|

|

|

|

|

|

|

|

|

|

|

1. Clutch Adjustment |

|

|

|

|

|

|

|

|

|

|

|

|

|

CHASSIS |

A. Fuel Cock |

o |

o |

o* |

o* |

|

|

|

|

|

|

*Loosen the securing bolts |

|

B. Front and Rear Brake |

|

|

|

|

|

|

|

|

|

|

|

|

|

C. Tubeless Tires and Aluminium Wheels |

|

|

|

|

|

|

|

|

|

|

|

|

|

D. Front Fork Oil Change |

|

|

|

|

|

|

|

|

|

|

|

|

|

E. Rear Shock Absorber |

|

|

|

|

|

|

|

|

|

o |

|

|

|

F. Steering Head Adjustment |

|

|

|

|

|

|

|

|

|

o |

|

|

|

G. Cable Inspection and Lubrication |

o |

|

o |

|

|

|

|

|

|

|

Clutch cable inspection |

|

|

H. Throttle Cable and Grip Lubrication |

o |

|

o |

|

|

|

|

|

|

|

|

|

|

1. Rear Arm Pivot Bearings |

|

|

|

|

|

|

|

|

|

|

|

|

|

J. Brake and Change Pedals/Brake and Clutch Lever |

|

|

|

|

|

|

|

|

|

|

|

|

|

K. Center and Side Stand Pivots |

|

|

|

|

|

|

|

|

|

|

|

|

|

ELECTRICAL |

A. Battery |

o |

|

o |

|

|

|

|

|

|

|

|

|

B. Spark Plug |

|

|

|

|

|

|

|

|

|

|

|

|

|

C. Headlight |

|

|

|

|

|

|

|

|

o |

|

|

|

|

D. Fuse |

o |

|

|

|

|

|

|

|

|

|

|

|

1 SEAT

2 FUEL TANK

3 SIDE PANEL

4 LOWER PANEL

5 UPPER PANEL (Right)

6 UPPER PANEL (Left)

7 WINDSCREEN

8 HEADLIGHT NACELLE

9 FRONT FLASHER LIGHTS

10 REAR MOLDING

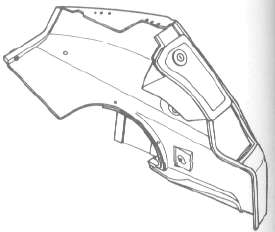

Fairing Removal

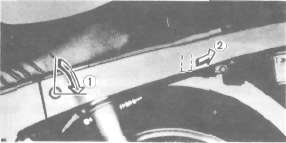

1. Remove the seat.

To open the seat lock, insert the key in the lock. Then, turn it clockwise and pull the lever backward.

1. Open 2. Pull

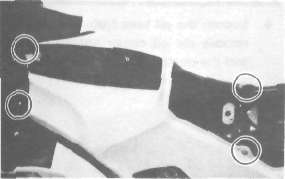

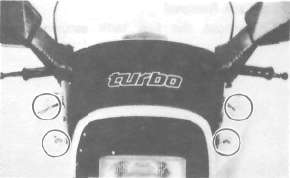

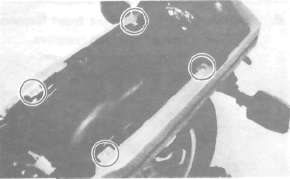

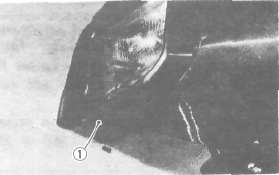

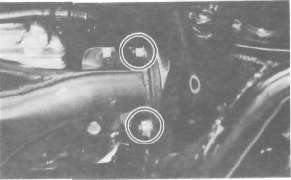

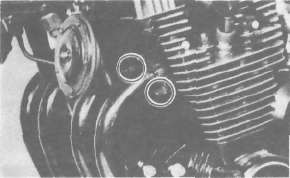

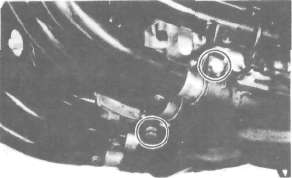

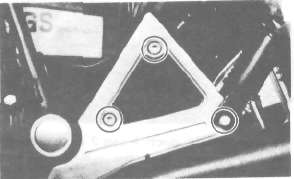

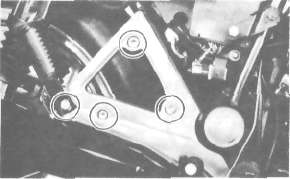

2. Remove the lower panel securing bolts (3X2) and remove the lower panel as one piece.

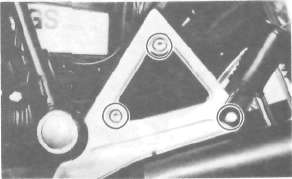

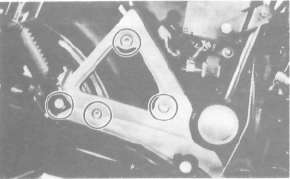

3. Remove the front securing bolts (2) and the side securing bolts (2).

4. Remove the side panels as one piece. Grasp the panels on either side where the panels are joined to the frame. Pull the male connectors out; then pull the rear of the panels up.

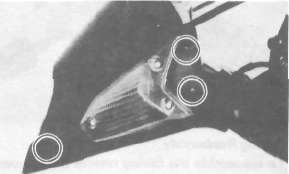

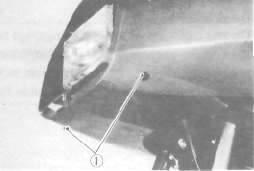

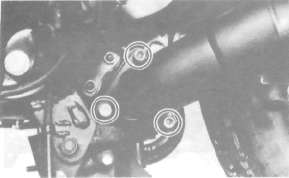

5. Remove the headlight nacelle.

6. Remove the left and right front flashers (3X2); disconnect the lead couplers.

7. Remove the windscreen with the rear view mirrors (2X2).

8. Remove the two clips.

9. Remove the left and right upper panels.

10. Remove the securing bolts (4) and remove the rear molding while prying the ends apart.

Fairing Reassembly

To reassemble the fairing reverse the removal procedure.

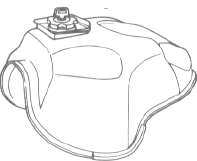

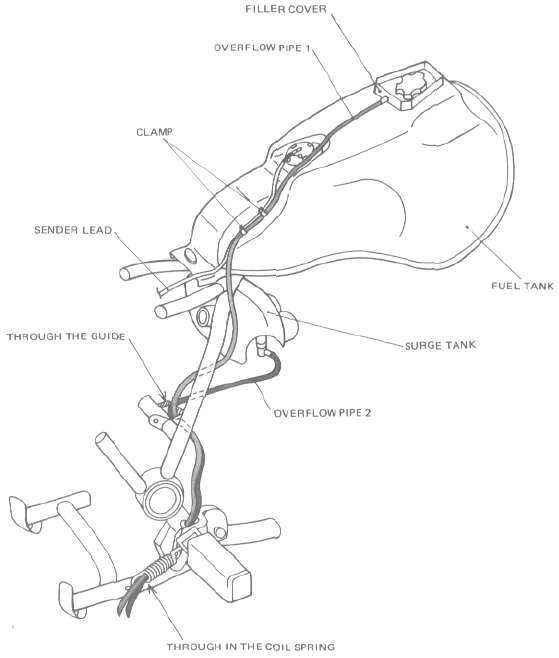

Fuel Tank Removal

1. Remove the fuel tank securing bolt.

2. Disconnect the overflow pipe and emergency engine stop switch lead connecter.

3. Disconnect the fuel lines.

4. Remove the fuel tank.

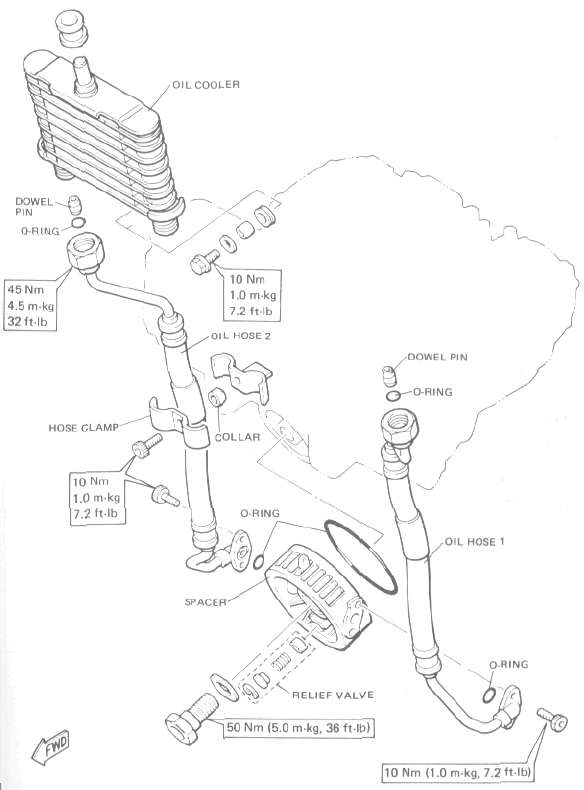

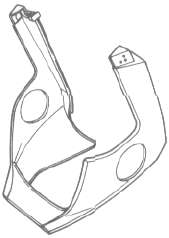

Oil Cooler Removal

1. Place an open container under the engine.

2. Remove the oil cleaner cap bolt.

3. Remove the spacer securing bolt.

4. Loosen the oil hose fitting nuts (2); then remove the oil cooler holding bolts (2) and the clamp bolt.

5. Remove the oil cooler assembly, pulling down and then away from the motorcycle.

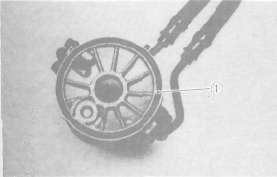

Oil Cooler Installation

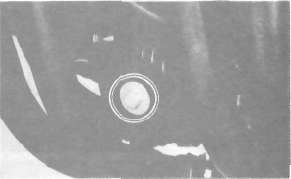

1. Install a new "O-ring" and install the oil cooler spacer to the crankcase. Make sure the "O-ring" is positioned properly.

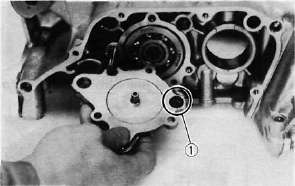

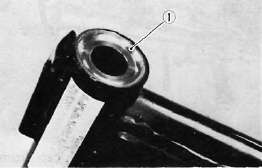

1.O-ring

2. Tighten the spacer securing bolt.

Tightening torque:

50 Nm (5.0m.kg, 36 ft-lb)

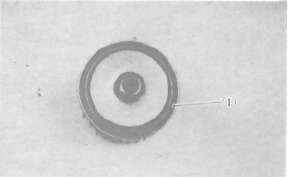

3. Install the oil filter element into the filter cover and install a new "O-ring". Make sure the "O-ring" is positioned properly.

1. O-ring

4. Tighten the oil cleaner cap bolt.

Tightening torque:

15 Nm (1.5 mkg, 11 ft-lb)

5. Tighten the oil cooler holding bolts (2).

Tightening torque:

10 Nm (1.0 m-kg, 7.2 ft-lb)

6. Tighten the clamp bolt.

Tightening torque: 10 Nm (1.0 m-kg, 7.2 ft-lb)

7. Tighten the oil hose fitting nuts (2).

Tightening torque: 45 Nm (4.5 m-kg, 32 ft-lb)

MAINTENANCE INTERVALS CHARTS

MAINTENANCE INTERVALS CHARTSProper periodic maintenance is important. Especially important are the maintenance services

related to emissions control. These controls not only function to ensure cleaner air but

are also vital to proper engine operation and maximum performance. In the following tables

of periodic maintenance, the services related to emissions control are grouped separately.

PERIODIC MAINTENANCE EMISSION CONTROL SYSTEM

|

NO. |

ITEM |

REMARKS |

INITIAL RREAK-IN |

THEREAFTER EVERY |

||

|

1.000 km |

5.000 km |

4.000 km |

8,000 km |

|||

|

1 |

Valve Clearance |

Check and adjust valve clearance when engine is cold. |

|

o |

|

o |

|

2 |

Spark plug |

Check condition. Adjust gap. Clean. |

|

o |

o |

Replace every |

|

3 |

Crankcase Ventilation |

Check ventilation hose 'or cracks or damage. |

|

o |

|

o |

|

4 |

Fuel Line |

Check fuel hose and vacuum pipe for cracks or damage. |

|

o |

|

o |

|

5 |

Intake/Exhaust System |

Check for leakage. Retighten as necessary. |

|

o |

o |

|

|

6 |

Idle Speed |

Check and adjust engine idle speed. |

|

o |

o |

|

| 7 |

Carburetor Synchronization |

Adjust synchronization of carburetors. |

|

o |

o |

|

GENERAL MAINTENANCE/LUBRICATION

|

NO'. |

ITEM |

REMARKS |

TYPE |

INITIAL BREAK-IN |

THEREAFTER EVERY |

|||

|

1,000 km |

5.000 km |

4,000 km |

8,000 km |

16.000 km |

||||

|

1 |

Engine Oil |

Warm up engine before draining |

Yamalube 4 cycle oil or SAE 2OW40 type SE motor oil |

o |

o |

o |

|

|

|

2 3 |

Oil Filter |

Replace |

— |

o |

o |

|

o |

|

|

Air Filter |

Clean with compressed air. |

- |

|

o |

|

o |

|

|

|

4 |

Brake System |

Adjust free play. Replace pads if necessary. (Front) Replace shoes if necessary (Rear) |

- |

o |

o |

o |

|

|

|

5 |

Clutch |

Adjust free play. |

- |

o |

o |

o |

|

|

|

6 |

Final Gear Oil |

Replace |

SAE 80 API "GL-4" Hypoid gear oil |

o |

|

|

o |

|

|

7 |

Control and Meter Cable |

Apply chain lube thoroughly. |

Y.irTidhj chain and cable lube or SAE 10W 30 motor oil |

o |

o |

o |

|

|

NOTE. 1. The air filter should be cleaned more often than at specified intervals if machine is operated in extremely dusty areas. 2- The lubrication chart must be adhered to strictly. Observe the following service hints to ensure that the oil will meet the demands placed on it by the engine.

Observe all periodic inspections as outlined. Use only the oil grade* specified. Keep the oil level at the specified level.

|

NO |

ITEM |

REMARKS |

TYPE |

INITIAL BREAK-IN |

THEREAFTER EVERY |

|||

|

1,000 km |

5.000 km |

4.000 km |

8.000 km |

16,000 km |

||||

|

8. |

Rear Arm Pivot Bearing |

Check bearings assembly for looseness. |

Medium weight bearing grease. |

|

|

|

|

Repack |

|

9 |

Centre- and Side- stand Pivots |

Apply lightly |

Yamaha chain and cable lube |

|

O |

o |

|

|

|

10. |

Front Fork Oil |

Drain completely. Refill to specification |

Yamaha fork oil 10 wt or equivalent |

|

|

|

|

O |

| 11, |

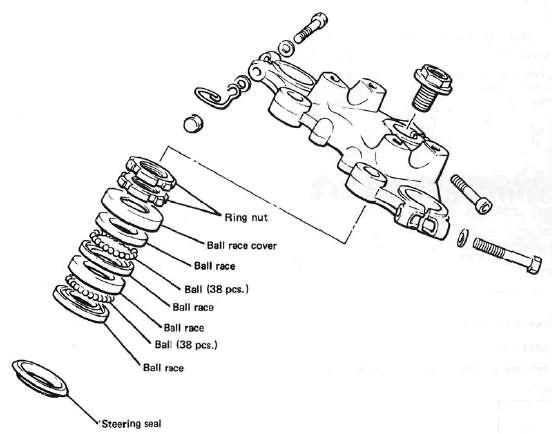

Steering Ball Bearing and Race* |

Check bearings assembly for looseness. |

Medium weight wheel bearing grease |

|

O |

o |

|

Repack |

|

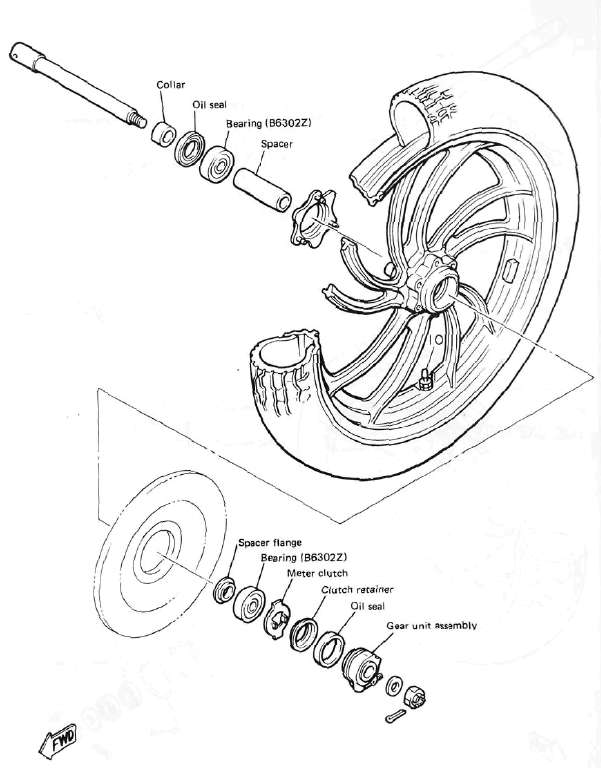

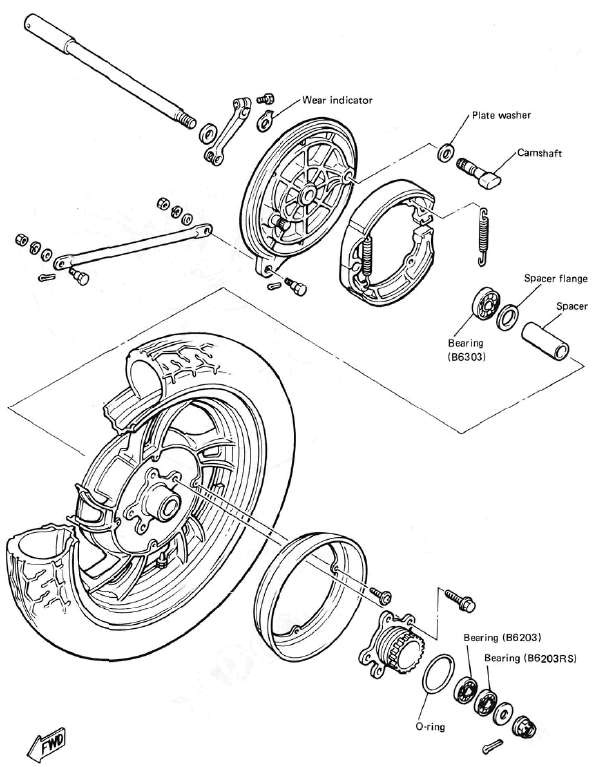

12. |

Wheel Bearings |

Check bearings for smooth rotation. |

- |

|

O |

o |

|

|

|

13. |

Battery |

Check specific gravity. |

- |

|

O |

o |

|

|

|

14. |

Change/ Brake Pedal shaft Pivot |

Apply lightly |

Yamaha chain and cable lube |

|

O |

o |

|

|

|

15. |

AC Generator |

Replace generator brushes. |

- |

|

|

|

|

Replace |

|

16. |

Apply lightly |

Apply lightly |

Yamaha chain and cable lube |

|

o |

o |

|

|

Engine Maintenance

Engine MaintenanceENGINE

A. Valve clearance adjustment

NOTE:

Valve clearance must be measured with the engine and at room temperature.

1. Remove the seat, fairing components, and fuel tank. See page 35.

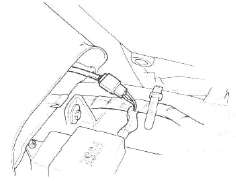

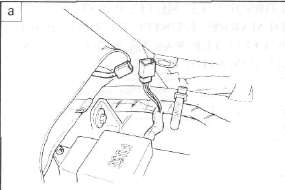

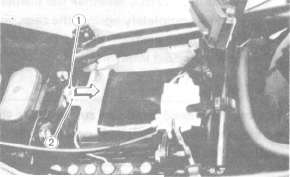

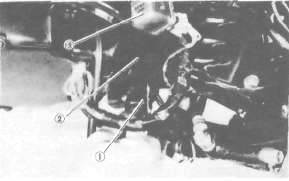

2. Remove the horn, flasher relay, emergency engine stop relay and spark plug lead wires.

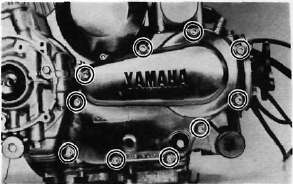

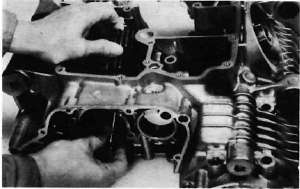

3. Remove the cylinder head cover and left crankcase cover (pick-up base cover). Care should be taken to not scratch or damage the gasket sealing surfaces.

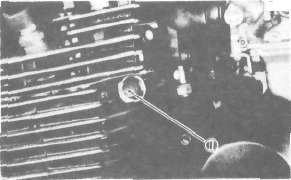

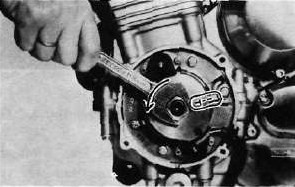

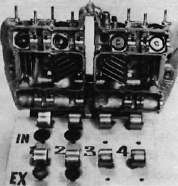

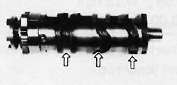

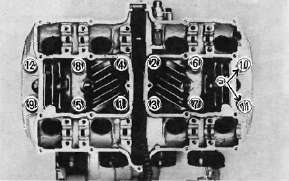

4. Turn the crankshaft with the nut on the left end of the crankshaft to turn the cams. The proper position of the cam when measuring the valve clearance is with the cam lobe directly opposite the valve lifter.

5. Insert a feeler gauge between the valve lifter and the camshaft base circle,

Intake valve clearance (cold): 0.11-0.15 mm (0.004- 0.006 in)

Exhaust valve clearance (cold): 0.16-0.20 mm (0.006- 0.008 in)

Adjustment

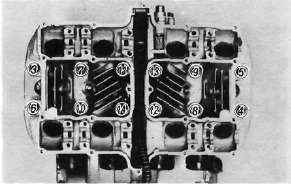

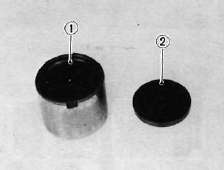

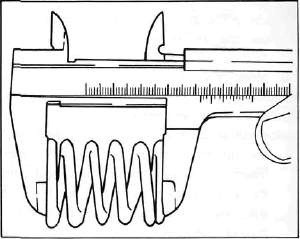

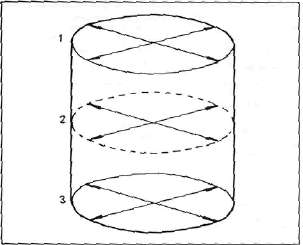

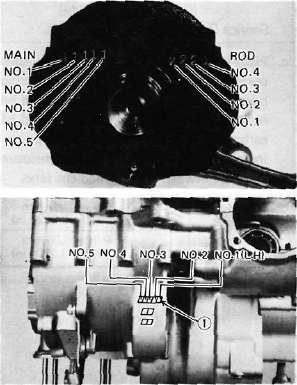

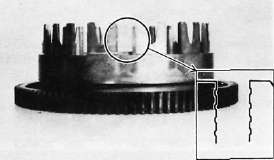

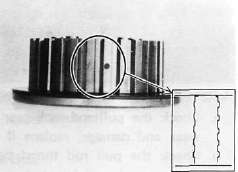

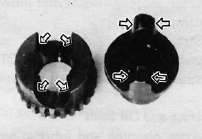

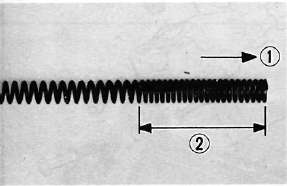

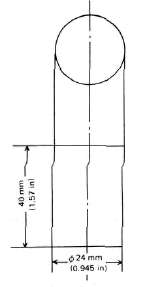

Valve clearance is adjusted by replacing the adjusting pad on the top of the valve lifter. Adjusting pads are available in 25 thicknesses ranging from No. 200 (2.000 mm) to No. 320 (3.20 mm) in steps of 0.05 mm. The thickness of each pad is marked on the pad face that contacts of the valve lifter (not the cam). Adjustment of the valve clearance is accomplished as follows:

1. Determine valve clearance (feeler gauge measurement.)

2. Remove adjusting pad and note number.

3. Select proper pad from appropriate chart (intake or exhaust chart).

4. Install new pad and check installed clearance.

Procedure

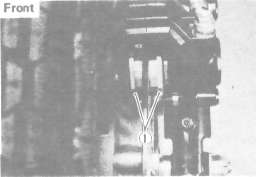

1. Measure valve clearance. If clearance is incorrect, record the measured amount of clearance. This must be measured carefully.

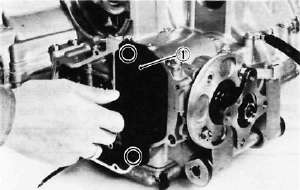

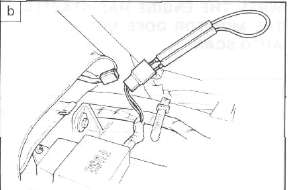

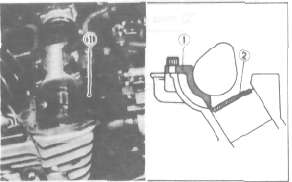

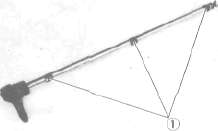

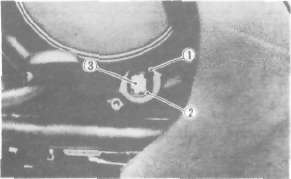

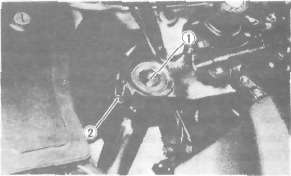

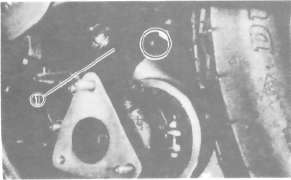

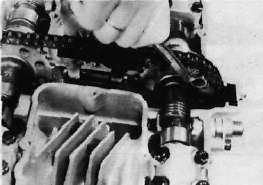

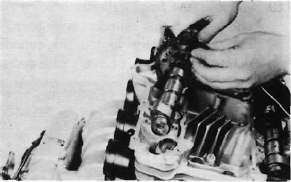

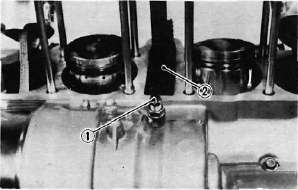

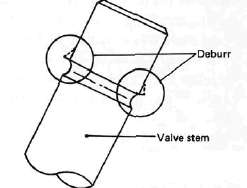

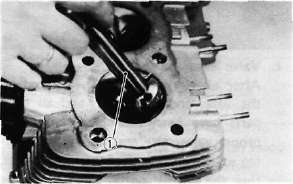

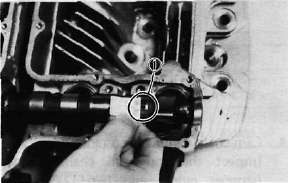

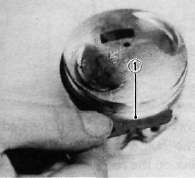

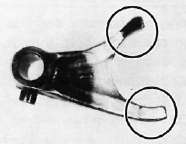

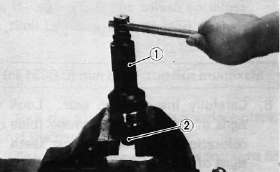

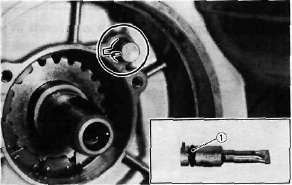

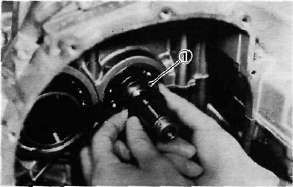

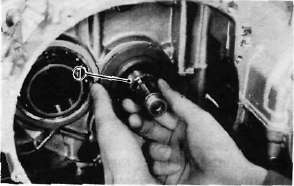

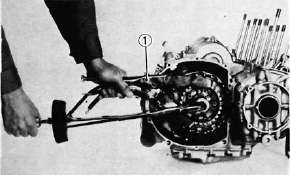

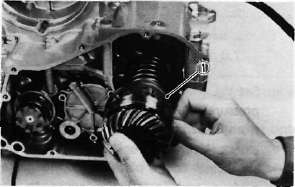

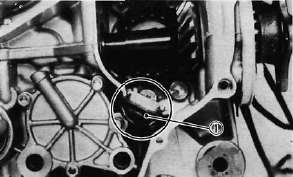

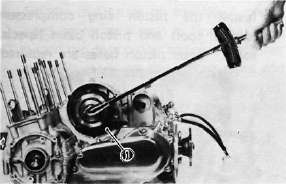

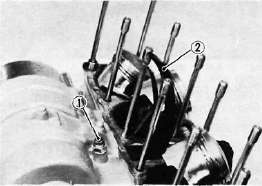

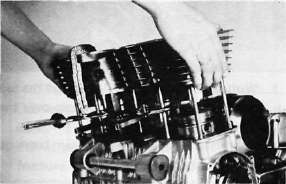

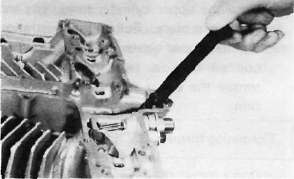

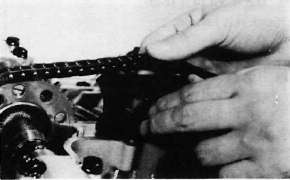

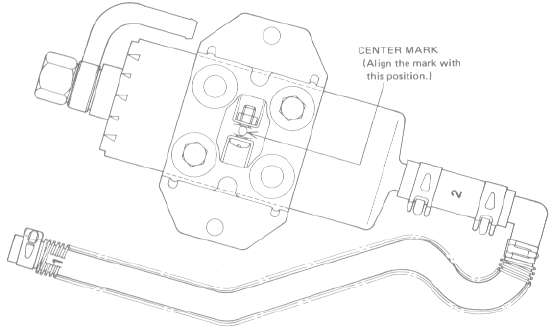

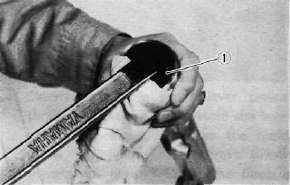

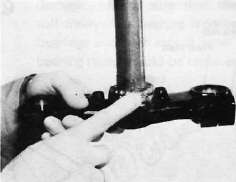

2. There is a slot in the valve lifter. This slot must be positioned opposite the blades of the tappet adjusting tool before the tools is installed.

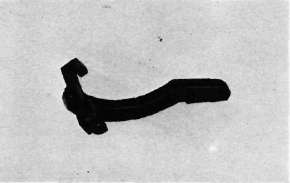

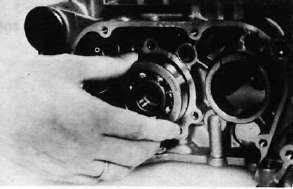

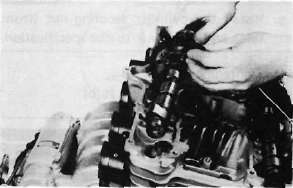

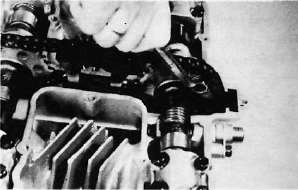

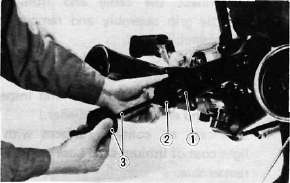

3. Turn the cam until the lobe fully depresses the valve lifter and opens the valve. Install the tappet adjusting tool as shown to hold the lifter in this depressed position.

NOTE:

The tappet adjusting tool is fastened to the cylinder head securely using one alien screw such as one used to install the cylinder head cover. Make sure that the tool contacts the lifter only, and not the pad.

CAUTION:

If the cam lobe touches the tappet adjusting tool, the stress may fracture the cylinder head. DO NOT ALLOW THE CAM TO CONTACT THE TAPPET ADJUSTING TOOL.

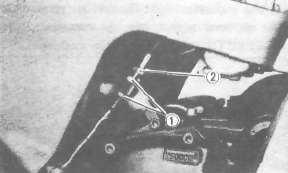

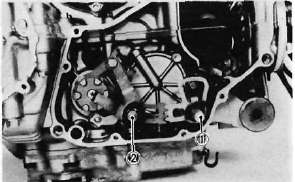

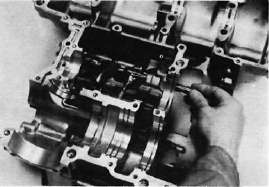

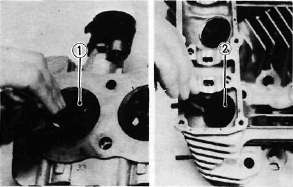

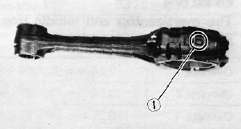

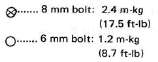

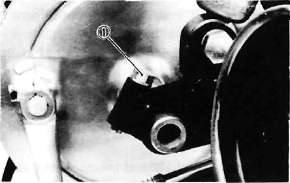

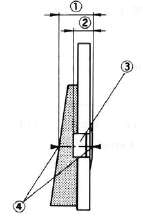

1 tappet adjusting tool 2. Adjusting pad

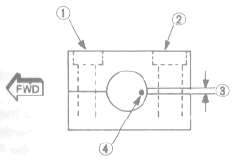

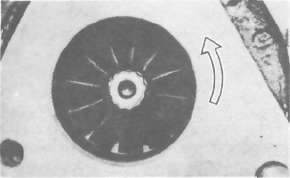

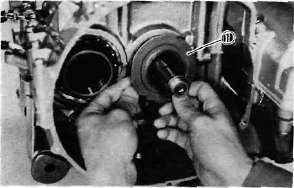

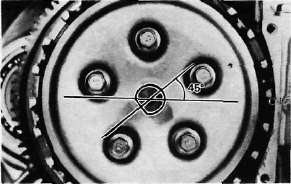

4. Carefully rotate the cam so that the pad can be removed. To avoid cam touching the adjusting tool, turn cams as follows: (view from left side of the motorcycle)

Intake: Carefully rotate CLOCKWISE.

Exhaust: Carefully rotate COUNTERCLOCKWISE.

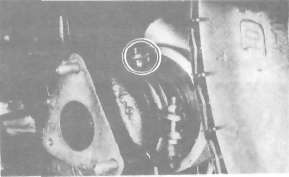

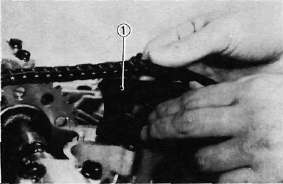

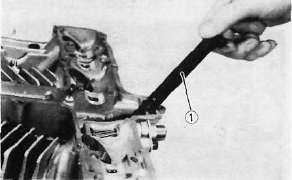

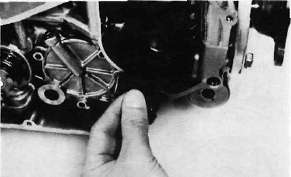

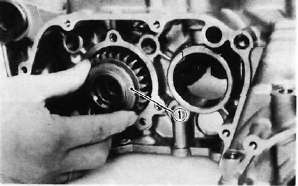

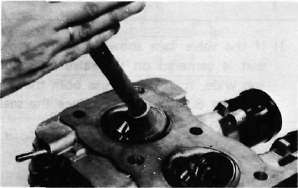

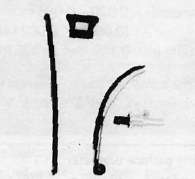

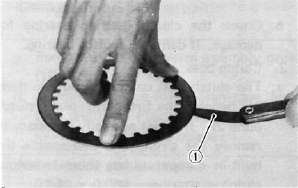

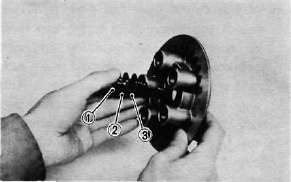

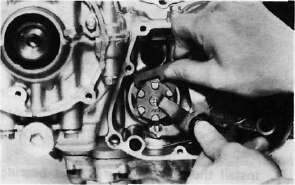

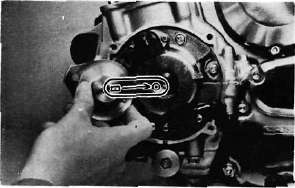

5. Remove the pad from the lifter. There is a slot in the lifter. Use a smaller screwdriver or other blade and a magnetic rod to remove the pad. Note the number on the pad.

1. Adjusting pad

6 Proper pad selection is made as follows:

Chart lookup method:

(Use appropriate chart for exhaust or intake valves, attached to this page, below.)

a. Find number of original (installed) pad number on chart. Read down on chart.

b. Find measured valve clearance (from step 1) on chart. Read across.

c. At the intersection of installed pad number (down) and measured clearance (across) is a new pad number.

I EXAMPLE:

Intake valve, installed pad:

No. 250 (read down) Measured clearance:

0.32 mm (read across) New pad number: No. 270

(intersection of down & across)

NOTE: The new pad number is to be used as a guide only. Verify the correctness of this choice in the following step(s).

7. Install the new pad in the lifter. Install the pad with the number down.

8. Remove tappet adjusting tool,

9. Turn crankshaft to rotate cam several rotations. This will set the pad in the lifter.

10. Check valve clearance (step 3). If clearance is incorrect, repeat preceding steps until proper clearance is obtained.

11. Inspect head cover gasket. If bent or torn, replace gasket.

12. Reinstall removed parts in reverse order.

Alternate shim calculation method:

NOTE:

This is not a Yamaha procedure. This was developed by the XJ Owners' Group.

Since all shims come in .05mm (.002") increments, you can quickly calculate the required size without a chart.

If the measured clearance is within 0.05mm (0.002") of the required clearance, then no change is needed.

If the measured clearance greater than 0.05mm (0.002") but 0.10mm (0.004") or less different than the required clearance then the next size shim is required.

If the measured clearance greater than 0.10mm (0.004") but 0.15mm (0.006") or less different than the required clearance then the next size shim is required.

Clearances that are too small require thinner shims. Clearances that are too large require thicker shims.

Example: Required exhaust valve clearance is 0.16~0.20mm. Measured clearance is 0.12mm (gap too small). Installed shim is Y270. Required shim is one size thinner: Y265.

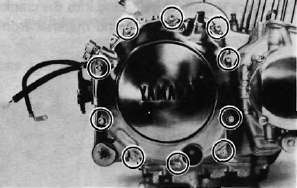

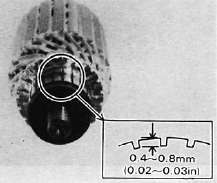

B. Spark plug

1. Check the electrode condition and wear, insulator color, and electrode gap,

2. Use a wire gauge for measuring the plug gap.

3. If the electrodes become too worn, replace the spark plug.

4. When installing the plug, always clean the gasket surface. Wipe off any grime that might be present on the surface of the spark plug, and torque the spark plug properly.

Standard spark plug:

BPR8ES(NGK) or W24EPR-U (ND) Spark plug gap:

0.7 ~ 0.8 mm (0.028-0.032 in) Spark plug tightening torque:

2.0 m-kg, (14.5 ft-lb)

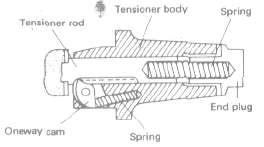

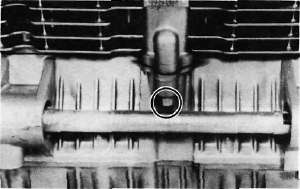

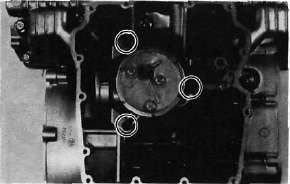

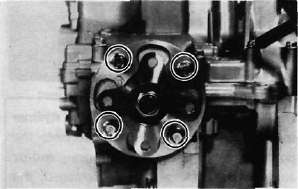

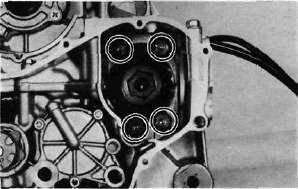

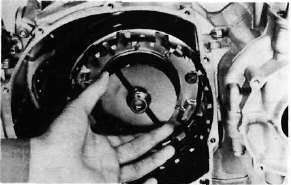

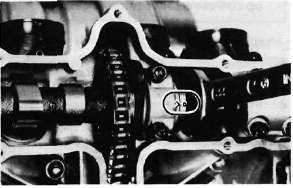

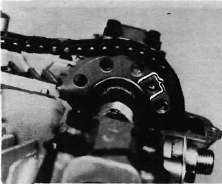

C. Cam chain tensioner

This model has been equipped the automatic cam chain tensioner. No adjustment is necessary.

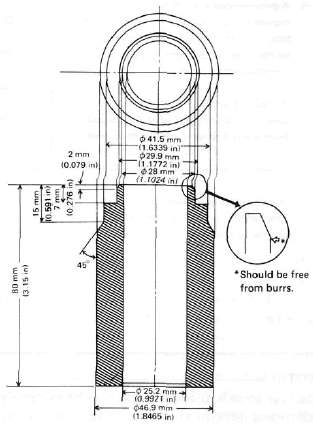

When installing this tensioner onto the cylinder, proceed as follows:

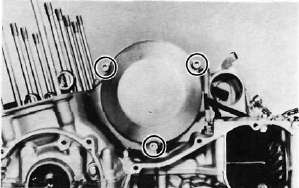

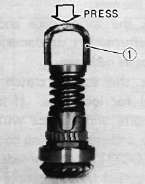

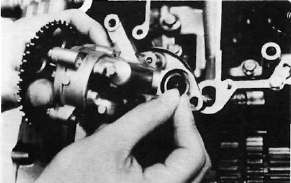

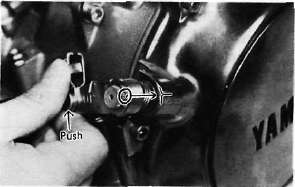

1. Remove the end plug and spring from the tensioner assembly.

2. Unlock the one-way cam by pushing it with your finger and push the tensioner rod into the tensioner body until it stops.

3. Install the tensioner to the cylinder and torque the bolts to the specification.

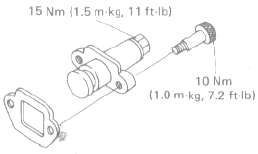

Tightening torque:

10 Nm (1.0 m-kg, 7.2 ft-lb)

4. Reinstall the spring and end plug with the gasket. Torque the end plug to the specification.

Tightening torque:

15 Nm (1.5 m-kg, 11 ft-lb)

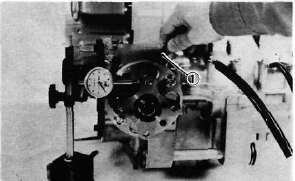

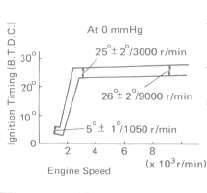

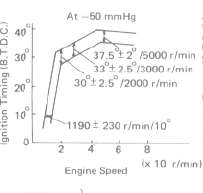

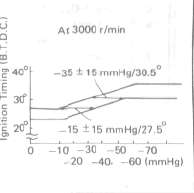

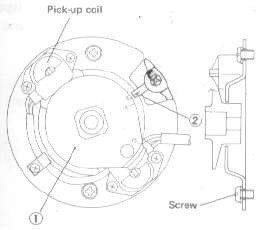

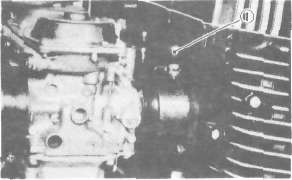

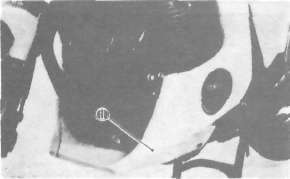

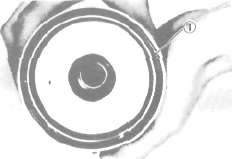

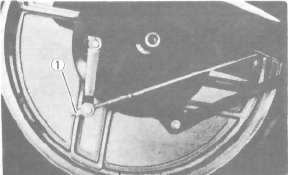

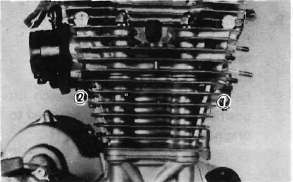

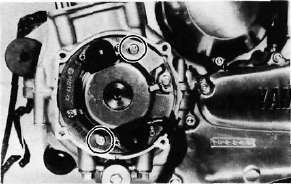

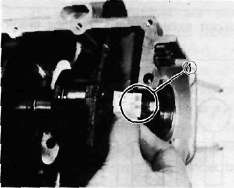

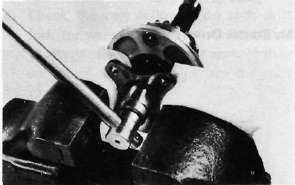

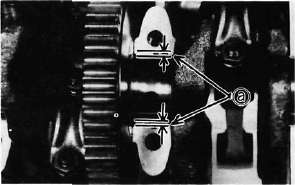

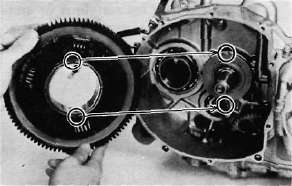

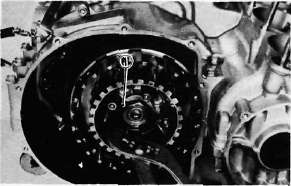

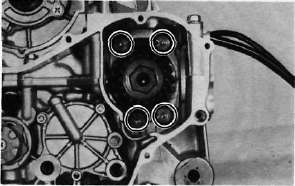

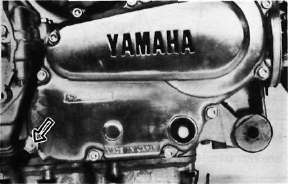

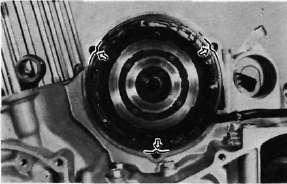

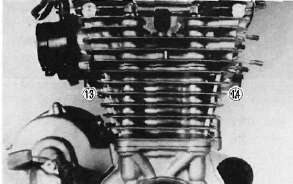

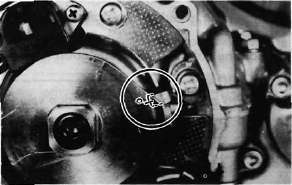

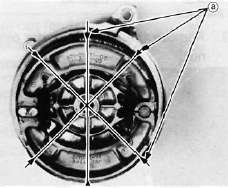

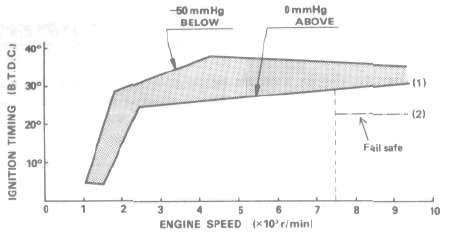

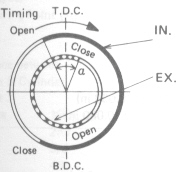

D, Ignition timing 1. Ignition timing is checked with a timing light by observing the position of the stationary pointer and the marks stamped on the timing plate.

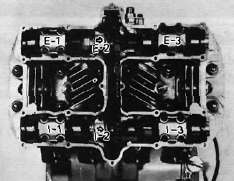

The timing plate is marked as follows:

.... Firing range for No. 1 (L.H.) cylinder

.... Firing range for No. 1 (L.H.) cylinder

... Top Dead Center for No. 1 (L.H.>andNo.4(R.H.) cylinders

... Top Dead Center for No. 1 (L.H.>andNo.4(R.H.) cylinders

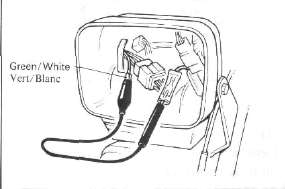

2. Connect the timing light to No. 1 (L.H.) spark plug lead wire.

3. Start the engine and keep the engine speed as specified. Use a tachometer to check the engine speed.

Specified engine speed: 1,050 r/min

4. The stationary pointer should be within the limits of " U " on the timing plate. If it exceeds the limits or does not steady, check the timing plate for tightness and/or ignition system for damage. (See "ELECTRICAL")

CAUTION

Never bend the stationary pointer.

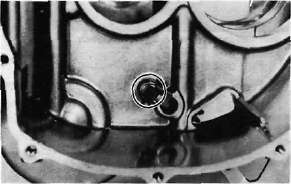

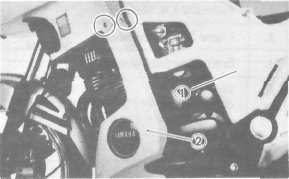

1, Timing plate 2. Stationary pointer

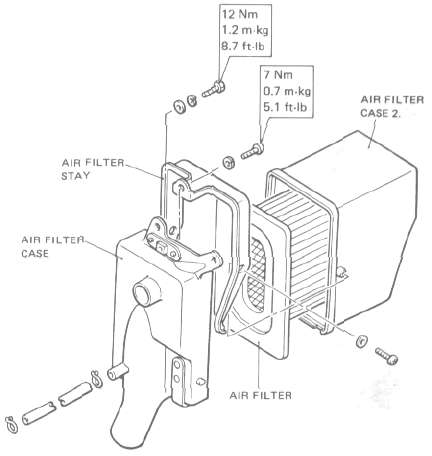

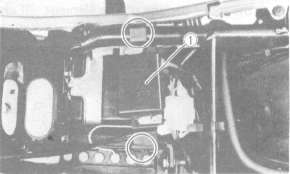

E. Air filter

1. Removal

a. Remove the seat.

b. Remove the fuse box.

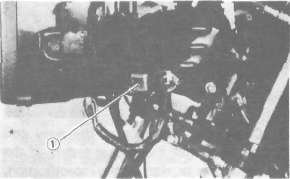

1. Fuse box

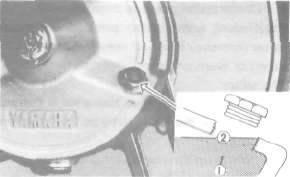

c. Remove the air filter case securing screw. Then, pull the air filter case holding plate backward.

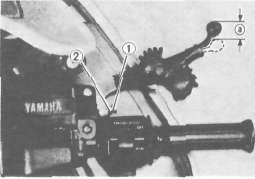

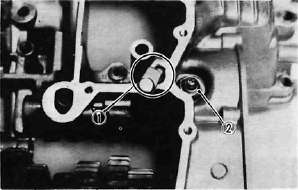

1. Securing screw 2. Holding plate

d. Pull out the air filter case.

e. Pull out the element.

1. Air filter element

2. Cleaning method

Tap the element lightly to remove most of the dust and dirt; then blow out the remaining dirt with compressed air from the inner surface of the element. If element is damaged, replace it.

3. Reassemble by reversing the removal procedure. Check whether the element is seated completely against the case.

4. The air filter element should be cleaned at the specified intervals.

CAUTION:

The engine should never be run without the air cleaner element installed; excessive piston and/or cylinder wear may result.

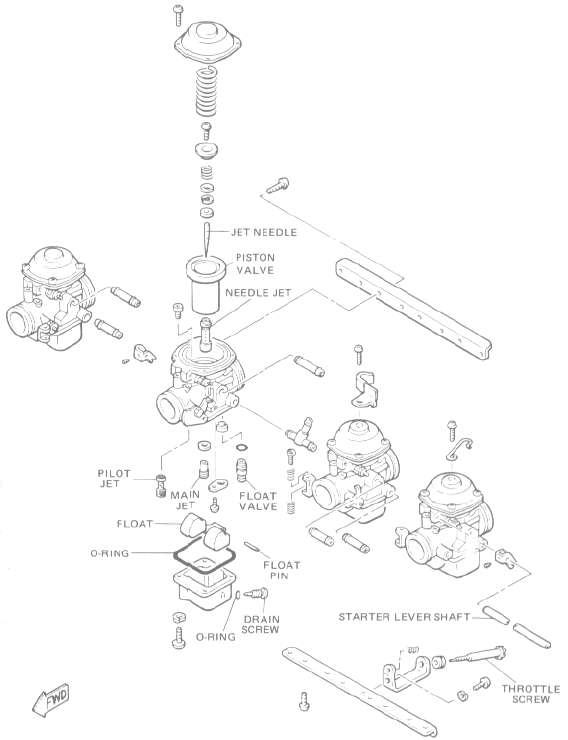

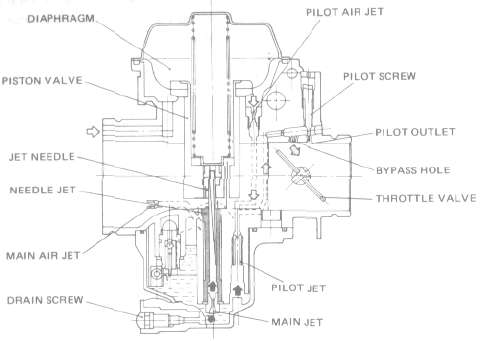

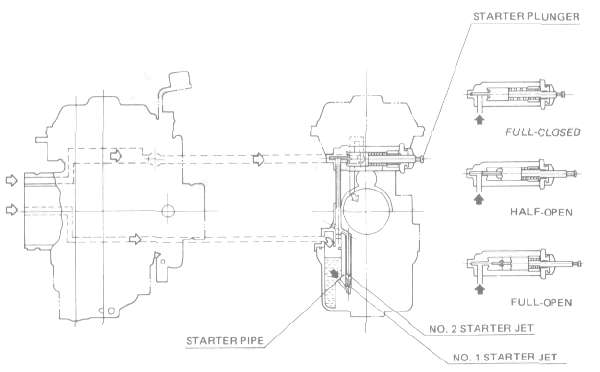

F. Carburetor

Never crank the engine with the fuel lines disconnected from the fuel tank. Fuel will be pumped out, creating a fjre hazard.

Idle mixture

The idle mixture is set at the factory by the use of special equipment. No attempt should be made by the dealer to change this adjustment.

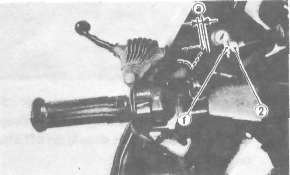

Synchronization

The seat must be removed and the rear of the tank elevated to gain access to the vacuum connections and synchronizing screw.

NOTE:

The valve clearances must be set properly before synchronizing the carburetors.

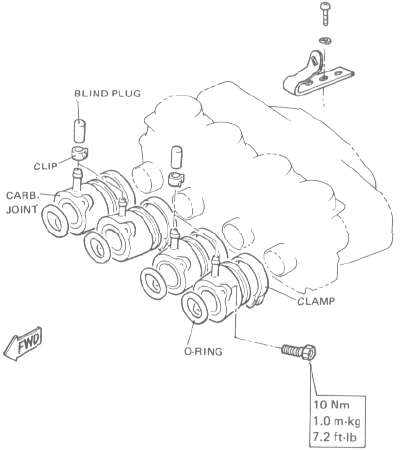

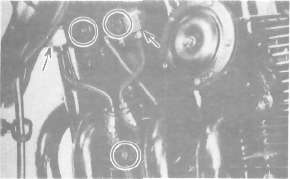

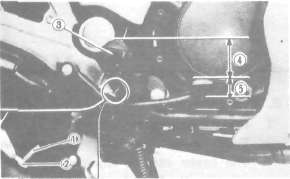

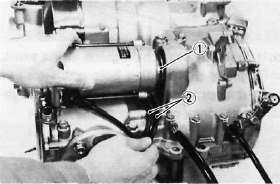

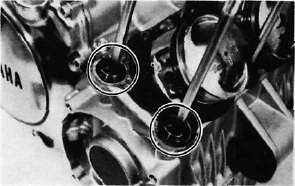

1. Remove the vacuum pipe from the carburetor manifold (No. 3 cylinder) and turn the fuel cock to "PRI."

2. Remove the rubber caps from the No. 1, 2, and 4 carburetor manifolds.

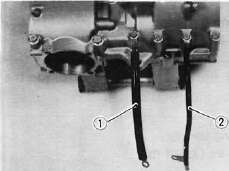

1. Rubber cap

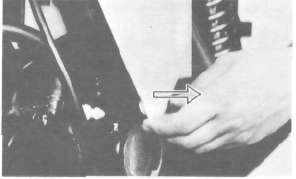

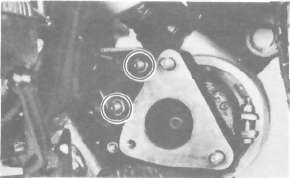

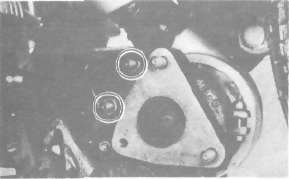

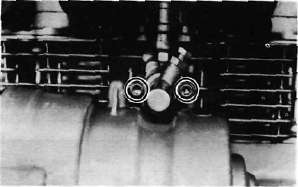

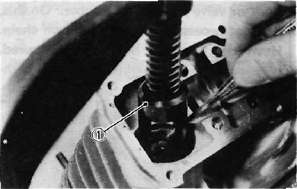

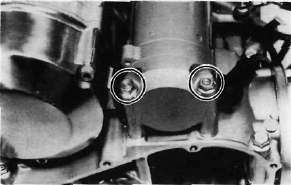

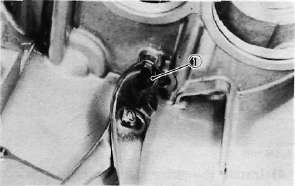

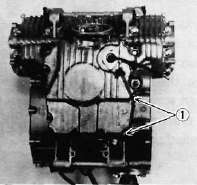

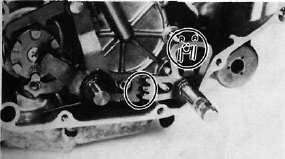

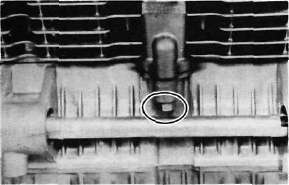

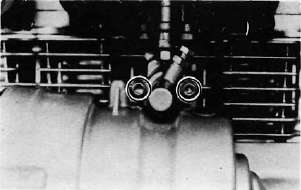

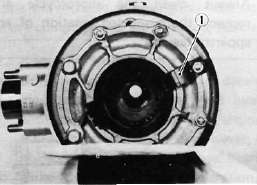

3. Remove either the left or right (but not both) blind plug at the end of the YICS (Yamaha Induction Control System) passage in the cylinder.

1. Blind plug

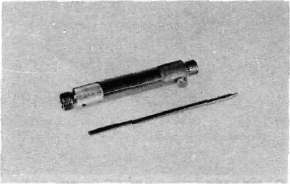

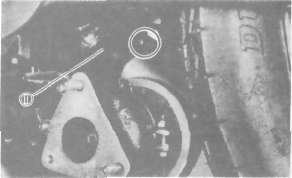

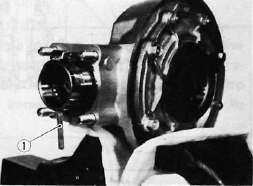

4. Insert the YICS shut-off tool (special tool P/No. 90890-04068) fully and flip the locking lever.

1. Shut-off tool rubber (P/No 90890-04073)

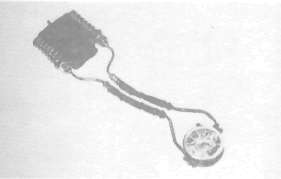

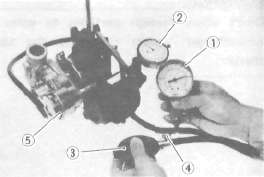

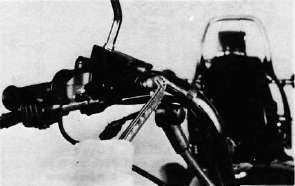

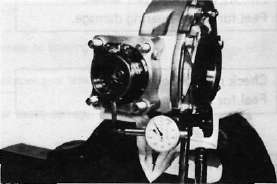

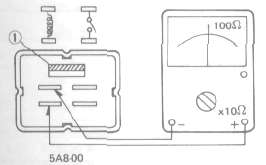

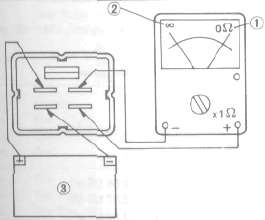

5. Connect each vacuum gauge hose to its proper carburetor.

1. Vacuum gauge

6. Start the engine and allow it to warm up for a few minutes. The warm-up is complete when the engine responds normally to the throttle opening.

7. Make sore the engine idle speed is 950 ~ 1,000 r/min. If it is not, adjust the idle speed with the throttle stop screw.

NOTE:

With the YICS shut off tool fitted, the engine speed generally drops a little. Thus, continue with the following steps at an idle speed of 950-1,000 r/min.

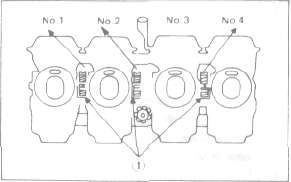

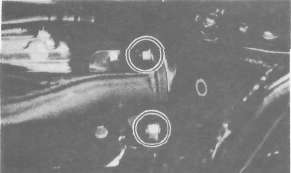

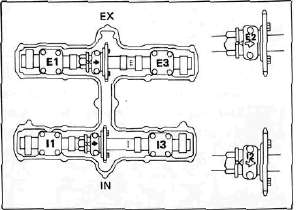

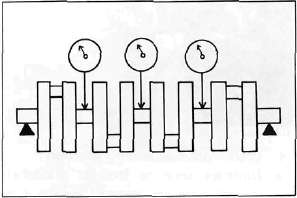

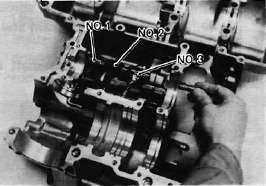

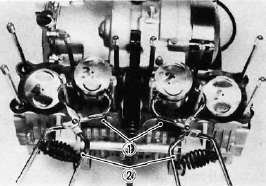

8. Each gauge reading will indicate the same if the carburetors are synchronized. The No. 3 carburetor has no synchronizing screw, and the other carburetors are to be synchronized to it in order, one at a time.

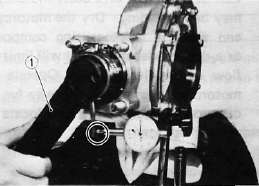

First, synchronize carburetor No. 1 to carburetor No. 2 by turning the No. 1 synchronizing screw until both gauges read the same.

Second, in the same way synchronize carburetor No. 4 to carburetor No. 3. Third, by adjusting No. 2 screw, watch No. 3 carburetor reading. No. 1 and No. 2 carburetors will both change to match No. 3 carburetor.

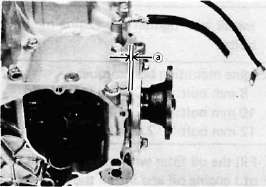

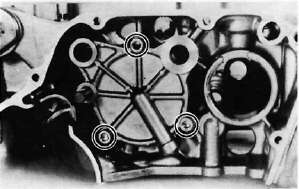

1. Synchronizing screws

9. Remove the YICS shut off tool and reinstall the blind plug.

Tightening torque:

22 Nm (2.2 m-kg, 16 ft-lb)

10. Check the idle speed. Adjust if necessary.

Idle speed adjustment

NOTE

Carburetors must be synchronized before setting the final idle speed. The idle speed adjustment is made by turning only one throttle stop screw.

1. The engine must be warmed up before setting the idle speed.

2. Set the engine idle speed by turning the throttle stop screw in (to increase engine speed) or out (to decrease engine speed).

Standard idle speed: 1,050 ± 50 rpm

1. Throttle stop screw

G. Engine oil

1. Oil level measurement

a. Place the motorcycle on its centerstand. Warm up the engine for several minutes.

NOTE:

Be sure the motorcycle is positioned straight up when checking the oil level; a slight tilt toward the side can produce false readings.

b. With the engine stopped, check the oil level through the level window located at the lower part of the light side crank case cover.

NOTE:

Wait a few minutes until the oil level settle before checking.

d. Remove the drain plug and drain the oil.

1. Maximum mark 2. Minimum mark 3. Level window

c. The oil level should be at the maximum level. If the level is lower, add sufficient oil to raise it to the maximum level.

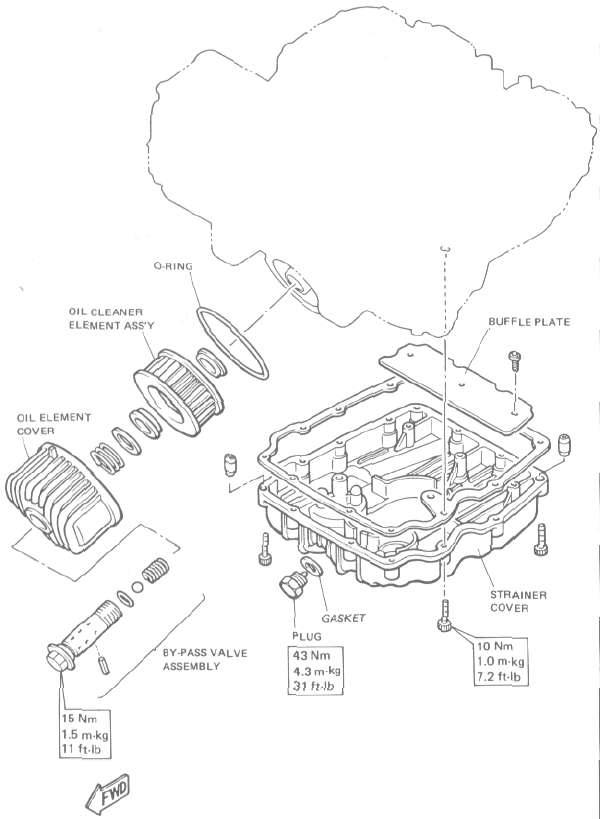

2. Engine oil and oil filter replacement

a. Start the engine and run it a few minutes to warm it up.

b. Place an oil pan under the engine and remove the oil filler cap.

c. Remove the lower panel.

1 Lower panel

1. Drain plug

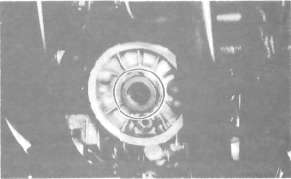

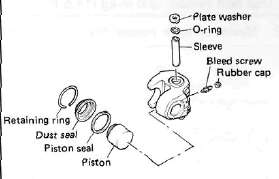

e. Remove the oil filter bolt and filter element.

1. Oil filter cover

f. Reinstall the drain plug (make sure it is tight).

Drain plug torque: 43 Nm (4.2 m-kg, 31.0 ft-lb)

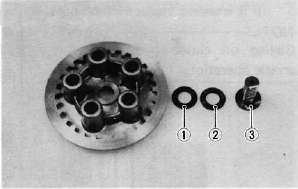

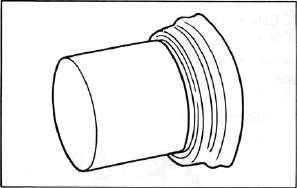

g. Install the new oil filter element, new O-ring and filter cover; tighten the oil filter bolt.

Oil filter bolt torque:

15 Nm (1.5 m-kg, 11.0 ft-lb)

NOTE:

Make sure the O-ring is positioned properly.

1 - Proper O-ring position

h. Add oil through the oil filler hole.

Periodic oil change:

2.5 L (2.2 Imp. qt. , 2.6US qt.) With oil filter replacement:

2.9 L (2.6 Imp qt, 3.1 US qt.) Recommended oil:

YAMALUBE 4-cycle oil or SAE

20W40 type SE motor oil

CAUTION:

Take care not to allow foreign material to enter the crankcase.

i. After replacing engine oil, and/or the oil filter, be sure to check for oil leakage. The oil indicator light should go off after oil is filled.

CAUTION:

If the indicator light flickers or remains on, the oil level switch may be damaged. Refer to ELECTRICAL for corrective action.

j. Reinstall the lower panel.

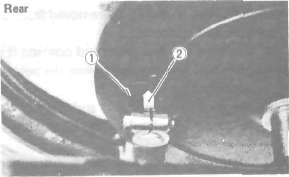

H. Final gear oil

1. Oil level measurement

a. Place the motorcycle on a level place and place it on the centerstand. The engine should be cool (at atmospheric temperature).

b. Remove the oil filler cap and check the oil level whether it is to the hole brim. If it is not up to this level, replenish oil.

CAUTION:

Take care not to allow foreign material to enter the final gear case.

1. Final gear oil 2. Correct oil Level

2. Gear oil replacement

a. Place an oil pan under the final gear case.

b. Remove the final gear oil filler cap and the drain plug, and drain the oil.

1. Final gear drain plug

WARNING:

When draining or filling, take care not to allow foreign material to enter the final gear case. Do not allow the gear oil to contact the tire and wheel.

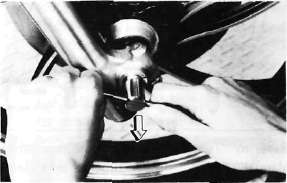

c. Reinstall and tighten the final drain plug.

Tightening torque: 23 Nm (2.3 m-kg, 17ft-lb)

d. Fill the gear case to the specified level.

Oil capacity: Final gear case: 0.2 L (0.18 Imp. qt. , 0.21 US qt.)

Recommended oil: SAE 80 API "GL-4" Hypoid gear oil. If desired, an SAE 80W90 hypoid gear oil may be used for all conditions.

e. Reinstall the filler cap securely.

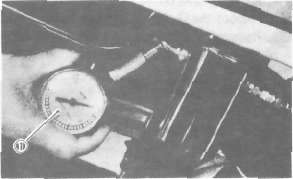

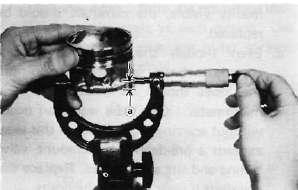

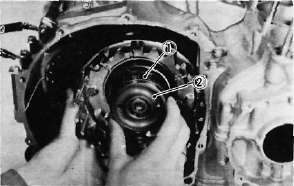

I. Compression pressure measurement

Insufficient compression pressure will result in performance loss and may indicate leaking valves or worn or damaged piston rings.

Procedure:

1. Make sure the valve clearance is correct.

2. Remove the headlight fuse from the fuse box.

3. Warm up the engine 2 ~ 3 minutes. Stop the engine.

4. Remove the all spark plugs.

5. Install a compression-check gauge.

6. Turn over the engine with the electric starter (make sure the battery is fully charged) with the battery is fully charged) with the throttle wide open until the pressure indicated on the gauge does not increase further.

Compression pressure (at sea level):

Standard 834 kPa (8.5 kg/cm2, 121 psi)

Minimum 686 kPa (7 kg/cm2, 100 psi)

Maximum 981 kPa (10 kg/cm2, 142 psi)

When cranking the engine, ground the removal spark plug wires to prevent sparking.

1. Compression gauge

7. If the pressure is too low, squirt a few drops of oil into the cylinder being measured. Measure compression again. If there is a higher reading than before (without oil), the piston rings may be worn or damaged. If the pressure remains the same after measuring with the oil, either or both the rings and valves may be the cause.

8. Check each cylinder. Compression pressure should not vary more than the specified value from one cylinder another.

Difference in gauge reading: Less than 98.1 kPa (1.0 kg/cm2, 14 psi)

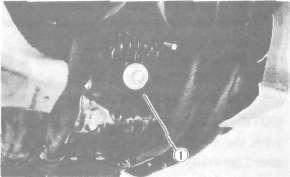

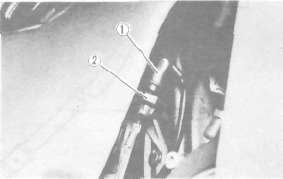

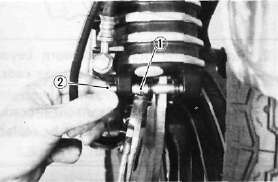

J. Clutch adjustment

Free play adjustment

1. Locknut 2. Adjuster. 2—3 mm (0.08—0.12 in)

a. Loosen either the handle lever adjuster lockout or the cable length-adjuster lock-nut.

1 Locknut 2. Adjuster

b. Turn the cable length-adjuster either in or out until the proper lever free play is achieved.

Chassis Maintenance

Chassis MaintenanceCHASSIS

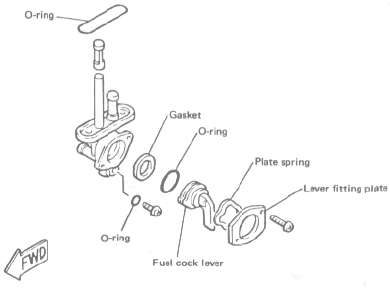

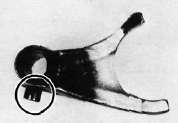

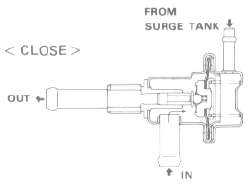

A. Fuel petcock

If the fuel petcock is leaking or excessively contaminated, it should be removed from the fuel tank and inspected.

1. Remove the fuel tank, and position it so that fuel wilt not spill when the petcock is removed.

2. Remove the petcock and inspect the filter screen. Replace the filter if srious-ly contaminated.

3. Remove the screws on the front and rear of the petcock and remove the plate, gaskets, lever, and diaphragm.

4. Inspect all components and replace any that are damaged. If the diaphragm is in any way damaged, or the petcock body gasket surfaces scratched or corroded, the petcock assembly must be replaced. If there is abrasive damage to any component, the fuel tank must be drained and flushed.

5. Reassemble the petcock and install it on the fuel tank.

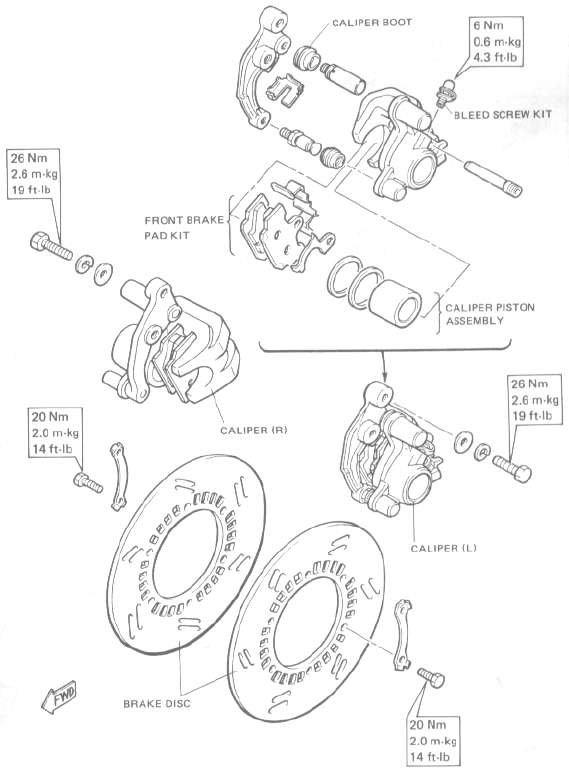

B. Front and rear brake

1. Brake adjustment

a. Front brake lever free play adjustment. The brake can be adjusted by simply adjusting the free play of the brake lever. The piston in the caliper moves forward as the brake pad wears out, automatically adjusting the clearance between the brake pads and brake disc.

CAUTION:

Proper lever free play is essential to avoid excessive brake drag.

1. Adjuster 2. Lock nut a. 5 - 8 mm (0.2 - 0.3 in)

1) Loosen the adjuster locknut on the brake lever.

2) Turn the adjuster so that the brake lever movement at the lever end is 5- 8 mm (0.2-0.3 in) before the adjuster contacts the master cylinder piston.

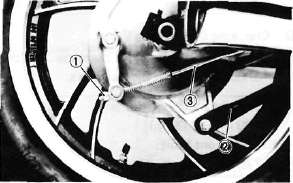

3) After adjusting, tighten the locknut. b. Rear brake pedal height adjustment

1) Loosen the adjuster locknut {for pedal height).

2) By turning the adjuster bolt clockwise or counterclockwise, adjust the brake pedal position so that its top end is approximately 20 mm {0.78 in) below the footrest top end.

3) Secure the adjuster locknut.

WARNING:

After adjusting the pedal height, the brake pedal free play should be adjusted.

1. Adjuster bolt (for pedal height) 2. Locknut 3. Footrest

4. Pedal height 40 mm (1.6 In) 5. Free play 20 30 mm (0.8 - 1.2 in)

c. Rear brake pedal free play adjustment Turn the adjuster on the brake rod clockwise or counterclockwise to provide the brake pedal with a free play of 20~30 mm {0.8-1.2 in).

1. Adjuster

WARNING:

Check the operation of the brake light after adjusting the rear brake.

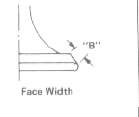

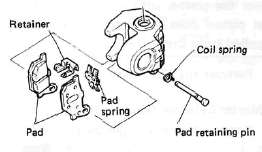

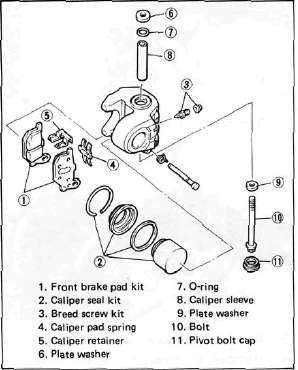

2. Front brake pad and rear brake shoe check

a. Front brake pad

To check, look at the pad in front. If any pad is worn to the wear limit, replace both pads in the caliper.

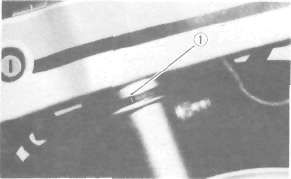

1. Wear indicator

b. Rear brake shoe

To check, see the wear indicator position while depressing the brake pedal. If the indicator reaches to the wear limit line, replace the shoes.

1. Wear limit 2. Wear indicator

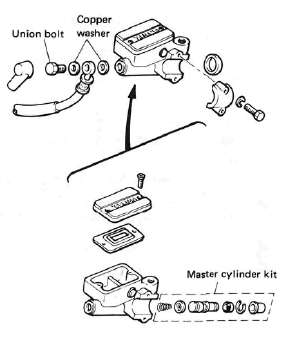

3. Brake fluid

Insufficient brake fluid may allow air to enter the brake system, possibly causing the brake to become ineffective. Check the brake fluid level and replenish when necessary, observing these precautions:

1. Lower level

a. Use only the designated quality brake fluid; otherwise, the rubber seals may deteriorate, causing leakage and poor brake performance.

Recommended brake fluid: DOT# 3

b. Refill with the same type and brand of brake fluid; mixing fluids may result in a harmful chemical reaction and lead to poor performance.

c. Be careful that water or other contamination does not enter the master cylinder when refilling. Water will significantly lower the boiling point and may result in vapor lock.

d. Brake fluid may erode painted surfaces or plastic parts. Always clean up spilled fluid immediately.

e. Check the cause if the brake fluid level goes down.

Brake fluid replacement

1. Complete fluid replacement should be done only by trained Yamaha service personnel or other qualified mechanic.

2. Complete fluid replacement should be done whenever the caliper cylinder or master cylinder is disassembled, or the fluid becomes seriously contaminated.

3. Replace the following components whenever damaged or leaking, also:

a. Replace all brake seals every two years.

b. Replace all brake hoses every four years.

Brake light switch adjustment

The brake light switch is operated by the movement of the brake pedal. To adjust, hold the switch body with the hand so it does not rotate and turn the adjusting nut. Proper adjustment is achieved when the brake light comes on slightly before the brake begins to take effect.

1. Switch body 2. Adjusting nut

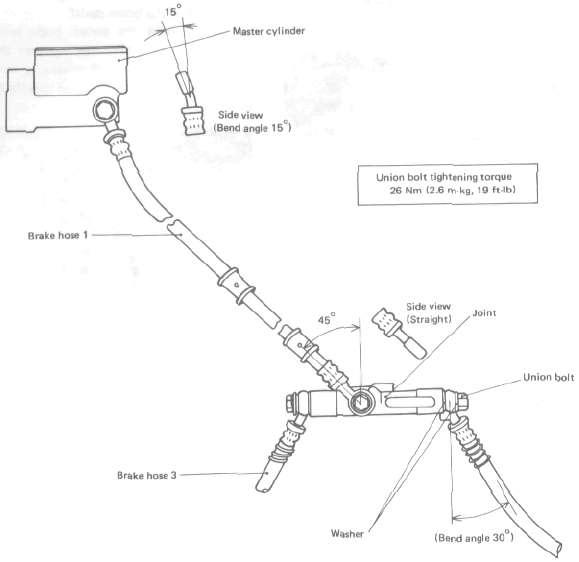

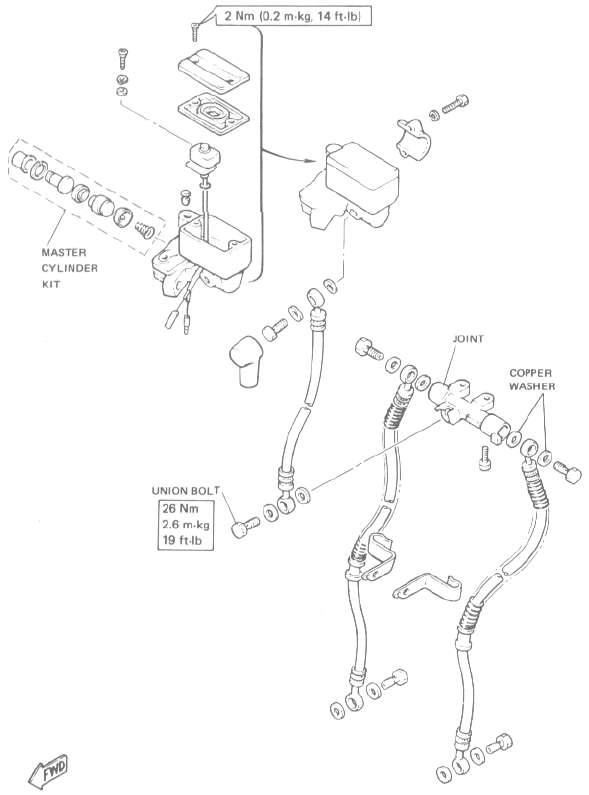

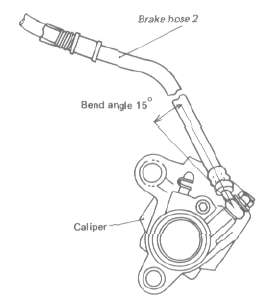

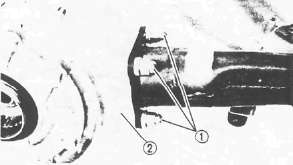

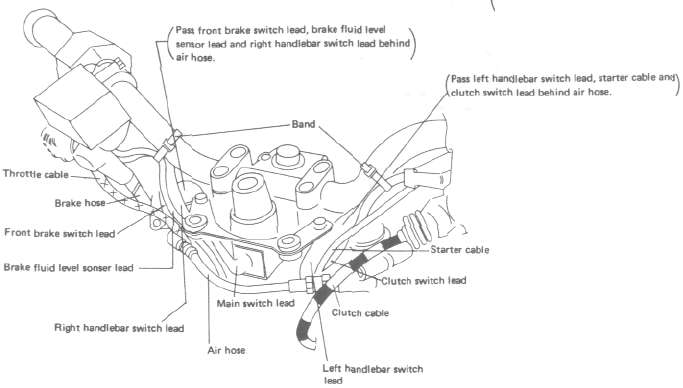

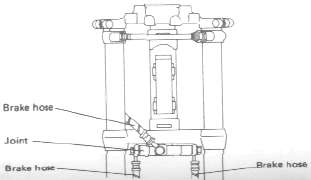

Front brake hose installation

The front brake hoses should be installed as shown in the illustration.

NOTE:

1. When installing the brake hose to the master cylinder, the joint, or the caliper, pay attention to the banjo fitting angle; see the illustration.

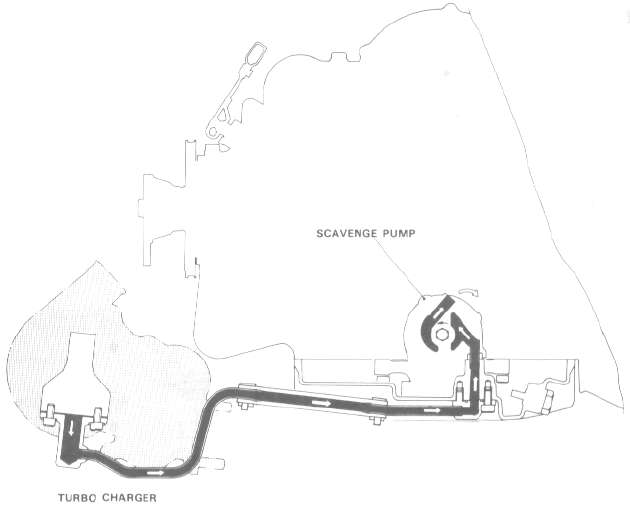

2. When installing the banjo fitting to the caliper or the joint, use the stopper.

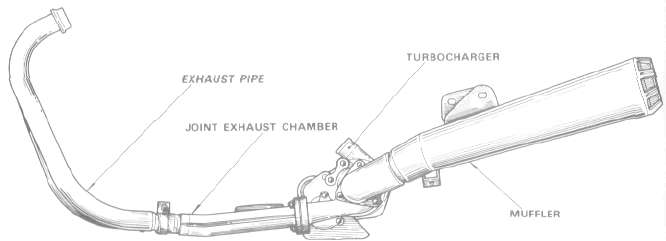

3. When installing the banjo fitting to the master cylinder, brake hose 1 should not have any excessive twists or bends in it, nor should it be tightly stretched.

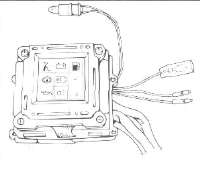

FRONT BRAKE HOSE INSTALLATION

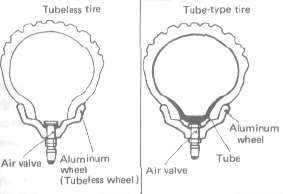

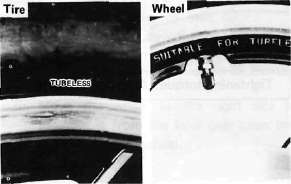

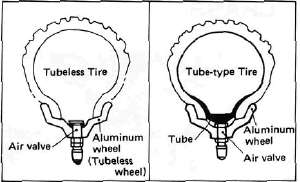

C. TubeIess tires and aluminum wheels

This motorcycle is equipped with aluminum wheels designed to be compatible with either tube or tubeless tires. Tubeless tires are installed as standard equipment.

WARNING:

Do not attempt to use tubeless tires on a wheel designed for use only with tube-type tires. Tire failure and personal injury may result from sudden deflation.

Tube-type Wheel -> Tube-type tires only

Tubeless type Wheel -> Tube-type or Tubeless tires

When using tube-type tires, be sure to install the proper tube also.

To insure maximum performance, long service, and safe operation, note the following precautions.

1. Check tire pressure before riding; adjust as necessary.

2. Before operation, always check the tire surfaces for wear and/or damage; look for cracks, glass, nails, metal fragments, stones, etc. Correct any such hazard before riding.

3. Always inspect the aluminum wheels before a ride. Place the motorcycle on its centerstand and check for cracks, bends, or warpage of the wheels. Do not attempt even small repairs to the wheel. If a wheel is deformed or cracked, it must be replaced.

4. Tires and wheels should be balanced whenever either one is changed or replaced. Failure to have a wheel assembly balanced can result in poor performance, adverse handling characteristics, and shortened tire life.

5. After installing a tire, ride conservatively to allow the tire to seat itself on the rim properly. Failure to allow proper seating may cause tire failure, resulting in damage to the motorcycle and injury to the rider.

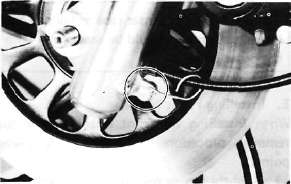

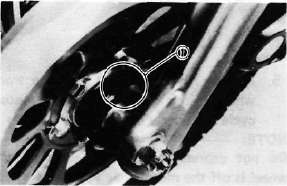

6. After repairing or replacing a tire, check to be sure the valve stem locknut is securely fastened. If not, torque it as specified.

Tightening torque: 0.15 m-kg (1.1 ft-lb)

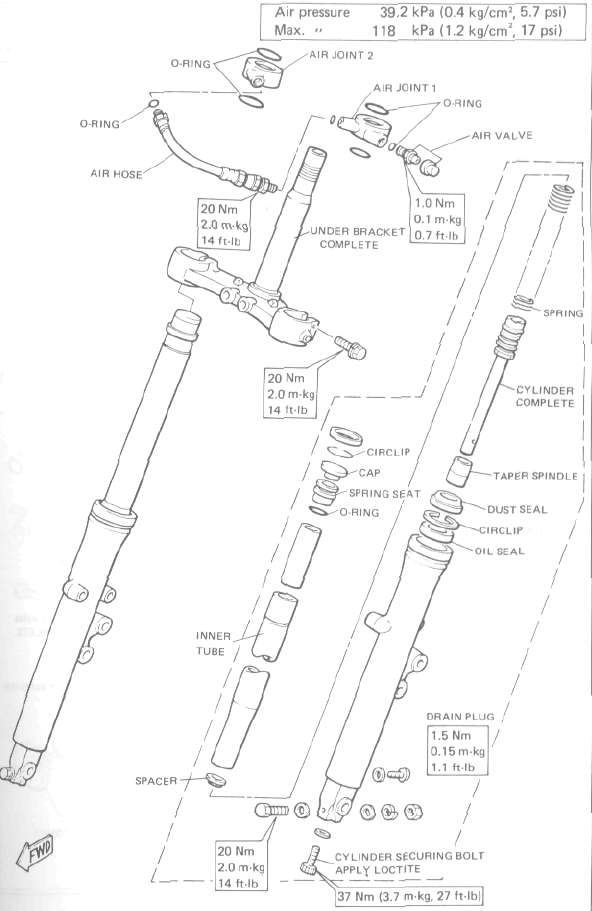

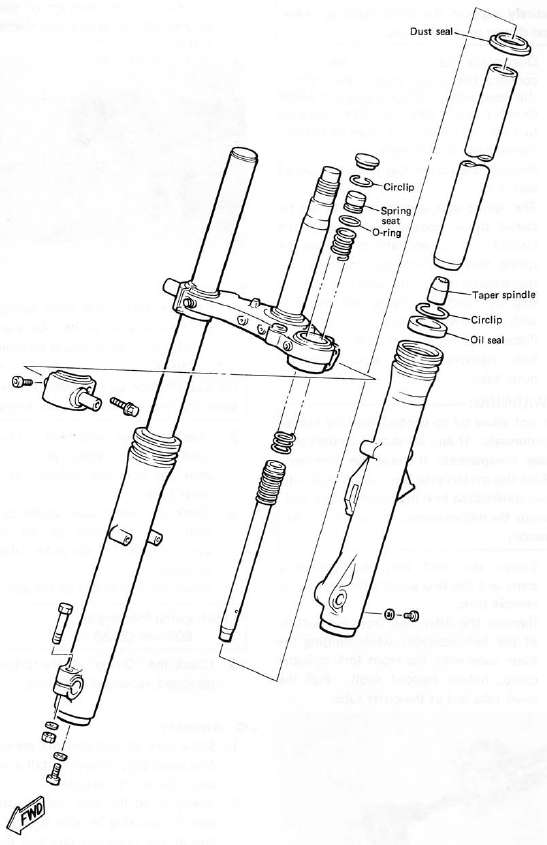

D. Front fork oil change

NOTE:

It is recommended that you proceed to the front fork oil change after clearing the front fork area of the fairing. This makes the work easier without the fairing being damaged.

WARNING:

1. Fork oil leakage cause loss of stability and safe handling. Oil can contaminate front brakes causing loss of braking power. Have any problem corrected before operating the motorcycle.

2. Securely support the motorcycle so there is no danger of it falling over.

1, Raise the motorcycle or remove the front wheel so that there is no weight on the front end of the motorcycle.

2. Remove the handlebar cover and handlebars.

3. Remove the air valve cap from the left fork.

1, Air valve cap

4. Keep the valve open while pressing it for several seconds so that the air can be let out of the inner tube.

l.Push

5. Remove the rubber cap from the top of each fork.

6. Loosen the pinch bolts and remove the cap bolt from each inner tube.

1. Cap bolt 2 Pinch bolt

7. Place an open container under each drain hole. Remove the drain screw from each outer tube.

WARNING:

Do not allow oil to contact the disc brake components. If any oil should contact the brake components, it must be removed before the motorcycle is operated. Oil will cause diminished braking capacity and will damage the rubber components of the brake assembly.

1. Drain screw

8. When most of the oil has drained, slowly raise and lower the outer tubes to pump out the remaining oil.

9. Inspect the drain screw gasket. Replace if damaged. Reinstall the drain screw.

10. Pour the specified amount of oil into the fork inner tube.

Front fork oil (each fork): 238 cm3 (8.4 Imp oz, 8.0 US oz) Yamaha Fork Oil 10wt or equivalent

11. After filling, slowly pump the outer tubes up and down to distribute the oil.

12. Inspect the 0-ring on the cap bolt.

13. Reinstall the cap bolt and the rubber cap. Then, tighten the pinch bolts.

Tightening torque:

Cap bolt: 20 Nm (2.0 m-kg, 14.0 ft-lb)

Pinch bolt: 17 Nm (1.7 m-kg, 12.0 ft-lb)

14. Fill the fork with air using a manual air pump or other pressurized air supply. Refer to "Front fork and rear shock absorber adjustment" for proper air pressure adjusting.

Maximum air pressure: 118 kPa (1.2 kg/cm2, 17 psi)

Do not exceed this amount.

15. Reinstall the air valve cap to the left fork.

16. Reinstall the handlebars and handlebar cover.

NOTE:

First tighten the bolts on the front side of the handlebar holder, and then tighten the bolts on the rear side.

Handlebar upper holder tightening torque: 19 Nm (1.9 m-kg, 13.0 ft-lb)

1.1st 2. 2nd 3. Gap 4. Punch mark

Front fork and rear shock adjustment

CAUTION:

Don't dent the air chamber nor damage the air hose. It will result in an air leakage.

Front fork:

NOTE:

Since the right and left front forks are connected by air hose, there is only one valve where the air pressure is measured and adjusted.

1. Air pressure

a. Elevate the front wheel by placing the motorcycle on the centerstand.

NOTE:

When checking and adjusting the air pressure, there should be no weight on the front end of the motorcycle.

b. Remove the air valve cap.

c. Using the air check gauge, check and adjusted the air pressure. If the air pressure is increased, the suspension becomes stiffer and if decreased, it becomes softer.

To increase: Use a manual air pump or other pressurized air supply.

To decrease: Release the air by pushing the valve pin.

1. Air check gauge

NOTE:

An optional air check gauge is available. P/No. 2X4-2811A-00

Standard air pressure: 39.2 kPa (0.4 kg/cm3, 5.7 psi)

Maximum air pressure: 118 kPa (1.2 kg/cm2, 17 psi)

Minimum air pressure: 39.2 kPa (0.4 kg/cm2, 5.7 psi)

CAUTION:

Never exceed the maximum pressure or oil seal damage may occur.

WARNING:

Never pressurize the front fork above the maximum or below the minimum air pressure. It will cause damage to front fork and/or loss Of motorcycle control.

d. Reinstall the air valve cap.

E. Rear shock absorber

NOTE:

Since the right and left shock absorbers are connected by air hose, there is only one valve where the air pressure is measured and adjusted.

1. Air pressure

a. Elevated the rear wheel by placing the motorcycle on the centerstand.

NOTE:

When checking and adjusting the air pressure, there should be no weight on the rear end of the motorcycle.

b. Remove the air valve cap.

c. Using the air check gauge, check and adjust the air pressure. If the air pressure is increased, the suspension becomes stiffer, and if decreased, it becomes softer,

To increase: Use a manual air pump or other pressurized air supply,

To decrease. Release the air by pushing the valve pin.

1. Air check gauge

NOTE: An optional air check gauge is available. P/No. 2X4-2811A-00

Standard air pressure: 98.1 kPa (1.0 kg/cm2, 14 psi)

Maximum air pressure: 392 kPa (4.0 kg/cm2, 57 psi)

Minimum air pressure: 98.1 kPa (1.0 kg/cm2, 14 psi)

CAUTION:

Never exceed the maximum pressure or oil seal damage may occur.

WARNING:

Never pressurize the shock absorber above the maximum or below the minimum air pressure. It will cause damage to rear shock absorber and/or loss of motorcycle control.

d. Reinstall the air valve cap.

2. Damping

a. Turning the damping adjuster to increase or decrease the damping.

b. If the damping adjuster is turned toward the "4", the damping becomes harder; if the adjuster is turned toward the "1", damping becomes softer.

Standard position - No. 1

No. 1 - Minimum damping

No. 4 — Maximum damping

1. Damping adjuster

Always the shock absorbers on each side to the same position. Uneven adjustment will cause an improper riding position.

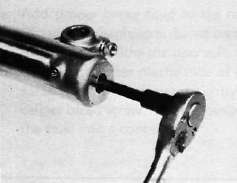

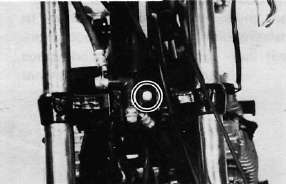

F. Steering head adjustment

The steering assembly should be checked periodically for looseness.

1. Raise the front end of the motorcycle so that there is no weight on the front wheel.

2. Grasp the bottom of the forks and gently rock the fork assembly backward and forward, checking for looseness in the steering assembly bearings.

3. If there is looseness in the steering head, loosen the steering stem and front fork pinch bolts and steering fitting bolt.

4. Use a steering nut wrench to loosen top steering fitting nut. The top nut serves as a locknut.

5. Tighten the lower steering fitting nut until the steering head is tight, but does not bind when forks are turned.

6. Retighten the top steering fitting nut, steering fitting bolt and steering stem and front fork pinch bolts, in that order.

7. Recheck steering adjustment to make sure there is no binding when the forks are moved from lock to lock. If necessary, repeat adjustment procedure.

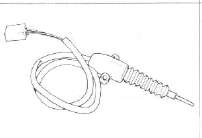

G. Cable inspection and lubrication

Warning:

Damage to the outer housing of the various cables may cause corrosion; free movement could be obstructed. An unsafe condition may result, so replace such cables as soon as possible.

1. If the inner cables do not operate smoothly, lubricate or replace them.

Recommended lubricant:

Yamaha Chain and Cable Lube or SAE 10W30 motor oil

H. Throttle cable and grip lubrication The throttle twist grip assembly should be greased when the cable is lubricated, since the grip must be removed to get at the end of the throttle cable. Two screws clamp the throttle housing to the handlebar. Once these two are removed, the end of the cable can be held high to pour in several drops of lubricant. With the throttle grip disassembled, coat the metal surface of the grip assembly with a suitable all-purpose grease to cut down friction.

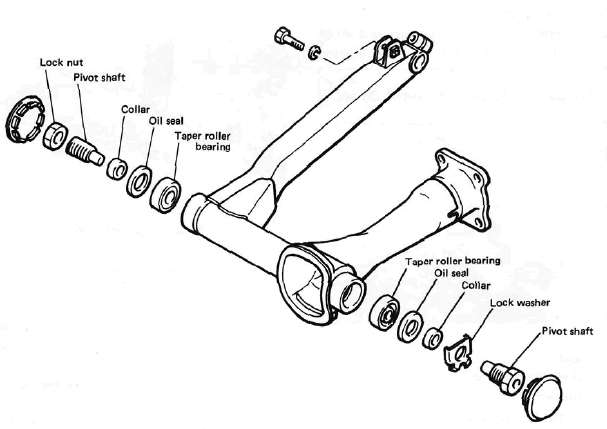

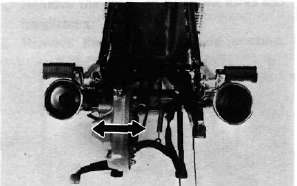

I. Rear arm pivot bearings The swingarm must pivot freely on its bearings but not have any excess play. Check and adjust pivot bearings if necessary.

J. Brake and change pedals/brake and clutch levers Lubricate the pivoting parts of each lever and pedal.

Recommended lubricant:

Yamaha Chain and Cable Lube or SAE 10W30 motor oil

K. Centerstand and sidestand pivots Lubricate the centerstand and sidestand at their pivot points.

Recommended lubricants:

Yamaha Chain and Cable Lube or SAE 10W30 motor oil

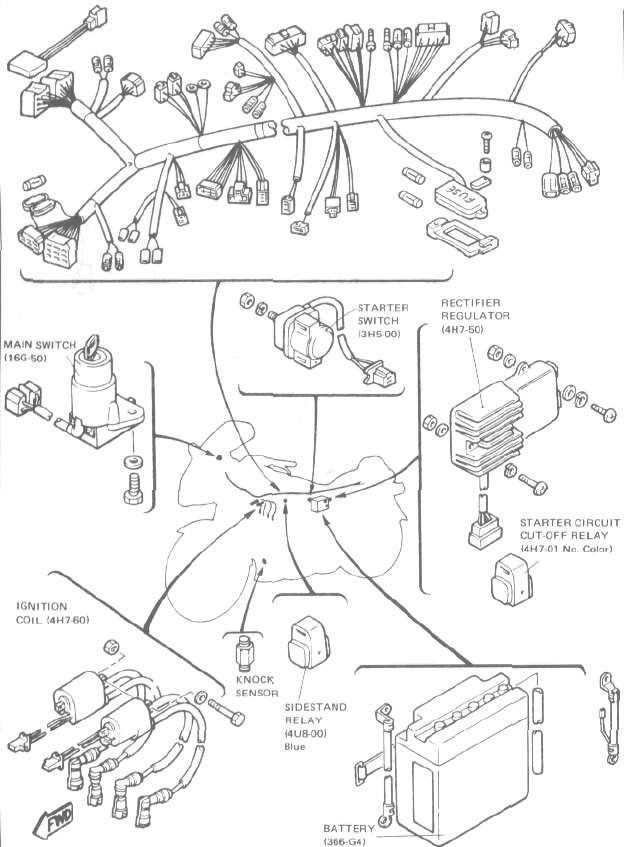

Electrical Maintenance

Electrical MaintenanceELECTRICAL

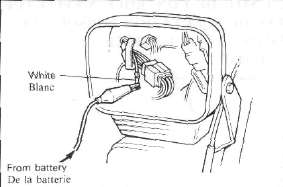

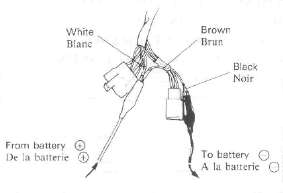

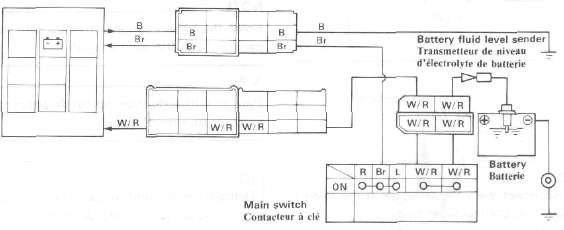

A. Battery

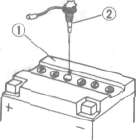

1. The fluid level should be between the upper and lower level marks. Use only distilled water if refilling is necessary.

CAUTION: Normal tap water contains minerals which are harmful to a battery; therefore, refill only with distilled water.

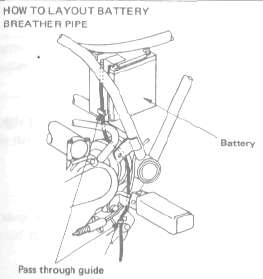

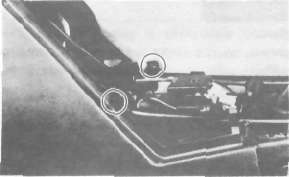

2. Always make sure the connections are correct when installing the battery. Make sure the breather pipe is properly connected, properly routed, and is not damaged or obstructed.

CAUTION: The battery must be charged before using to insure maximum performance. Failure to properly charge the battery before first use or a low electrolyte level will cause premature failure of the battery.

Charging current: 1.2 amps/10 hrs or until the specific gravity reaches 1.280 at 20°C (6°F)

WARNING: Battery electrolyte is poisonous and dangerous, causing severe burns, etc. It contains sulfuric acid. Avoid contact with skin, eyes, or clothing.

Antidote:

EXTERNAL-Flush with water,

INTERNAL -Drink large quantities of water or milk. Follow with milk of magnesia, beaten egg, or vegetable oil. Call physician immediately.

Eyes. Flush with water for 15 minutes and get prompt medical attention.

Batteries produce explosive gases. Keep sparks, flame, cigarettes, etc. away. Ventilate when charging or using in closed space. Always shield eyes when working near batteries. KEEP OUT OF REACH OF CHILDREN.

Replenishing the battery fluid

A poorly maintained battery will deteriorate quickly. The battery fluid should be checked at least once a month.

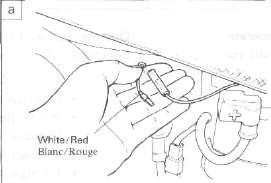

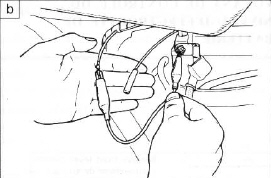

1. Remove the seat.

2. Remove the handlebar cover and side panels (left and right).

3. The level should be between the upper and lower level marks. Use only distilled water if refilling is necessary.

CAUTION: Normal tap water contains minerals which are harmful to a battery; therefore, refill only with distilled water.

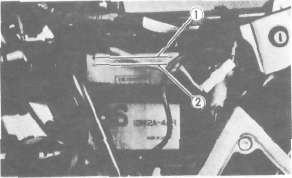

CAUTION: Install the battery sensor into 3RD hole from positive terminal.

1. Upper level 2. Lower level

1. Battery 2. Battery sensor

4. When the motorcycle is not to be used for a month or longer, remove the battery and store it in a cool, dark place. Completely recharge the battery before reusing.

5. If the battery is to be stored for a longer period than the above, check the specific gravity of the fluid at least once a month and recharge the battery when it is too low.

6. Always make sure the connections are correct when putting the battery back in the motorcycle.

Make sure the breather pipe is properly connected and is not damaged or obstructed.

CAUTION: Make sure that the connection to the battery is correct; otherwise, damage to the microcomputer may occur.

7. Reinstall the side panels (left and right) and handlebar cover. Then, reinstall the seat.

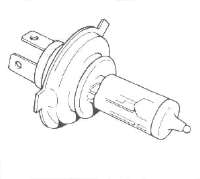

B. Headlight

This motorcycle is equipped with a quartz bulb headlight. If the headlight bulb burns out, replace the bulb as follows:

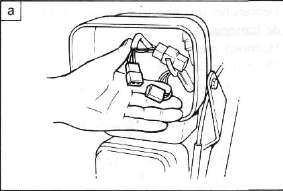

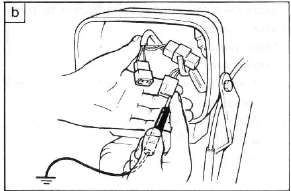

1. Headlight bulb replacement

a. Remove the headlight nacelle.

1. Nacelle holding screw

b. Remove the two blind plugs from the upper panels (left and right).

1. Blind plug

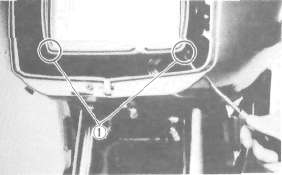

c. Remove the 2 screws holding the light unit assembly to the headlight body.

1. Holding screw

d. Disconnect the leads and remove the light unit assembly.

e. Turn the bulb holder counterclockwise and remove the defective bulb.

1. Bulb holder

f. Slip a new bulb into position and secure it with the bulb holder.

CAUTION: Avoid touching the glass part of the bulb. Also keep it free from oil stains; otherwise, the transparency of the glass, life of the bulb, and luminous flux will be adversely affected. If the glass is oil stained, thoroughly clean it with a cloth moistened with alcohol or lacquer thinner.

WARNING: Keep flammable products or your hands away from the bulb while it is on, because it heats up. Do not touch the bulb until it cools down.

g. For reassembly, follow procedure below with care.

1 ( Install the two blind plugs.

2) Make sure the projecting portions of the headlight nacelle are positioned correctly.

3) Adjust the headlight beam if necessary.

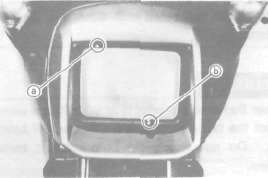

2. Headlight beam adjustment:

a Horizontal adjustment:

To adjust the beam to the left, turn the adjusting screw clockwise.

To adjust the beam to the right, turn the screw counterclockwise.

b. Vertical adjustment:

To adjust the beam to the upper, turn the adjusting screw clockwise.

a. Horizontal adjusting screw b Vertical adjusting screw

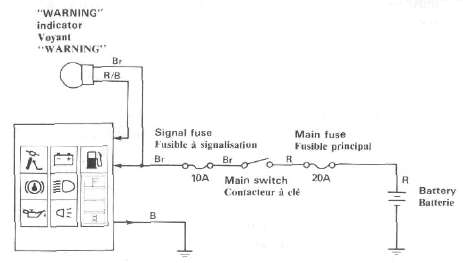

C. Fuse

1. The fuse block is located under the seat.

1. Fuse 2. Spare fuse

2. If any fuse is blown, turn off the ignition switch and the switch in the circuit in question, install a new fuse of proper amperage.

Turn on the switches, and see if the electrical device operates. If the fuse immediately blows again, find the cause in the circuit in question.

WARNING: Do not use fuses of a higher amperage rating than those recommended. Substitution of a fuse of improper rating can cause extensive electrical system damage and possible fire.

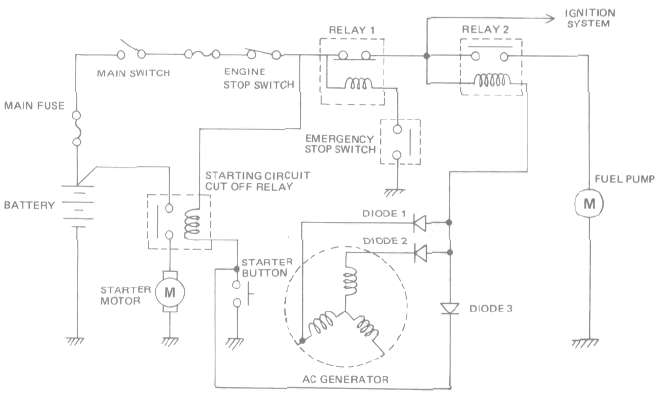

Chapter 3, TURBO SYSTEM

Chapter 3, TURBO SYSTEMSystem Components

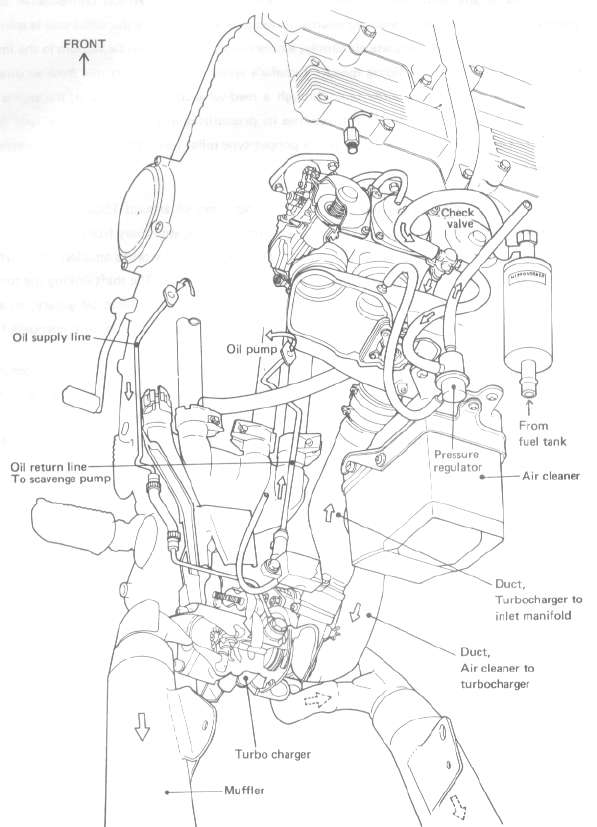

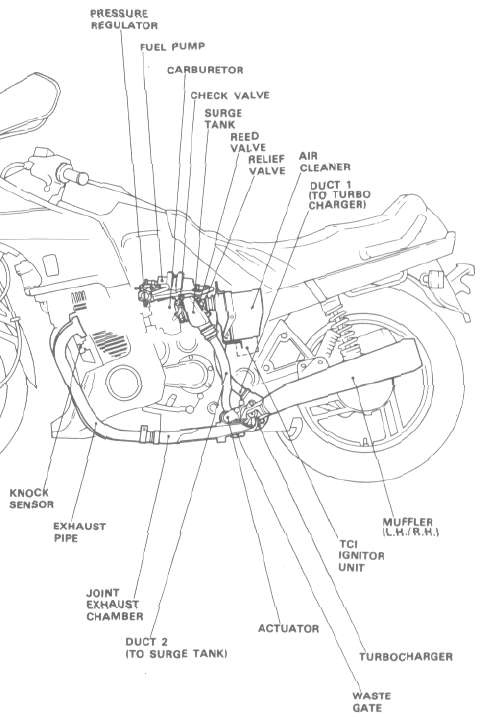

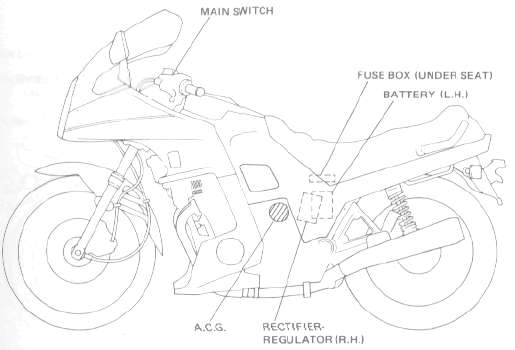

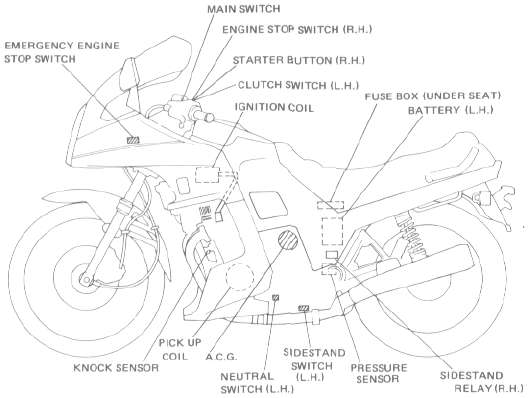

System ComponentsLOCATION AND OUTLINE OF TURBO SYSTEM COMPONENTS

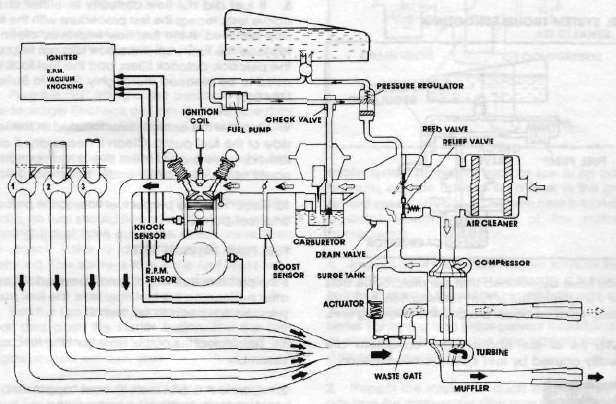

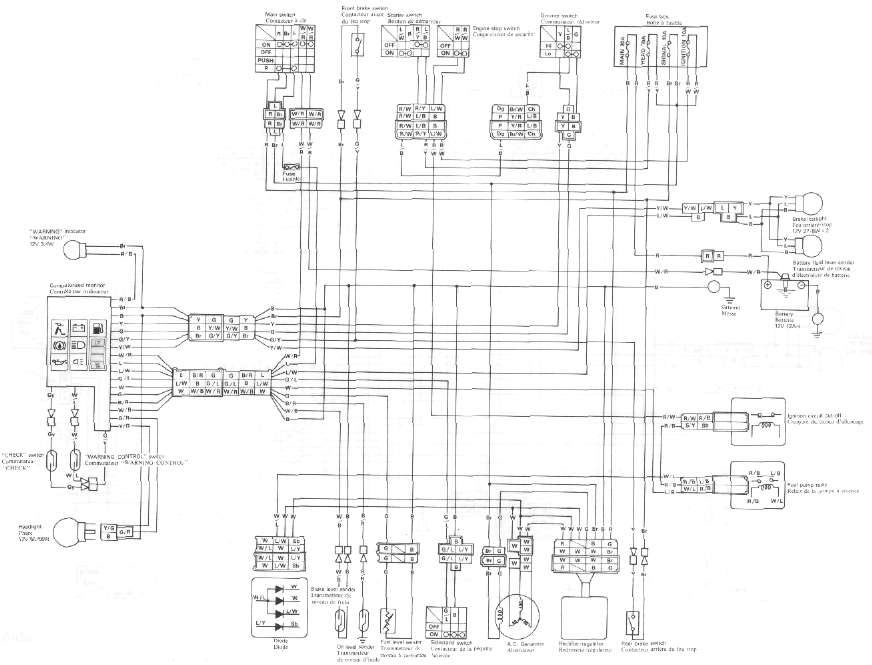

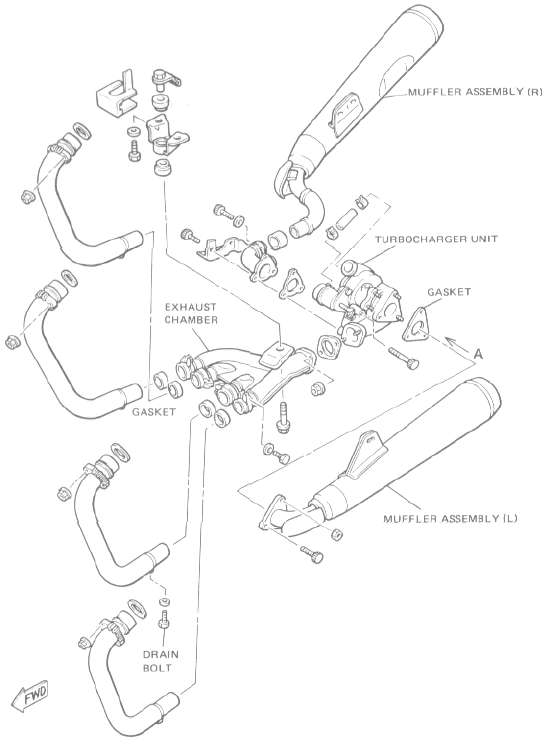

MAJOR COMPONENTS OF THE YAMAHA TURBO SYSTEM

|

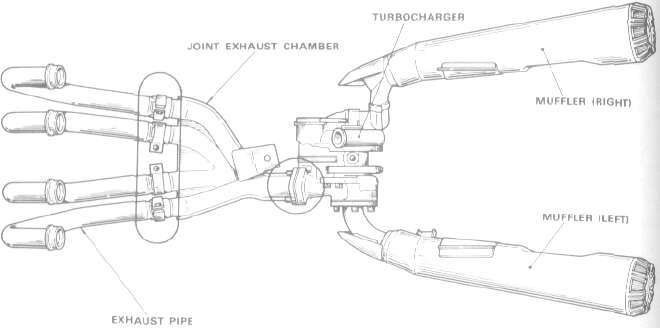

EXHAUST SYSTEM |

(1) Exhaust pipe |

2) Joint exhaust |

(3) Turbocharger |

(4) Actuator |

(5) Wastegate |

(6) Muffler (L.H./R.H ) |

INTAKE SYSTEM |

(1) Air cleaner |

(21 Duct 1 (to turbocharger) |

(3) Duct 2 (to surge tank) |

(4) Surge tank |

(5) Reed valve |

(6) Relief valve |

(7) Drain valve |

FUEL SYSTEM |

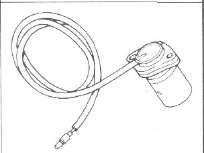

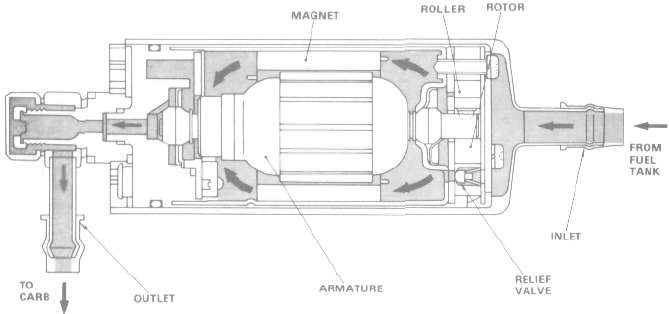

(1) Electric fuel pump |

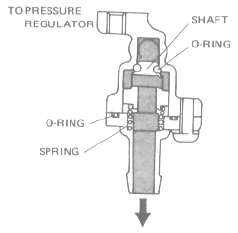

(2) Pressure regulator |

(3) Check valve |

(4) Carburetor |

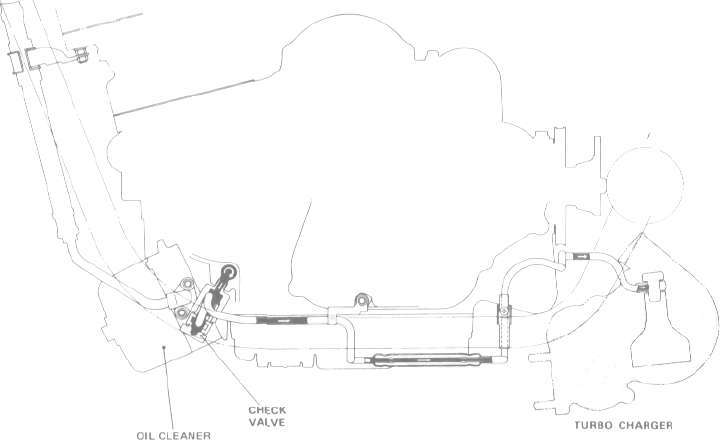

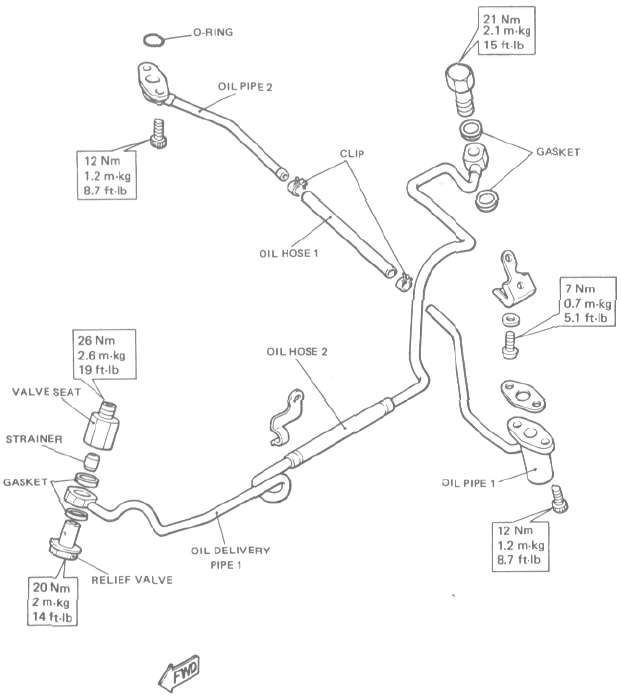

LUBRICATION SYSTEM |

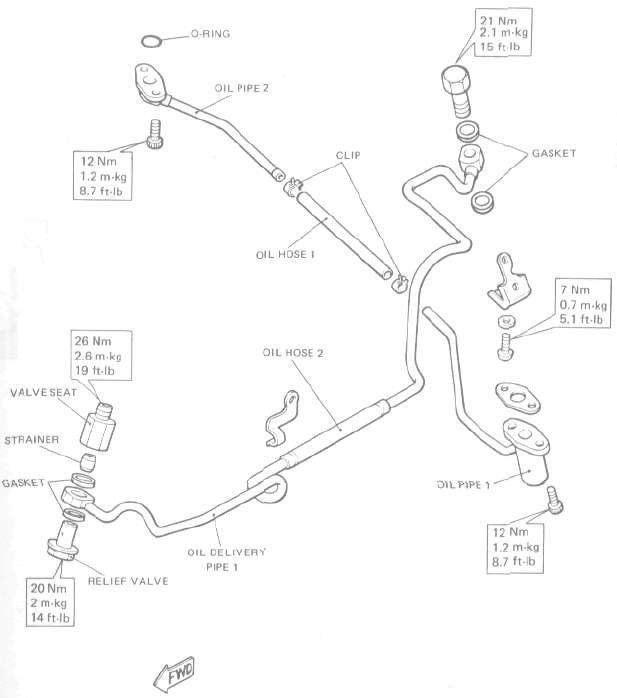

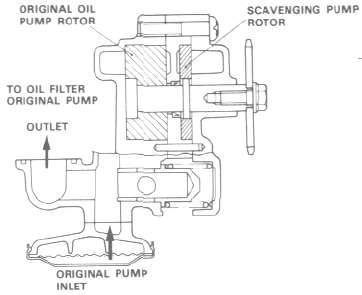

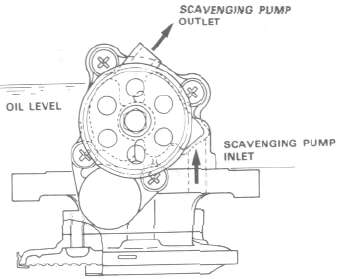

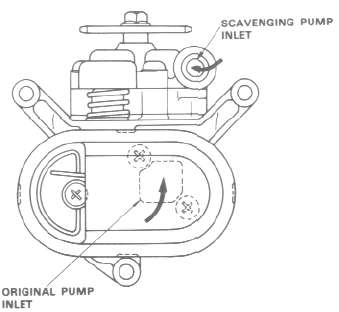

(1) Scavenge pump |

(2) Delivery hose (to turbocharger) |

(3) Scavenge hose (to scavenge pump) |

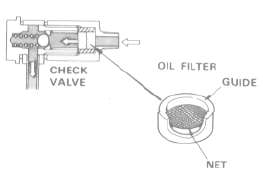

(4) Check valve |

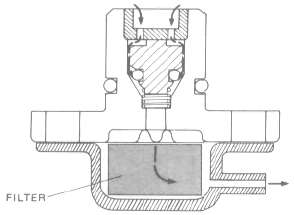

(5) Oil filter |

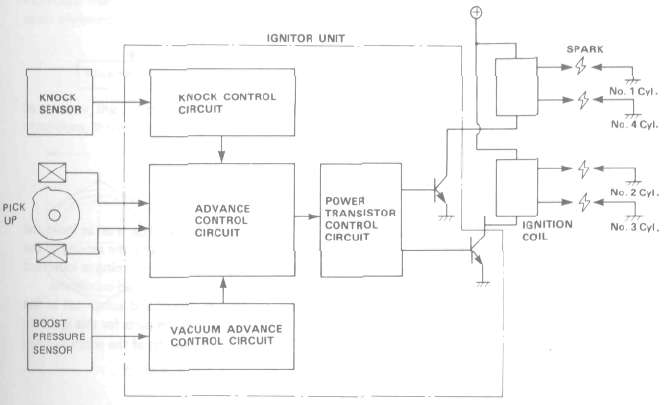

IGNITION SYSTEM |

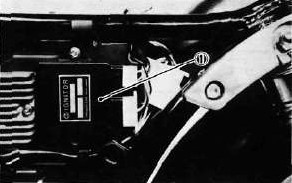

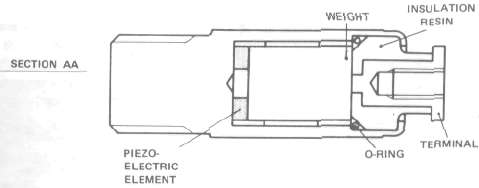

(1) TCI ignitor unit |

(2) Boost sensor |

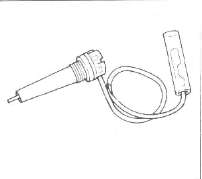

(3) Knock sensor |

CONSTRUCTION OF THE TURBOCHARGER UNIT

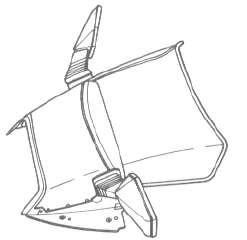

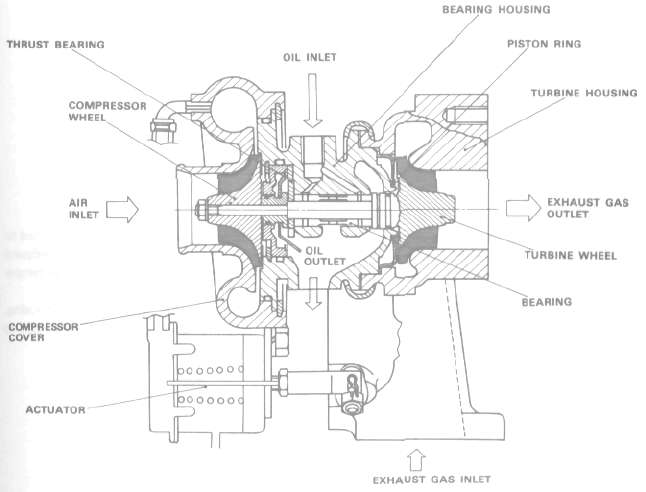

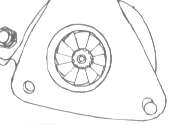

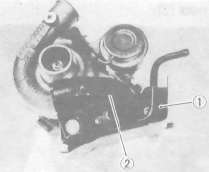

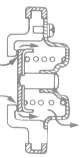

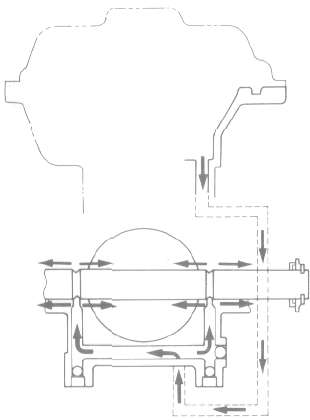

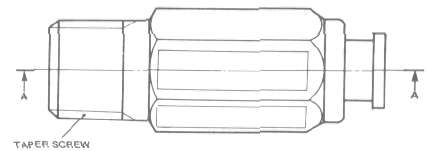

The turbocharger unit is made up of the following components: the compressor, which produces the boost pressure by compressing air; the turbine, which converts the exhaust gas into energy to drive the compressor; the bearings, which support the rotor shaft as it rotates at high speed; and the boost pressure control unit, which is composed of the wastegate and its actuator valve.

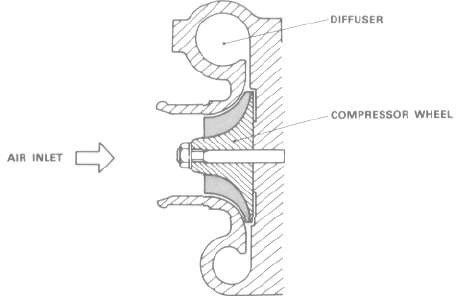

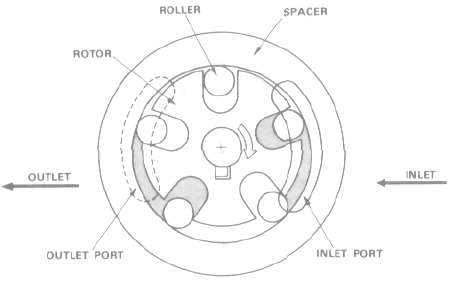

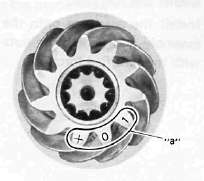

Compressor

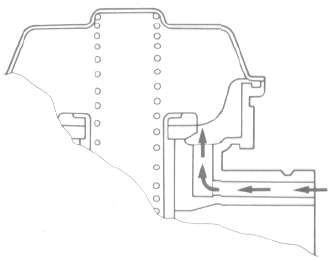

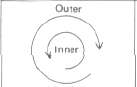

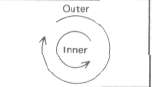

The compressor is a rotor located within a housing of decreasing volume. As the compressor rotor turns, in excess of 100,000 rpm, it moves air by centrifugal force. Because of the design, the air being sent to the carburetors slows from its initial velocity, but because of the decreasing volume of the housing, the air pressure increase.

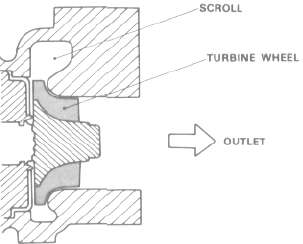

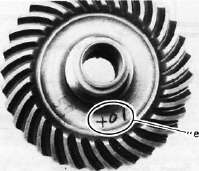

Turbine

The turbine is driven by the engine's exhaust gases. The rotating turbine, which is connected to the compressor, turns the compressor. The turbine rotor is constructed of a ultra heat-resistant alloy, which is a precision casting that can withstand high-speed operation at extreme temperatures. The turbine housing is shaped like a snail and is called a scroll casing. This design directs the exhaust gases into the turbine rotor blades. Because the turbine housing, like the turbine rotor, is subjected to high temperatures, resisting distortion and oxidation due to extremely high temperatures.

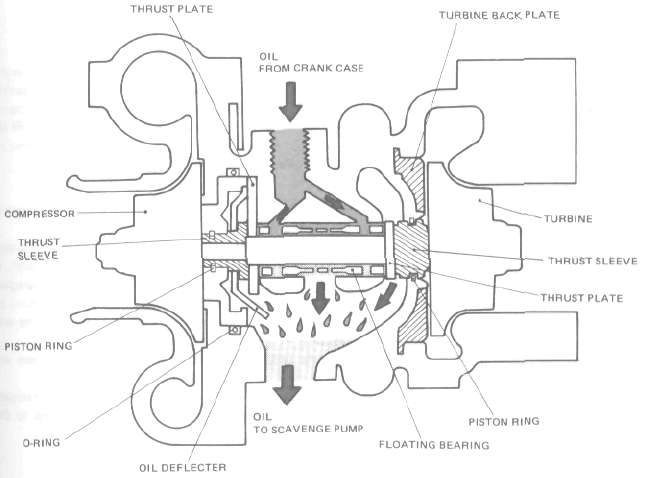

Floating bearing

Floating bearings support the turbine shaft as it turns at speeds of 100,000 to 210,000 rpm. It is the fact that these bearings "float" in a constant flow of lubricating oil that permits the turbine/compressor shaft to spin at such high rpms. These bearings are designed to turn freely between the shaft and the bearing housing. Lubricating oil surrounds the bearings, flowing freely yet absorbing the vibrations created by the turbine/compressor shaft. To ensure that the oil is not stressed any more than necessary, the bearing housing has special seals that separate the exhaust gas driving the turbine from the lubricating oil.

Cooling of the bearing section

During full-throttle, high speed operation the temperature of the inlet at the turbine is more than 850°C. and even the surface temperature of the turbine housing is as high as 550 to 750°C. If such heat is transferred to the center bearing housing, the bearing temperature will rise accordingly. This reduces the oil's viscosity, making it ineffective in absorbing the vibrations from the floating bearing. To guard against these high temperatures, the rear of the turbine is covered with a backing plate so that an air chamber is formed between the backing plate and the housing, thus serving as a heat insulator.

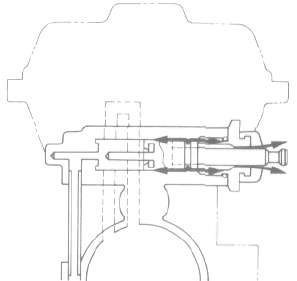

Gas seal on the turbine side

The shaft on the turbine side is provided with a ring groove into which a small-diameter ring is fitted to seal out the exhaust gas from the turbine. The ring is forced against the center bearing housing by its own tension so that it does not turn with the shaft; the shaft rotates while keeping full contact with the ring.

Oil seal on the compressor side

A ring is fitted in the groove around the thrust collar to provide a good seal.

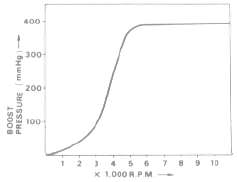

Boost pressure control

When the engine speed is low, that is, when the exhaust gas flow is not much, the boost pressure is also low. But when the engine speed increases, the turbine wheel spins faster, thus increasing the boost pressure. As engine rpms increase, so does boost pressure, further increasing power. If the boost pressure is not controlled, it will increase to the point where the engine will be damaged. To control boost pressure, a valve is used through which exhaust gas is routed to bypass the turbine. Boost pressure is thus controlled.

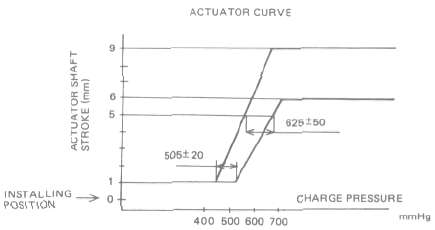

Wastegate valve

The wastegate is opened and closed by the actuator valve which is operated by the boost pressure. The wastegate limits the boost pressure supplied to the engine.

The boost pressure is carried from the compressor, through the rubber hose, to the actuator chamber. When the boost pressure exerted on the chamber goes beyond the preset level, it overcomes the spring force and pushes the diaphragm and linkage. This opens the wastegate valve to permit the exhaust gas to flow to the right-hand muffler. As a result, the amount of exhaust gas exerted on the turbine wheel is reduced, and thus the speed of both turbine and compressor wheels is slowed down. The result is a decrease in the boost. When the boost pressure is below 53.2 kPa (400mmHg, 15.7 inHg), all exhaust gases are channeled through the turbine vanes.

When the boost reaches 53.2 kPa (400 mmHg, 15.7 inHg), the diaphragm of the wastegate actuator causes the gate to open, and the excess exhaust gas flows through the bypass to the exhaust pipe.

Wastegate valve:

Stroke: 5 mm

Pressure: 83.4 ± 6.9 kPa (0.85 ± 0.07 kg/cm2) (12.1 ± 1.0 psi.)

Turbo Troubleshooting

Turbo TroubleshootingINTRODUCTION

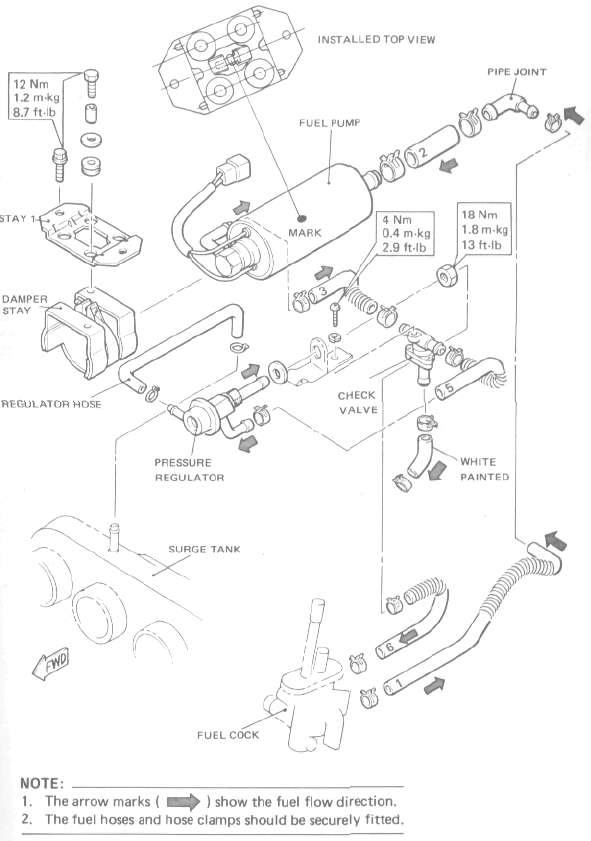

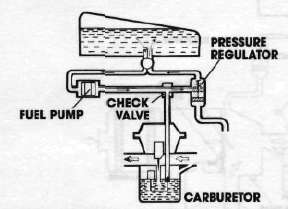

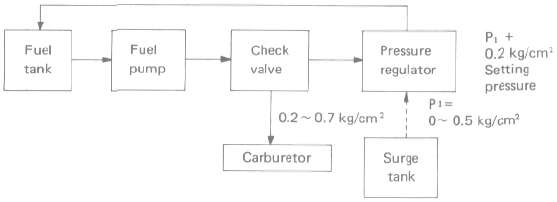

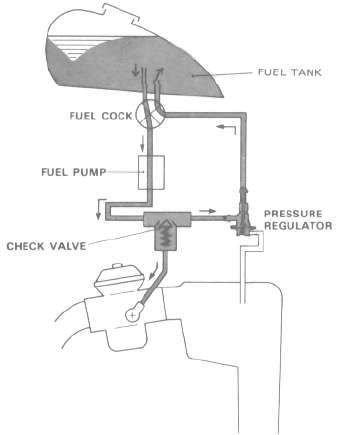

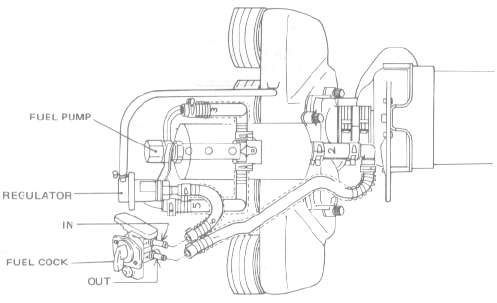

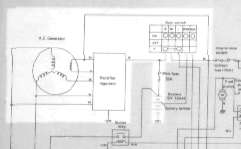

The Yamaha turbo system is made up of three basic systems: the fuel system, the intake system and the exhaust system. These systems work together to Increase the performance and efficiency of the engine.

The fuel system must provide fuel to the carburetors under normal operation as well as during boost operation. Due to the precision nature of many components in the turbo system, it is imperative that the fuel tank, fuel filters and carburetors be completely free of rust, fuel residue and other contaminants.

The intake system allows the engine to draw clean air through the air cleaner at low speeds, and forces pressurized air from the turbocharger compressor to the engine. This system must be free of pressure leaks to perform its function properly.

The exhaust system drives the turbocharger turbine. The exhaust joints should be tight to prevent exhaust pressure leakage, and the turbocharger must function properly.

Since these three systems are interdependent a problem with any one or more components in any of the three systems can cause a performance problem with the entire turbo system.

VERIFY THE PROBLEM

Diagnosing performance problems requires that you first determine the cause of the problem by verifying the symptoms. Usually, performance problems fall into three categories: the motorcycle acts like It Is running out of fuel, it overflows fuel (runs rich), or it runs poorly while on boost. By using customer information, a comprehensive test ride and a logical troubleshooting procedure, you should be able to locate and correct the problem quickly and easily.

Normally, fuel overflow is due to a check valve which is stuck open or a pressure regulator which Is stuck closed. Fuel overflow can also be caused by a clogged petcock filter. Also be certain that the carburetors are properly cleaned, that the needle valves seal properly, and that the float levels are properly set.

NOTE: The proper float level specification should be 21.5 + 5mm.

Fuel system problems may also be causing high performance problems. If there is a high performance problem, look for conditions such as a plugged fuel tank cap vent or Improper carburetor adjustments in addition to the fuel system troubleshooting procedures described below.

FUEL SYSTEM TROUBLESHOOTING

If you have determined that the motorcycle acts as If It Is running out of fuel, running rich, or It runs poorly while on boost, perform the following tests.

NOTE: All of the above turbo conditions are usually caused by fuel system contamination.

This procedure requires extensive handling of gasoline. Gasoline Is extremely flammable. To avoid severe injury, do not allow open flames, sparks, cigarettes, or any other sources of Ignition near the area In which you are working.

FUEL FILTER TESTS

1. Remove the tank cover and side panels.

2. Turn the petcock valve to the "OFF" position.

3. Remove the output hose from the petcock.

4. Connect a 5/16-inch ID hose approximately two feet long to the outlet side of the petcock.

5. Place the other end of the hose in a clean drain pan.

6. Turn the petcock to the "ON" position; a normal gravity flow of fuel should be seen.

7. Turn the petcock valve to the reserve position.

Again, a normal gravity flow of fuel should be seen.

NOTE: Observe the fuel (towing Into the pan. It contaminants are present In the fuel flowing into the drain pan with the petcock In the reserve position, the entire fuel system Is most likely contaminated and will need to be clean.

8. If fuel did not flow correctly in either of the above tests, repeat the test procedure with the fuel cap removed. If the fuel flow improves, clean or replace the fuel cap If the flow did not improve the petcock, petcock litters, and the fuel tank will need to be cleaned thoroughly. Refer to Bulletin M84-016.

9. Remove the conical filter located in the inlet side of the fuel pump. Clean if necessary. If contaminants are present in this filter a lean condition could occur, especially under boost conditions.

10. Reconnect the proper fuel lines to the petcock and fuel pump.

FUEL PUMP PRESSURE TEST

If the problem that was originally verified still exists after performing the fuel filter tests, the fuel pump pressure will need to be tested.

1. Disconnect the output hose from the fuel pump assembly.

2. Connect a 5/16-inch ID hose, approximately two feet long, to the fuel pump fitting.

3. Place a graduated container, such as a Ratio Rite™ cup, underneath the hose coming from the fuel pump.

4. Turn the ignition on, place the transmission in gear and push the starter button. The engine should not turn over, but the fuel pump should operate and pump fuel.

5. The fuel pump should pump a minimum of 300cc of fuel in 15 seconds. If it does not pump enough fuel in the test the fuel pump should be replaced.

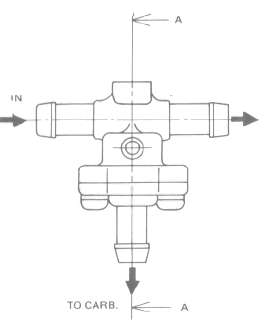

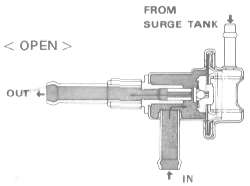

CHECK VALVE AND PRESSURE REGULATOR TEST

Again, if the problem has not been located with the above tests, proceed to test the check valve and pressure regulator.

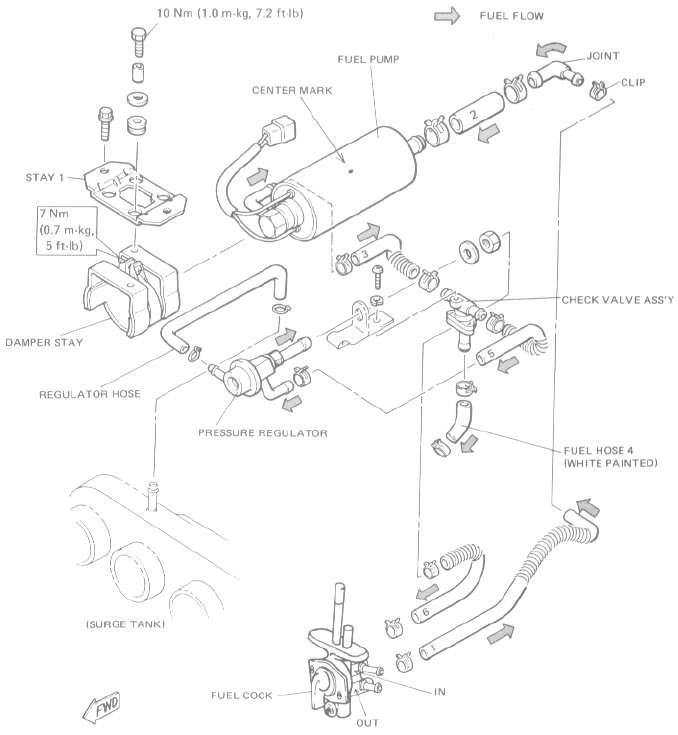

1. Remove the fuel tank and fuel pump

2. Disconnect the lower hose from the check valve and connect a two-foot length of 5/164nch ID fuel line to the lower fitting of the check valve.

3. Connect another two-foot length of fuel line to the pressure regulator outlet fining. Run both of these fuel lines into a drain pan.

4. Reinstall the fuel pump and fuel tank and connect the fuel outlet hose to the "OUT" fitting of the petcock.

5. Plug the "IN" fitting of the petcock to prevent fuel leakage. Recheck all lines to make sure they are properly connected to avoid fuel leakage.

6. Turn the petcock to the "ON" position. No fuel should flow when the engine is not running.

7. Turn the petcock to the "RESERVE" position. Again, no fuel should flow when the engine is not running. If fuel flows out of the check valve, then the check valve is defective and should be replaced. The same is true if the fuel leaks from the pressure regulator: If It leaks, replace It.

8. Turn the Ignition on. place the transmission in gear and push the starter button. The fuel pump should operate and pump fuel but the engine should not turn over.

9. Fuel should be pumped out of the check valve outlet hose, but not from the pressure regulator. If the pressure regulator does allow fuel to flow, then It should be replaced.

10. Place a graduated container, such as a Ratio Rite™ cup, under the check valve outlet hose. Push the starter button as before and pump fuel into the container for exactly 15 seconds. The amount of fuel pumped should be at least 300ca If It is less, replace the check valve.

11. Perform this same test with the check valve outlet hose plugged closed. The output through the pressure regulator outlet hose should also be at least 300cc for 15 seconds of pumping. If it Is less, replace the pressure regulator.

INTAKE SYSTEM TROUBLESHOOTING

Intake system problems, such as low or no boost pressure, can be caused by a leak in the pressurized system. Usually, a problem here is found by a quick visual inspection of the system's components.

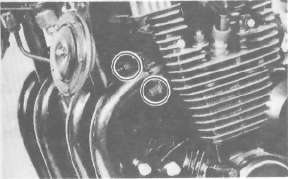

1. Inspect all of the exhaust system joints for leaks and tighten the clamps as necessary. It is usually helpful to remove the exhaust clamp bolts and coat the threads with anti-seize compound. This allows better tightening and helps prevent thread seizure or stripping. Also replace any gaskets that are damaged or worn.

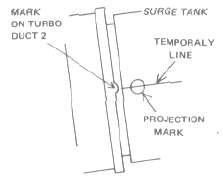

2. Inspect the intake air ducts between the air box and the compressor, and from the compressor to the surge tank. The connections of these ducts must be tight to prevent air pressure leaks, and to prevent foreign material from entering the compressor or the engine

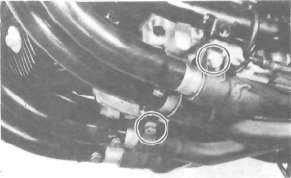

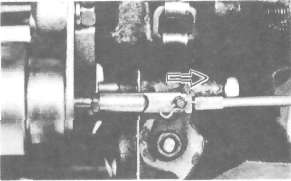

3. Poor boost pressure many times Is caused by a wastegate that is partially stuck open, usually as a result of carbon deposits. These deposits will need to be scraped clean to allow normal closing. To test for this condition, rev the engine to 4.000 rpm and check for exhaust gas exiting the right muffler. If there Is, then the wastegate is stuck open.

4. The wastegate may also be held open by a rusty wastegate actuator pivot bearing. The best method of checking wastegate actuator movement is to locate the 10mm hex nut on the top of the turbocharger and turn the nut with a wrench. Only a small space is available to work In, but sufficient movement can be made to move the actuator In and out.

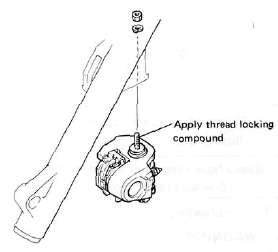

NOTE: While moving the actuator, spray Yamaha "GP Lube" on the shaft and bushings for lubrication. Some actuators may actually be frozen In place It this is a problem, spray the "GP Lube" liberally on the bushing and work the actuator in and out until It works freely. Turbocharger removal should not be necessary unless the actuator is badly rusted. It is recommended that this procedure be performed during normal tune-up maintenance to prevent sticking problems at a later date.

5. It poor boost pressure is still a problem after the above steps have been followed, the surge tank should be inspected for leakage at the reed valves, relief valve and drain valve Test the drain valve for leakage by holding the end of the drain hose in a cup of water. While on boost, no air leakage should be noticed (bubbles in the water). The reed valves and relief valve must be checked visually for proper closing.

6. Poor boost pressure can also be caused by glazed spark plugs, inoperative boost or knock sensors, or fuel delivery problems.

NOTE: Spark plugs should be replaced whenever performance problems are encountered. Due to the high performance of the turbo engine, spark plug glazing is a greater possibility than with other engines.

If these procedures do not solve the poor boost pressure problem, contact your Regional Technical Advisor.

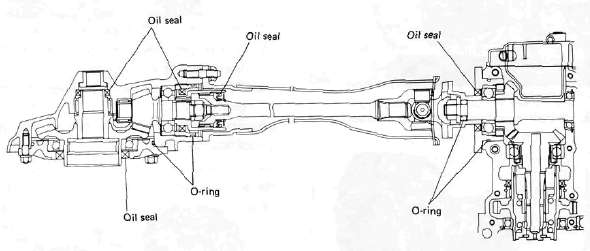

EXHAUST AND TURBO LUBRICATION TROUBLESHOOTING

Exhaust (or turbocharger) and lubrication problems usually fall Into two categories: oil leakage from the exhaust and lack of lubrication at the turbocharger.

OIL LEAKAGE FROM EXHAUST

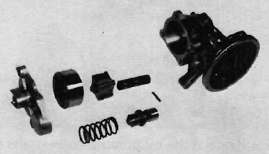

Oil leakage from the exhaust, whether on a new machine or one that has been In use, is usually due to the old check valve being stuck in the open position. This allows oil to run into the turbocharger and then into the exhaust pipes. This can occur because the seal in the turbocharger is similar to a piston ring; It only seals when the turbocharger is running. Oil can drain from the turbo Into the pipes or be pushed Into the surge tank when the turbo operates. Inspect the check valve by removing and disassembling it. Thoroughly clean the valve, and inspect the spring/ball for proper closing.

Other causes of oil In the exhaust or surge tank can be due to a blocked oil scavenge (return) line or a poor O-ring seal between the feed and scavenge rotors in the oil pump assembly. A defective oil ring seal in the turbocharger Is possible but always verify that the check valve and oil lines are functioning properly before replacing the turbocharger. Finally, any oil In the exhaust pipes, joint, or mufflers must be cleaned out before running the engine Otherwise excessive smoking and carbon build-up will occur r within the exhaust system.

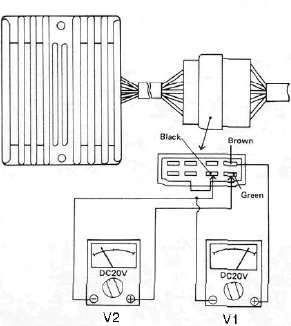

LUBRICATION FAILURES