Front fork and rear shock absorber adjustment

Front fork:

1. Elevate the front wheel by placing the motorcycle on the center stand.

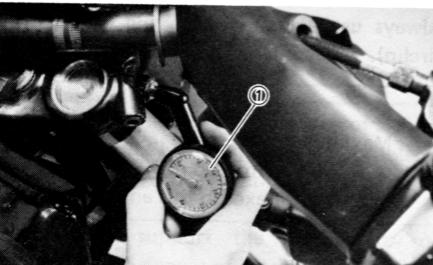

NOTE:

When checking and adjusting the air pressure, there should be no weight on the front end of the motorcycle.

2. Remove the air valve caps from each fork.

3. Using the air gauge, check and adjust the air pressure.

If the air pressure is increased, the suspension becomes stiffer and if decreased, it becomes softer. To increase:

Use a manual air pump or other pressurized air supply. To decrease: Replace the air by pushing the valve pin.

1. Air gauge

Standard air pressure:

0.4 kg/cm2 (5.7 psi) Maximum air pressure:

2.5 kg/cm2 (36 psi) Minimum air pressure: Zero

* Never exceed the maximum pressure, or oil seal damage may occur.

* The difference between both the left and right tubes should be 0.1 kg/cm2 (1.4 psi) or less.

4. Install the air valve caps securely.

Rear shock absorber:

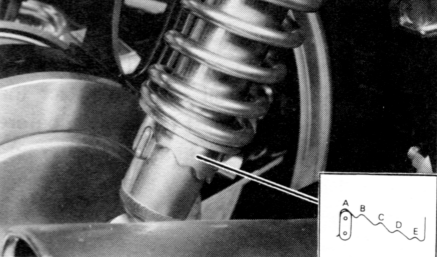

1. Spring preload

If the spring seat is raised, the spring becomes stiffer and if lowered, it becomes softer.

Standard position — A A. position — Softest E. position — Stiffest

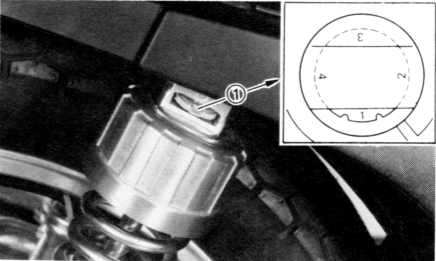

2. Damping force

Turn the damping force adjuster by your fingers to increase or decrease the damping force. If it is difficult to turn it with your fingers, use a screw driver.

Standard position — No. 1

No. 1 — Minimum damping force No. 4 — Maximum damping force

NOTE:

When adjusting the damping force, the adjuster should be placed in the clicked position. If not, the damping force will be set to the maximum (No. 4).

Always adjust both the right and left absorbers to the same position.

1. Damping force adjuster

Recommended combinations of the front fork and the rear shock absorber.

Use this table as guidance to meet specific riding conditions and motorcycle load.

|

\ |

Front fork |

Rear shock absorber |

Loading condition |

Air pressure |

Spring seat |

Damping adjuster |

Solo rider |

With passenger |

With accessory equipments |

With accessory equipments and passenger |

1. |

0.4 ~ 0.8 kg/cm2 (5.7 ~ 11.4 psi) |

A~C |

1 |

O |

2. |

0.4 ~ 0.8 kg/cm2 (5.7-11.4 psi) |

A~C |

2 |

O |

O |

3. |

0.4 — 0.8 kg/cm2 (5.7 ~ 11.4 psi) |

C~E |

3 |

O |

O |

4. |

0.8-1.2 kg/cm2 (11.4-17.1 psi) |

E |

4 |

O |

O |

WARNING:

The anti-dive setting must be the same on both anti-dive units.

Anti-dive adjustment

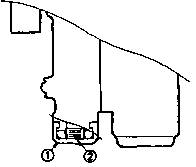

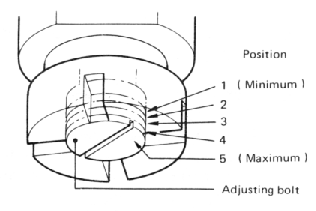

1. Remove the rubber cap from the bottom of the anti-dive unit.

2. Observe the head of the adjusting bolt through the machines slot{s) in the bottom of the anti-dive unit. In the standard position, four lines will be visible on the adjusting bolt head. Consult the fork adjustment chart below to determine the proper setting.

1. Rubber cap 2. Adjusting bolt

To decrease the anti-dive effect, turn the adjusting bolt counter-clockwise until the head appears level to the top of the machined slot(s).

WARNING

When the first line appears in the machined slot(s), the adjusting bolt will bottom in the anti-dive unit and a resistance will be felt. Do not attempt to turn the adjusting bolt beyond this point, or the anti-dive unit will be damaged.

1. Machined slot

4. To increase the anti-dive effect, turn the adjusting bolt clockwise.

5. Replace the rubber cap.

WARNING

The anti-dive settings must be the same on both anti-dive units. Hence, be sure to perform the above procedure on both anti-dive units.

|

Adjusting bolt |

Loading condition |

Solo rider |

With accessory equipments or passenger |

With accessory equipments and passenger |

1(head flush) |

O |

|

|

2 |

O |

O |

|

3 |

O |

O |

O |

4 |

|

O |

O |

5(4 lines showing) |

|

|

O |

- Printer-friendly version

- Log in to post comments