Chapter 4, COOLING SYSTEM

- Read more about Chapter 4, COOLING SYSTEM

- Log in to post comments

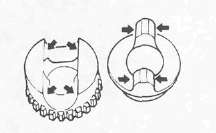

INSPECTION

1. Check

• teeth of middle gear for discoloration/Pitting/Wear. If necessary, replace all middle gears as a set.

• Damper cam surfaces for wear/Unsmooth action. Replace if necessary.

2. Check bearing movement. Rotate the race by finger and replace if rough.

REMOVAL

Middle Drive Gear

NOTE:

Middle drive gear and its shims can be removed without separating the engine.

1. Remove the clutch cover. Refer to "ENGINE DISASSEMBLY."

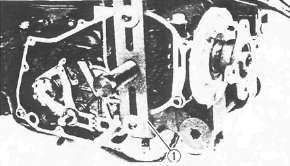

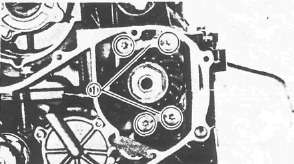

GEAR LASH MEASUREMENT

NOTE:

The middle gear lash can be checked only when the gears are installed in the crankcase.

1. Attach:

• Middle Drive Pinion Holder (90890-04051) 1 .

MIDDLE GEAR SERVICE

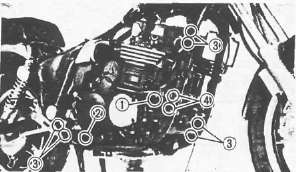

1. Refer to engine removal. Reverse those removal steps that apply.

2. Tighten engine mounting bolts

Engine Mounting Bolt: Front 1: 42 Nm (4.2 m-kg, 30 ft-lb)

Rear 2 : 90 Nm (9.0 m-kg, 65 ft-lb)

Down Tube 3 , Bracket 4 : 33 Nm (3.3 m-kg, 24 ft-lb)

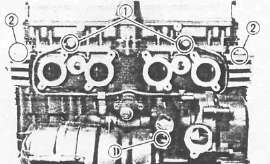

RADIATOR PIPES, CARBURETOR JOINT, AND OIL DELIVERY PIPE

1. Install:

• Union bolt with copper washer 1

• Cylinder head side cover 2

Oil Delivery Pipe: 21 Nm (2.1 m-kg, 15 ft-lb)

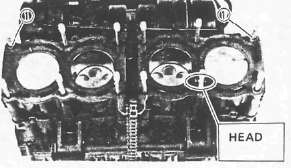

CYLINDER HEAD

1 Check bolt

2 Dowel pin

3 Camshaft case gasket

4 Valve guide

5 O-ring

6 Camshaft case

7 Cylinder head

8 Oil pipe

[A] Be sure the "UP" mark faces upward.

PISTON AND CYLINDER

1 Cylinder head gasket

2 Dowel pin

3 Drain bolt

4 Oil delivery pipe

5 O-ring

6 Cylinder base gasket

7 Piston ring

8 Piston pin clip

9 Piston pin

10 Copper washer

1. Install:

• Piston rings (onto the pistons)

MIDDLE GEAR

1. Install:

• Bearing retainers 1

• TORX screws (New)

• Oil level maintaining plug

Bearing Retainer: 25 Nm (2.5 m-kg, 18 ft-lb)