Clutch and Shifter Reassembly

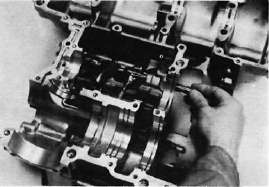

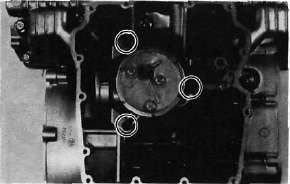

5. Clutch assembly

a. Install the thrust plate onto the transmission main axle.

1. Thrust plate

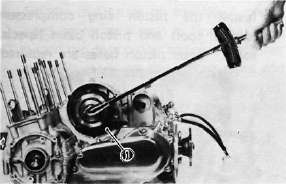

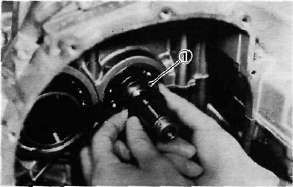

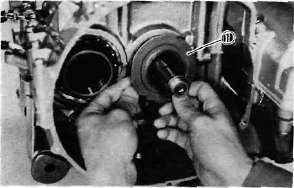

b. Install the oil pump drive sprocket onto the main axle without the spacer collar and place the oil pump drive chain on its sprocket.

1. Oil pump drive sprocket

- Read more about Clutch and Shifter Reassembly

- Log in to post comments