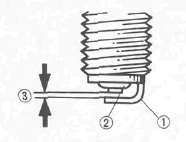

SPARK PLUG

1. Remove spark plugs

2. Inspect:

• Electrode (1) for wear/damage.

• Insulator color (2)

3. Measure the plug gap (3) using a Wire Gauge or Feeler Gauge. Regap as reqired.

Plug Gap: 0.6 - 0.7 mm (0.024 - 0.028 in)

Clean the plug with a spark plug cleaner if necessary.

Standard Spark Plug: DR8ES-L (NGK) X24ESR-U (NIPPONDENSO)

Before installing a spark plug, clean the gasket surface and plug surface.

4. Tighten Spark plug(s) to 17.5 Nm (1.75 m-kg, 12.5 ft-lb)

NOTE:

Finger-tighten the spark plug(s) before torquing to specification.

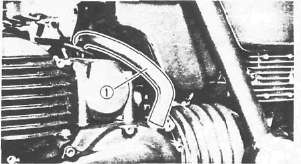

CRANKCASE VENTILATION SYSTEM

1. Inspect the crankcase ventilation hose (1). Replace damaged hoses.

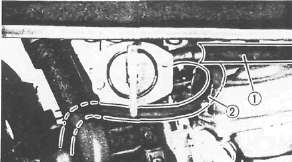

FUEL LINE

1. Inspect:

• Fuel hose (1)

• Vacuum hose (2)

Replace damaged hoses.

INTAKE MANIFOLD

1. Tighten:

• Carburetor clamps

• Carburetor joint bolts

2. Inspect:

• Carburetor joint

• Gaskets

Replace if necessary.

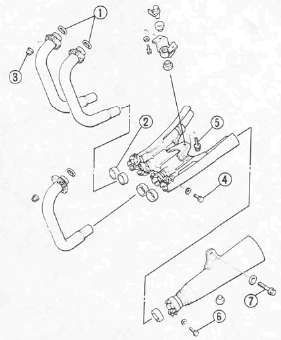

EXHAUST SYSTEM

1. Inspect:

•Exhaust pipe gasket(s) (1)

• Muffler clamp gasket(s) (2)

Damage > Replace.

Exhaust gas leakage > Repair.

2. Tighten:

• Exhaust pipe bolts

• Muffler bolts

Exhaust Pipe Flange (3) :10 Nm(1.0m-kg, 7.2ft-b)

Exhaust Pipe Clamp (4) :20 Nm (2.0 m-kg, 14 ft-lb)

Exhaust Chamber Mount (5): 25 Nm (2.5 m-kg, 18 ft-lb)

Muffler Clamp (6): 20 Nm (2.0 m-kg, 14 ft-lb)

Muffler Bracket (7) 20 Nm (2.0 m-kg, 14 ft-lb)

- Printer-friendly version

- Log in to post comments