Transmission -- Inspection and Repair

L. Transmission

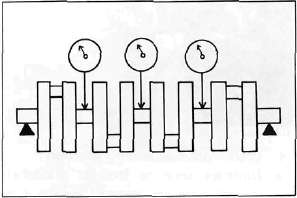

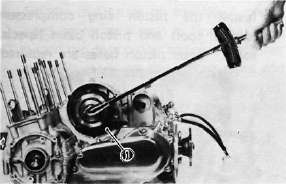

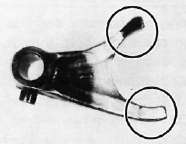

1. Inspect each shift fork for signs of galling on gear contact surfaces. Check for bending. Make sure each fork slides freely on its guide bar.

2. Roll the guide bar across a surface place. If the bar is bent, replace.

- Read more about Transmission -- Inspection and Repair

- Log in to post comments