Cylinder and Cylinder Head Disassembly

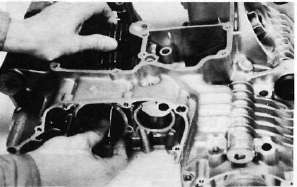

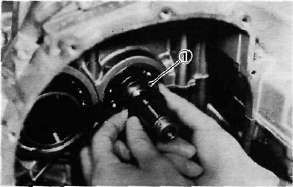

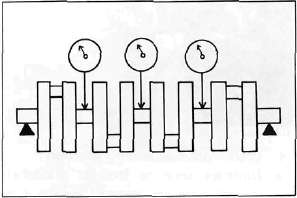

13. Remove the front cylinder holding nut and remove the cylinder assembly. It may be necessary to tap the cylinder lightly to loosen it from the base gasket.

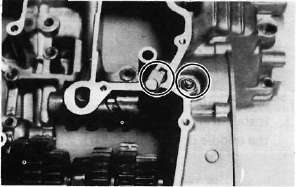

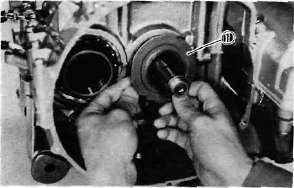

14. Remove the rear cam chain guide by loosening the holding bolt.

- Read more about Cylinder and Cylinder Head Disassembly

- Log in to post comments