Special Tools and Troubleshooting

Special Tools and TroubleshootingThe following special tools are not available but can be constructed for the final gear disassembly and assembly:

PRESS TOOL NO. 1

PRESS TOOL NO. 2

GEAR CASE HOLDING TOOL

Troubleshooting

1. The following conditions may indicate damaged shaft drive components:

|

Symptoms |

Possible damaged areas |

|

1. A pronounced hesitation or "jerky" movement during acceleration, deceleration, or sustained speed. (This must not be confused with engine surging or transmission characteries). |

A. Damage to bearings. |

|

B. Improper gear lash. |

|

|

C. Gear tooth damage. |

|

|

2. A "rolling rumble" noticeable at low speed; a high-pitched whine; a "clunk" from a shaft drive component or area. |

D. Drive flange/universal joint bolts loose. |

|

3. A locked-up condition of the shaft drive mechanism; no power transmitted from engine to rear wheel. |

E. Broken drive-shaft. |

|

F. Disconnected flange/universal joint connection. |

|

|

G. Broken gear teeth. |

|

|

H. Seizure due to lack of lubrication. |

|

|

I. Small foreign object lodged between moving parts. |

NOTE: Damage areas A, B, and C above may be extremely difficult to diagnose. The symptoms are quite subtle and difficult to distinguish from normal motorcycle operating noise. If there is reason to believe component(s) are damaged, remove component(s) for specific inspection.

2. Inspection notes

a. During coasting, accelerating or decelerating, the "rolling rumble" will increase with rear wheel speed, not engine or transmission gear speeds. However, such noise may also be due to wheel bearings.

b. Noise that varies with acceleration and deceleration: Following incorrect reassembly, a condition of too-little gear lash may produce a whine during deceleration.

CAUTION: Too-little gear lash is extremely destructive to gear teeth. If a test ride following reassembly indicates this condition, stop riding immediately to minimize damage to gears.

c. A slight "thunk" must be distinguished from normal motorcycle operation. It will be most noticeable at low speed and could indicate broken gear teeth.

WARNING: If broken gear teeth are suspected, stop riding immediately. This condition could lead to locking-up of the shaft drive assembly and result in harm to a rider.

d. If the drive flange/universal joint bolts are slightly loose, a "clunk" may be felt when slowly taking off, or when changing from slow acceleration to slow decelration. At high speed this will result in vibration.

WARNING: Do not continue riding a motorcycle suspected of having loose flange/universal joint bolts. The components may break, causing injury to a rider.

3. Troubleshooting chart

Where Basic Conditions "a" and "b" above exist, consider the following chart:

|

Elevate and spin front wheel. Feel for wheel bearing damage. |

Yes |

Replace wheel bearing. (See CHAPTER 5 "FRONT WHEEL") |

|

I No |

||

|

Check rear wheel. Feel for bearing damage. |

No |

Rear wheel bear-inbgs and shaft drive bearings probably not damaged. Repeat test or remove individual components. |

|

Yes |

||

|

Remove rear wheel. Check for wheel bearing damage. |

Yes |

Repelace rear wheel bearing. (See "REAR WHEEL" section in this chapter.) |

|

No |

||

|

Remove drive shaft components. |

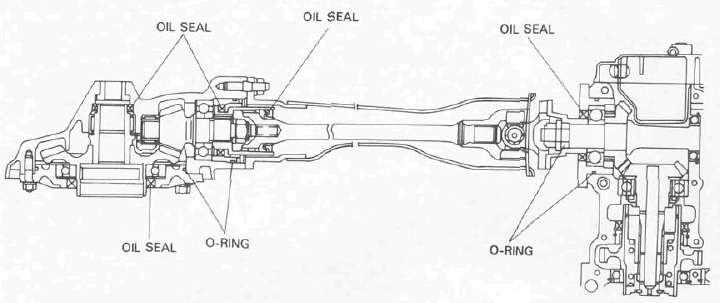

4. Oil leak inspection

If a shaft drive component is suspected of leaking oil, first thoroughly clean the entire motorcycle. The spparent location of an oil leak on a dusty motorcycle may be misleading. Dry the motorcycle and apply a leak-localizing compound or a dry-powder spray that will limit the flow of any leaking oil. Operate the motorcycle prepared in this way for the distance necessary to precisely locate the leak. There are the possibilities that a component housing may have been damaged by road debris or an accident, or a gasket or seal may be cracked or broken. However, on new or nearly new motorcycle an apparent oil leak may be the result of a rust-preventive coating or excess assembly lubrication of seals. Always clean the motorcycle and recheck the suspected location of any apparent leakage.

5. Checking drained oil

Whenever a problem is suspected in either the middle or final gear assemblies, drain and inspect the oil. Metal particles on the drain plug or in the oil could indicate a bearing seizure or other problem in the component. However, a small amount of metal particles in the oil is normal.