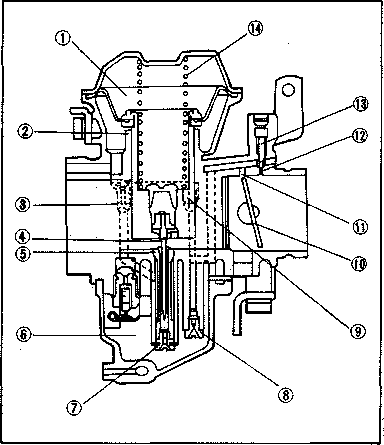

CARBURETOR

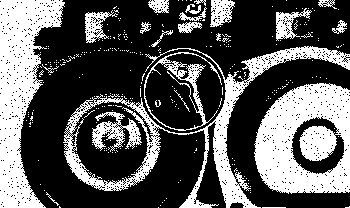

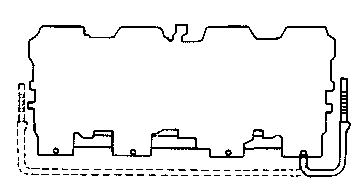

Section View

| 1 | Diaphragm | 8 | Pilot Jet |

| 2 | Piston valve | 9 | Pilot Air Jet |

| 3 | Main air jet | 10 | Throttle Valve |

| 4 | Jet needle | 11 | By-pass hole |

| 5 | Needle jet | 12 | Pilot Outlet |

| 6 | Float chamber |

13 | Pilot Screw |

| 7 | Main jet | 14 | Spring |

Specifications

| Main jet | #106 |

| Jet needle | Y-18 |

| Pilot jet | #41 |

| Starter jet | #43 |

| Fuel level | 1.0 ± 1 mm (0.0394 ± 0.039 in.) |

| Pilot screw | Preset |

| Float valve seat | 02.0 |

| Engine idle speed | 1,100 +50 r/min |

CAUTION: The pilot screw settings are adjusted for maximum performance at the factory attempt to change these settings as any alteration will decrease engine performance.

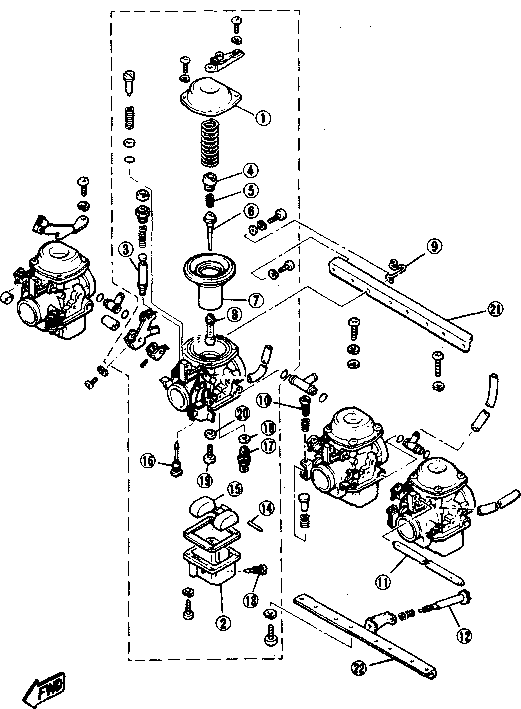

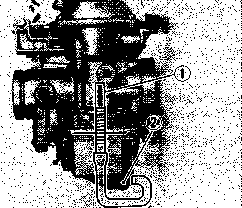

CARBURETOR

| 1. | Vacuum chamber cover | 12. | Throttle stop screw |

| 2. | Float chamber cover | 13. | Drain screw |

| 3. | Starter plunger | 14. | Float pin |

| 4. | Jet needle cover | 15. | Float |

| 5. | Set spring | 16. | Pilot jet |

| 6. | Jet needle | 17. | Float valve |

| 7. | Vacuum piston | 18. | Float valve washer |

| 8. | Main nozzle | 19. | Main jet |

| 9. | Clutch wire clip | 20. | Main jet washer |

| 10. | Synchronizing screw | 21. | Upper support plate |

| 11. | Starter lever shaft | 22. | Lower support plate |

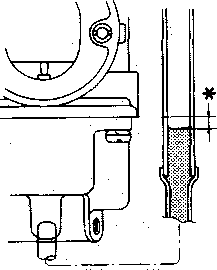

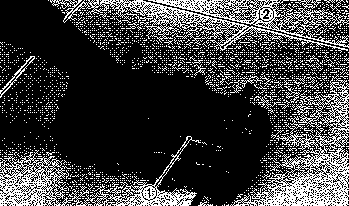

FUEL LEVEL

* 1.0 ± 1 mm (0.0394 ± 0.039 in)

Disassembly

CAUTION: Separation of the carburetor is not recommended. Usual disassmebly for cleaning and inspection is not necessary to separate the carburetors. The carburetor body support screws are locked with a locking compound such "LOCTITE". If the carburetors are separated, misalignment will result.

Remove:

• Vacuum chamber cover

• Vacuum piston

• Jet needle

• Main air jet 1

• Pilot air jet 2

• Main nozzle

• Starter plunger

Remove:

• Float chamber cover

• Pilot jet 1

• Main jet 2

Remove:

• Float pin 1

• Float

• Float valve

• Float valve seat

Inspection

Check:

• Carburetor body and fuel passage

If contaminated: Wash carburetor in petroleum-based solvent (Do not use any caustic carburetor cleaning solution). Blow out all passages and jets with compressed air.

• Floats

If damaged, replace.

Check:

• Float needle valve and seat

Wear, contamination -» Replace as a set.

Check:

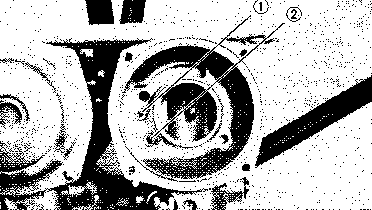

• Vacuum piston and rubber diaphragm

Scratches (piston), Tears (diaphragm) -> Replace as a set.

• Jet needle

Bends, wear -> Replace.

Check:

• Starter plunger

Wear, damage -> Replace.

Assembly

Reverse disassembly steps. Pay close attention to installation of vacuum piston diaphragm and location of each jet.

NOTE: Note position of tab on diaphragm. This tab must be placed in the cavity of the carburetor body during assembly.

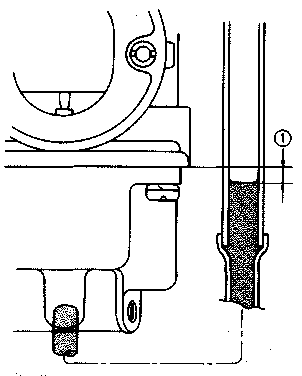

If the carburetors are separated, place the carburetors on a surface plate 2 and install lower 1 and upper support plate.

Apply loctite ® Stud N' Bearing Mount (red) to securing screws.

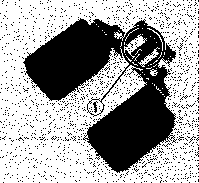

Fuel level Adjustment

NOTE: Place motorcycle on level surface before checking fuel level.

Connect:

• Fuel level gauge 1 or 6 mm (0.24 in.) vinyl pipe.

Place:

• Fuel level gauge to carburetor mixing chamber body.

Loosen:

• Drain screw 2 .

Set:

• Fuel cock to "ON" or "RES" and start engine. Stop it after a few minutes.

Check:

• Fuel level 1 should be within specified range.

Fuel level

1.0 ± 1 mm (0.0394 ± 0.039 in.) below from the carburetor mixing chamber body edge.

NOTE: Fuel level of each left and right side carburetor shouled be equal. If not, place a suitable size of wooden piece or the like under the center stand and adjust then check fuel level again.

• Remove carburetors and check fuel valve and float assembly if fuel level is not within specified range.

• If no damage is found in these parts, adjust float level by slightly bending tang 1 of float. Recheck fuel level.

• Repeat these steps for other carburetors.

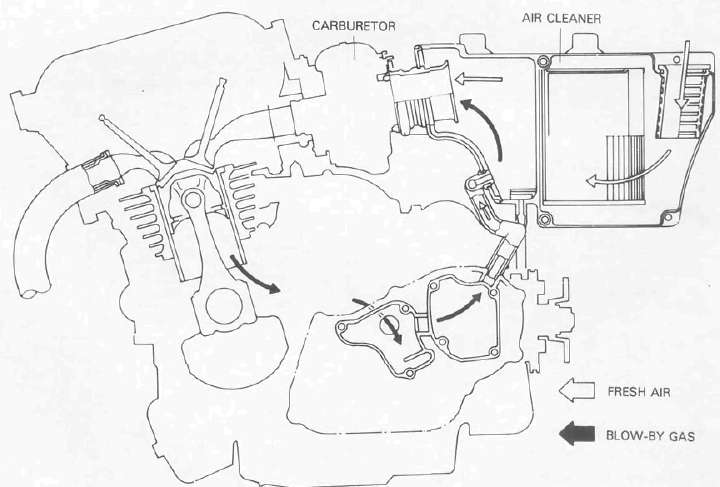

AIR CLEANER AND CRANKCASE VENTILATION SYSTEM

Refer to AIR FILTER for the air cleaner maintenance.

- Printer-friendly version

- Log in to post comments