Inspection and Repair

- Read more about Inspection and Repair

- Log in to post comments

INSPECTION

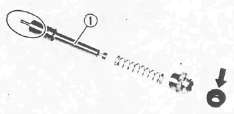

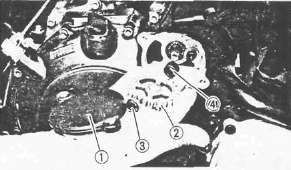

1. Inspect the starter plunger 1 for damage. Replace if damaged or worn.

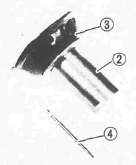

• Vacuum piston 2. Replace if scratched/worn.

•Throttle valve diaphragm 3. Replace if torn or damaged.

IGNITION SYSTEM

3 Main switch

7 Fuse "IGNITION" (10A)

8 "ENGINE STOP" switch

9 Pickup coil

10 T.C.I, unit

11 Ignition coil (#2, #3)

12 Ignition coil (#1, #4)

13 Sidestand relay

48 Battery

49 Fuse "MAIN" (30A)

SWINGARM AND REAR SHOCK ABSORBER

1 Rear shock absorber

2 Swingarm

3 Bearing

4 Oil seal

5 Collar

6 Lock washer

7 Left pivot shaft

8 Pivot cover

9 Right pivot shaft

10 Nut

11 Rubber boot

12 Spring band

PREPARATION FOR REMOVAL

1. Remove all dirt, mud, dust, and foreign material before removal and disassembly.

2. Use proper tools and cleaning equipment. Refer to CHAPTER 1, "SPECIAL TOOLS."

REMOVAL AND DISASSEMBLY

NOTE:

Be sure to drain the coolant before disassembly of the cooling system components.

1. Drain the engine oil

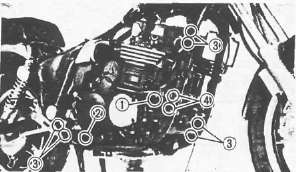

1. Refer to engine removal. Reverse those removal steps that apply.

2. Tighten engine mounting bolts

Engine Mounting Bolt: Front 1: 42 Nm (4.2 m-kg, 30 ft-lb)

Rear 2 : 90 Nm (9.0 m-kg, 65 ft-lb)

Down Tube 3 , Bracket 4 : 33 Nm (3.3 m-kg, 24 ft-lb)

|

Item |

Remarks | |||

SIGNAL SYSTEM