CLUTCH

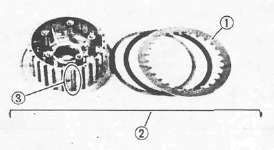

1. Inspect:

• Clutch housing dogs 1

Cracks/Pitting (edges): Moderate -> Deburr.

Severe -> Replace clutch housing.

2. Inspect

• Clutch housing bearing 2

• Spacer 3

Damage -> Replace.

NOTE:

The clutch boss contains a built-in damper beneath the first clutch friction plate (clutch plate 1). It is not necessary to remove the wire circlip 2 and disassemble the built-in damper unless there is serious clutch chattering.

3. Inspect the clutch boss spline 3 for pitting:

Moderate -» Deburr.

Severe -> Replace.

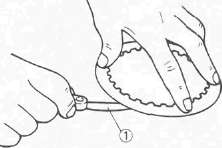

4. Place clutch plate on surface plane. For each plate:

Use feeler gauge 1 to measure maximum warpage from surface. Measure Friction plate thickness

Out of specification -> Replace clutch or friction plate as a set.

|

|

Standard |

Wear Limit |

|

Friction Plate Thickness |

3.0 mm (0.12 in) |

2.8 mm (0.11 in) |

|

Clutch Plate Warp Limit |

0 |

0.05 mm 0.0020 in) |

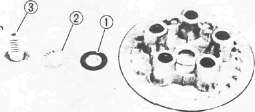

5. Inspect:

• Pressure plate

• Plate washer 1

•Thrust bearing 2

• Pull rod 3

Damage -> Replace.

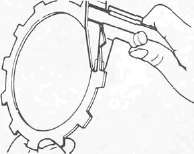

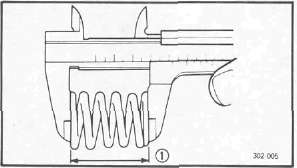

6. Measure each clutch spring free length

If any are out of specification -> Replace springs as a set.

Clutch Spring Minimum Free Length 1 : 49.0 mm (1.93 in)

- Printer-friendly version

- Log in to post comments