TRANSMISSION

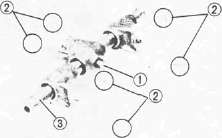

1. Inspect:

• Shift fork cam follower 1

• Shift fork pawl 2

• Guide bar 3

Scoring/Bends/Wear-> Replace.

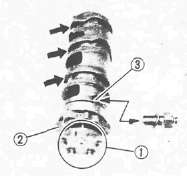

2. Inspect:

• Shift cam groove

• Shift cam dowel and side plate 1

• Shift cam stopper plate 2

• Neutral point 3

Wear/Damage -> Replace.

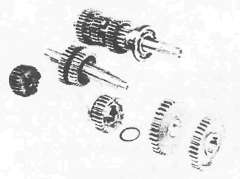

3. Measure the transmission shaft runout. Use a centering device and dial gauge. Replace shaft if bent.

Maximum Runout: 0.08 mm (0.0031 in)

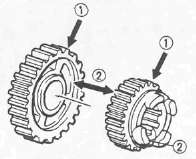

4. Inspect the gear teeth 1 for: Blue discoloration/Pitting/Wear. Inspect the mated dogs 2 for Rounded edges/Cracks/Missing portions. Replace as necessary.

Note:

Minor rounding of the dogs can be corrected by undercutting. See the article on "Repairing second gear" elsewhere on this site.

5. Check:

• Proper gear engagement (Each gear to its counter part). Incorrect-> Reassemble.

• Gear and bearing movement. Roughness-> Replace.

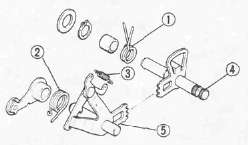

SHIFTER

1. Inspect:

• Shift return spring 1

• Stopper lever spring 2

• Shift lever spring 3

Damage -> Replace.

• Shift shaft 4

• Shift lever 5

Damage/Bends/Wear -> Replace.

CRANKCASE

1. Inspect:

• Case halves

• Bearing seat

• Fitting

Damage -> Replace.

BEARINGS AND OIL SEALS

1. Inspect each bearing. Clean and lubricate, then rotate inner race with finger.

Roughness -> Replace bearing (see Removal).

2. Inspect all oil seals. Replace any damaged or worn seals.

CIRCLIPS AND WASHERS

1. Inspect:

• Circlips

• Washers

Damage/Looseness/Bends -> Replace.

- Printer-friendly version

- Log in to post comments