Wheels

CHAPTER 5. CHASSIS

A. FRONT WHEEL

1. Place the motorcycle on the center stand.

2. Remove the front fender securing bolts and remove the fender.

3. Remove the cotter pin and wheel axle nut.

- Read more about Wheels

- Log in to post comments

CHAPTER 5. CHASSIS

A. FRONT WHEEL

1. Place the motorcycle on the center stand.

2. Remove the front fender securing bolts and remove the fender.

3. Remove the cotter pin and wheel axle nut.

Proper periodic maintenance is important. Especially important are the maintenance services

related to emissions control. These controls not only function to ensure cleaner air but

are also vital to proper engine operation and maximum performance. In the following tables

of periodic maintenance, the services related to emissions control are grouped separately.

PERIODIC MAINTENANCE EMISSION CONTROL SYSTEM

C. Piston

1. Mark each piston to aid in reassembly.

2. Place a clean towel or rag into the crank-case to keep circlips and material from falling into the engine.

3. Remove piston pin clips, piston pins, and pistons.

D. Pick-up Coil Assembly

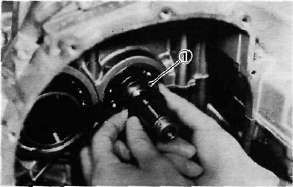

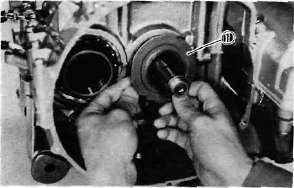

5. Clutch assembly

a. Install the thrust plate onto the transmission main axle.

1. Thrust plate

b. Install the oil pump drive sprocket onto the main axle without the spacer collar and place the oil pump drive chain on its sprocket.

1. Oil pump drive sprocket

PARTS ILLUSTRATIONS

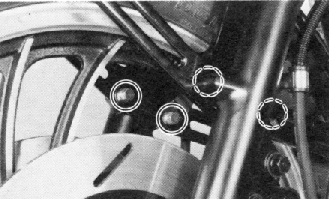

STEERING HEAD

A. Adjustment

Refer to "D. Reassembly" (below) for steering head adjustment procedure.

B. Removal

1. Remove the front wheel, front forks and handlebars.

D. CHARGING SYSTEM

B. A.C. Generator

1. Checking method.

a. Connect D.C. voltmeter to the battery terminals.

b. Start engine.

F. Cylinder

1. Inspect the cylinder walls for scratches. If vertical scratches are evident, the cylinder wall should be rebored or the cylinder should be replaced.

2. Measure cylinder wall wear as shown. If wear is excessive, compression pressure will decrease. Rebore the cylinder wall and replace the piston and piston rings. Cylinder wear should be measured at three depths with a cylinder bore gauge. (See illustration.)

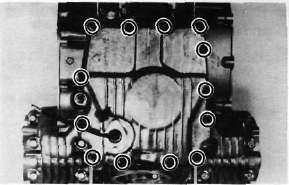

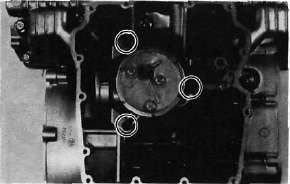

H. Oil Pump Removal and Disassembly

1. Remove the strainer cover. Note the wire harness clip position.

2. Remove the oil pump securing bolts and remove the sprocket cover and oil pump assembly.

XJ750J WIRING DIAGRAM