Engine Disassembly

- Read more about Engine Disassembly

- Log in to post comments

REMOVAL AND DISASSEMBLY

1. Drain coolant

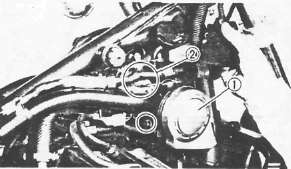

2. Remove horns 1

3. Disconnect electrical leads 2

CABLE MAINTENANCE

NOTE:

See "Maintanance and Lubrication" intervals charts. Cable maintenance is primarily concerned with preventing deterioration and providing proper lubrication to allow the cable to move freely within its housing. Cable removal is straightforward and uncomplicated. Removal is not discussed within this section.

SHAFT DRIVE

Refer to "CHAPTER 3". for the middle gear.

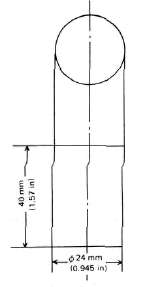

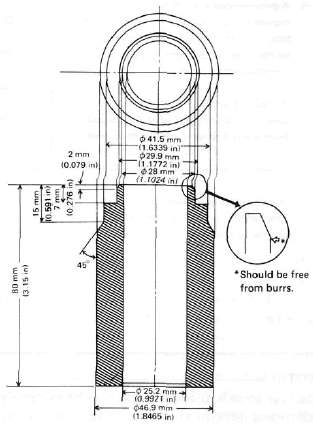

The following special tools are not available but can be constructed for the final gear disassembly and assembly:

SWITCHES

Use Pocket Tester (90890-03112) on "Ohm x 1" scale to check the switches. Replace any "shorted" or opened element.

Main Switch

|

Switch position |

MIDDLE GEAR SERVICE

COOLANT DRAINING

Do not remove the radiator cap when the engine and radiator are hot.

1. Remove:

•Cap retainer 1

Radiator cap 2

2. Place an open container under the engine.

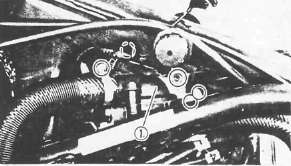

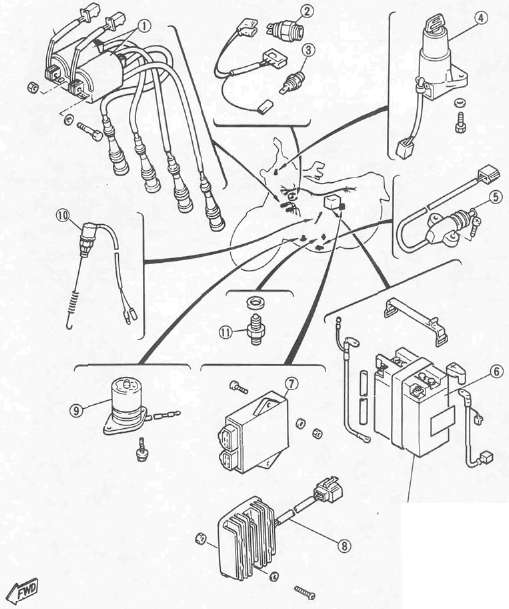

ELECTRICAL COMPONENTS 1

1 Ignition coil

2 Thermo switch

3 Thermo unit

4 Main switch

5 Sidestand switch

6 Battery

7 T.C.I, unit

8 Rectifier/Regulator

9 Oil level switch

10 Rear brake switch

11 Neutral switch

GENERAL TORQUE SPECIFICATIONS

This chart specifies torque for standard fasteners with standard l.S.O. pitch threads. Torque specifications for special components or assemblies are included in the applicable sections of this book. To avoid warpage, tighten multi-fastener assemblies in a criss-cross fashion, in progressive stages, until full torque is reached. Unless otherwise specified, torque specifications call for clean, dry threads. Components should be at room temperature.

REAR WHEEL